Control device and control method for front side guide plate of hot continuous rolling wide-band steel coiler

A side guide and hot continuous rolling technology is applied in the field of the control device of the front side guide of the hot continuous rolling wide-band steel coiler. Good coil shape, precise control, avoid stacking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

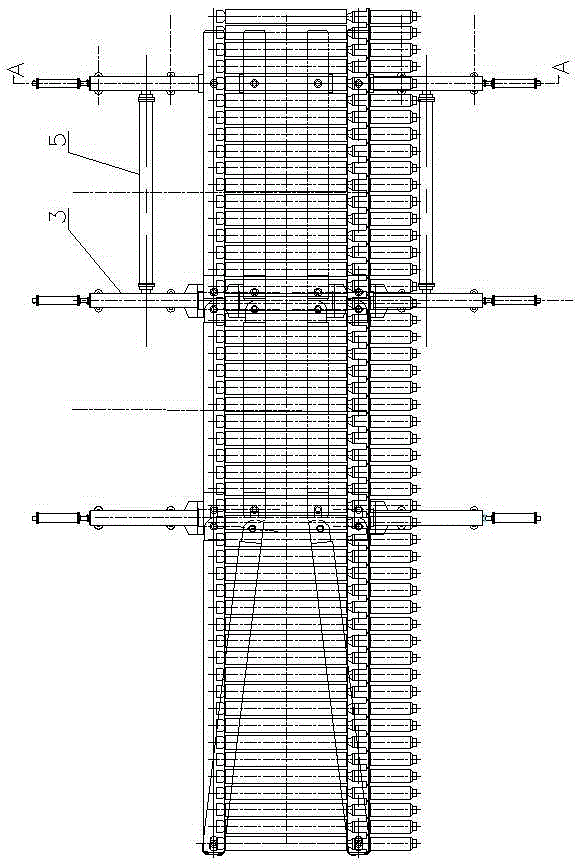

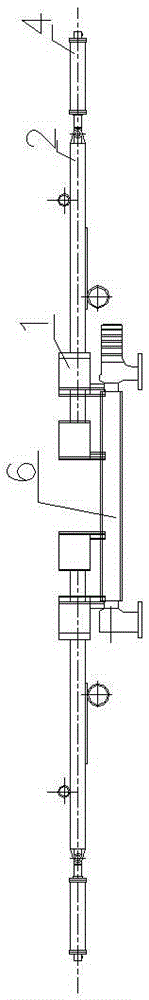

[0018] as attached figure 1 Shown: the control device of the front side guide plate of the hot continuous rolling strip steel coiler of the present invention includes the side guide plate 1 respectively installed on the operation side and the transmission side of the coiler entrance roller table 6 with the same structure, and the side guide plate 1 of the described side The guide plates are respectively connected to the traversing device 2, and the stroke of the traversing device is 1125mm. The described traversing device includes a group of push rods 3, each of which is connected to a hydraulic cylinder 4, and one of the push rods is They are connected by a synchronous coupling 5, and pressure sensors are respectively installed in the rod cavity and the plug cavity of the hydraulic cylinder.

Embodiment 2

[0020] The control device of the front side guide plate of the hot continuous rolling wide strip coiler described in embodiment 1, the described side guide plate includes a parallel section and an inclined section, the parallel section of the side guide plate on the operation side and the parallel section of the side guide plate on the transmission side The distance between them is 1150mm-3400mm.

Embodiment 3

[0022] In the control device for the front side guide plate of the hot continuous rolling wide strip coiler described in embodiment 1 or embodiment 2, the hydraulic cylinder adopts a hydraulic cylinder with a maximum stroke of 1160mm.

[0023] Utilize the above-mentioned control device of the front side guide plate of the hot continuous rolling wide band steel coiler to carry out the control method of the front side guide plate of the hot continuous rolling wide band steel coiler: the method includes a position control process and a pressure control process, and the position control process Short-stroke action is set between the pressure control process, and the position control process is between the parallel section of the side guide plate on the operating side and the parallel section of the side guide plate on the transmission side before the strip steel enters the side guide plate. The distance is set to 3330mm. In the pressure control process, when the thickness of the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com