Automatic dispensing curing equipment and automatic production line for chargers

A curing equipment and automatic dispensing technology, applied in the direction of pretreatment surface, coating, device for coating liquid on the surface, etc., can solve the problems of reducing the production efficiency of chargers, the product quality cannot be guaranteed, etc., to reduce the land occupation area , the effect of reducing costs and reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

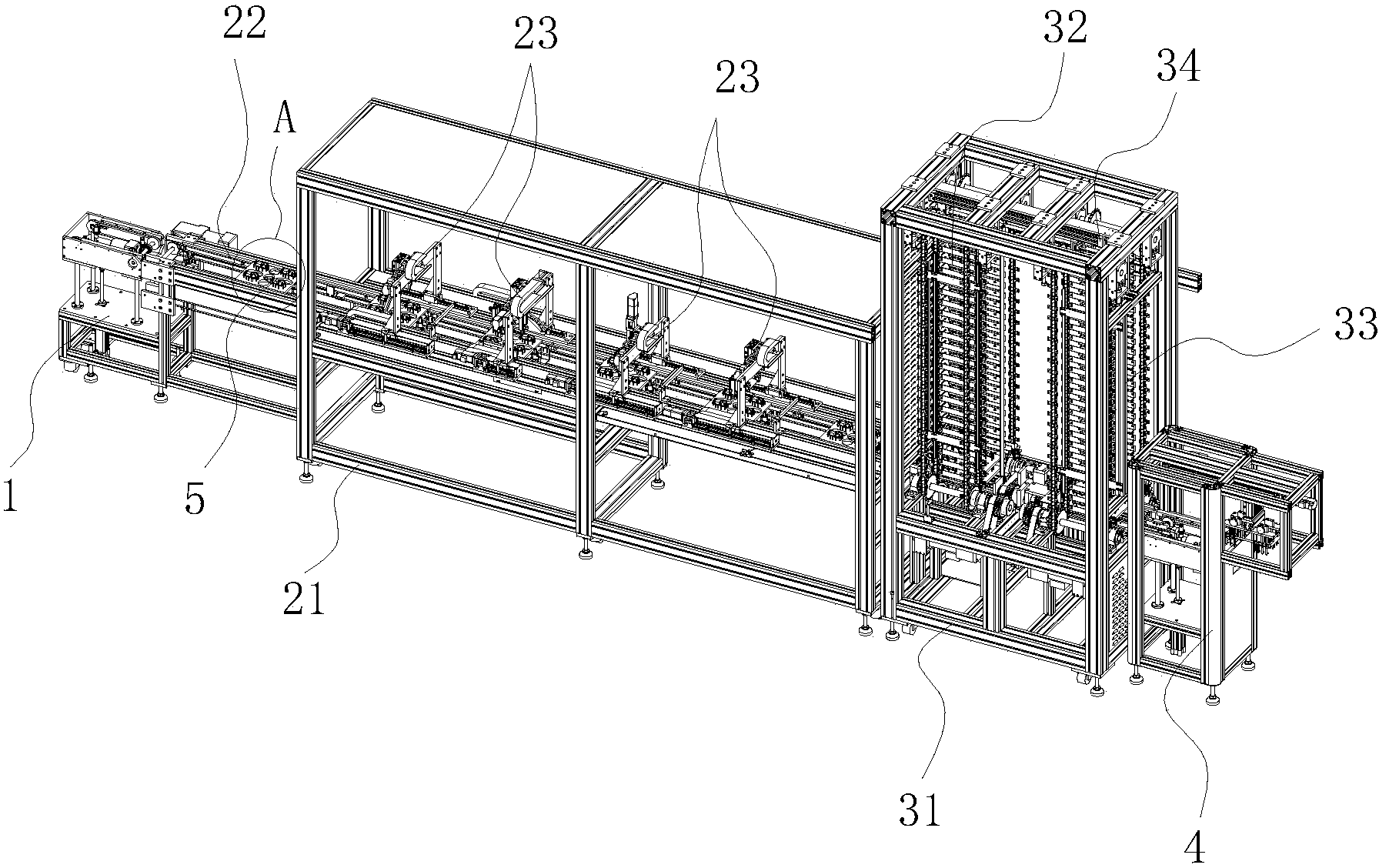

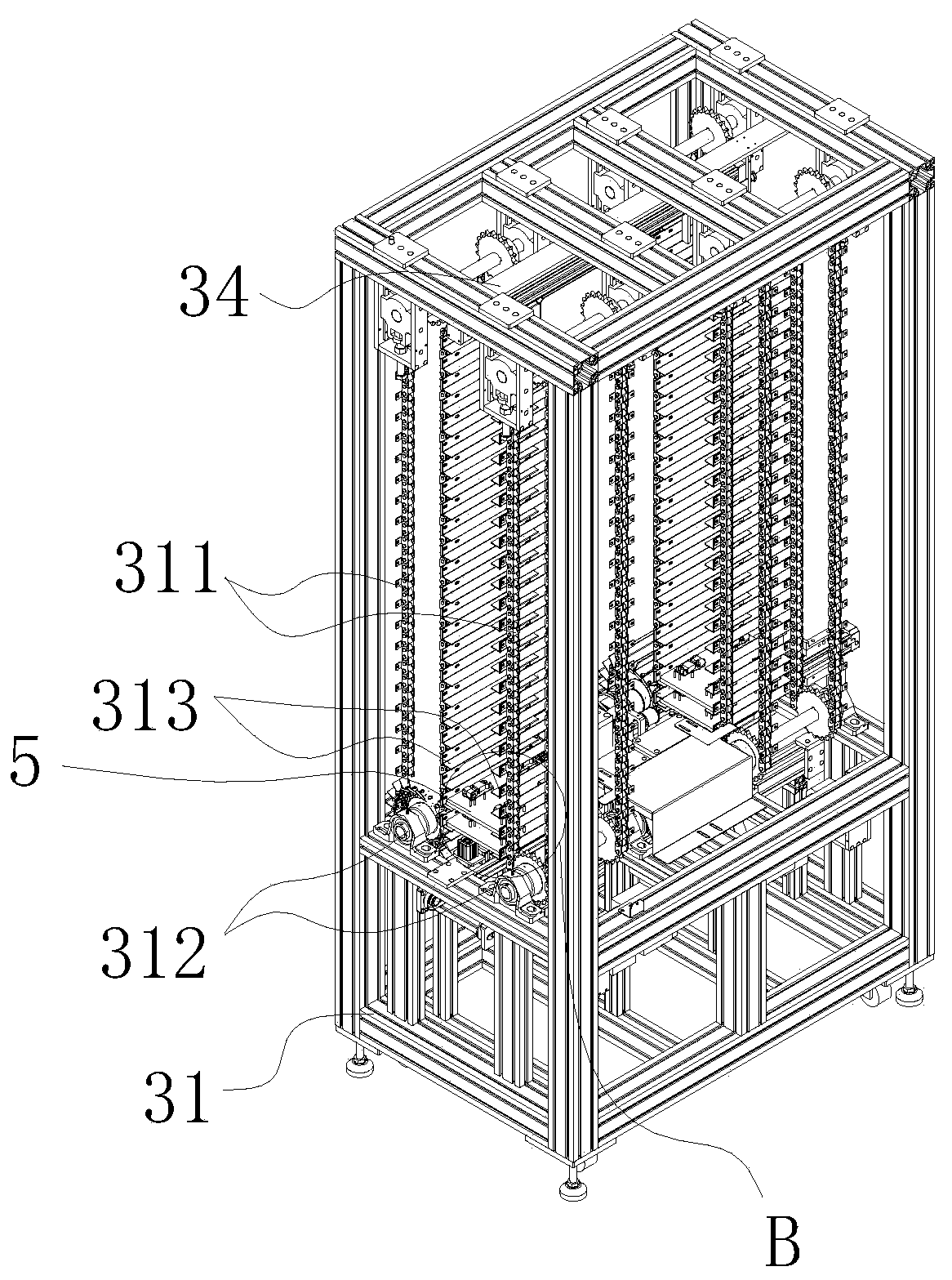

[0036] A specific embodiment of the automatic dispensing and curing equipment of the present application includes a lifting feeding device 1, a dispensing device, a curing device and a descending discharging device 4, such as Figure 1 to Figure 4 shown.

[0037] Described dispensing device comprises dispensing support frame 21, is arranged on the dispensing conveying mechanism 22 on described dispensing supporting frame 21, and is arranged on four dispensing mechanisms 23 of described dispensing conveying mechanism 22, successively It is the first dispensing mechanism 23, the second dispensing mechanism 23, the third dispensing mechanism 23 and the fourth dispensing mechanism 23. The four dispensing mechanisms 23 are equidistantly distributed, and the dispensing transmission mechanism 22 is The pulley conveying mechanism, the dispensing conveying mechanism 22 comprises a dispensing conveyor belt and a dispensing drive motor for driving the dispensing conveying belt, and a plu...

Embodiment 2

[0047] A specific implementation of the automatic charger production line of the present application, including ICT testing equipment, measuring foot height equipment, ACT testing equipment, automatic board sorting equipment and automatic dispensing and curing equipment, PCB connecting boards pass through the ICT testing equipment 1. The detection of the measuring foot height equipment and the ACT testing equipment, and the PCB of the charger is sorted out by the automatic sorting and sorting equipment, and then the PCB is transported to the automatic dispensing described in embodiment 1 Curing equipment for dispensing and curing.

[0048] Features that are not explained in this embodiment are explained in Embodiment 1, and will not be repeated here.

[0049] Further, it also includes automatic assembly equipment, pre-functional testing equipment, automatic aging testing equipment, functional testing equipment and automatic packaging equipment, after completing the dispensing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com