Methods to improve the mechanical stability of superhydrophobic wood

A mechanically stable, super-hydrophobic technology, applied in the direction of impregnated wood, wood impregnation, wood processing appliances, etc., can solve the problems of short service life, poor surface mechanical stability and durability, and poor hydrophobic surface mechanical properties. , to achieve the effect of short production cycle, improved mechanical stability and excellent hydrophobic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

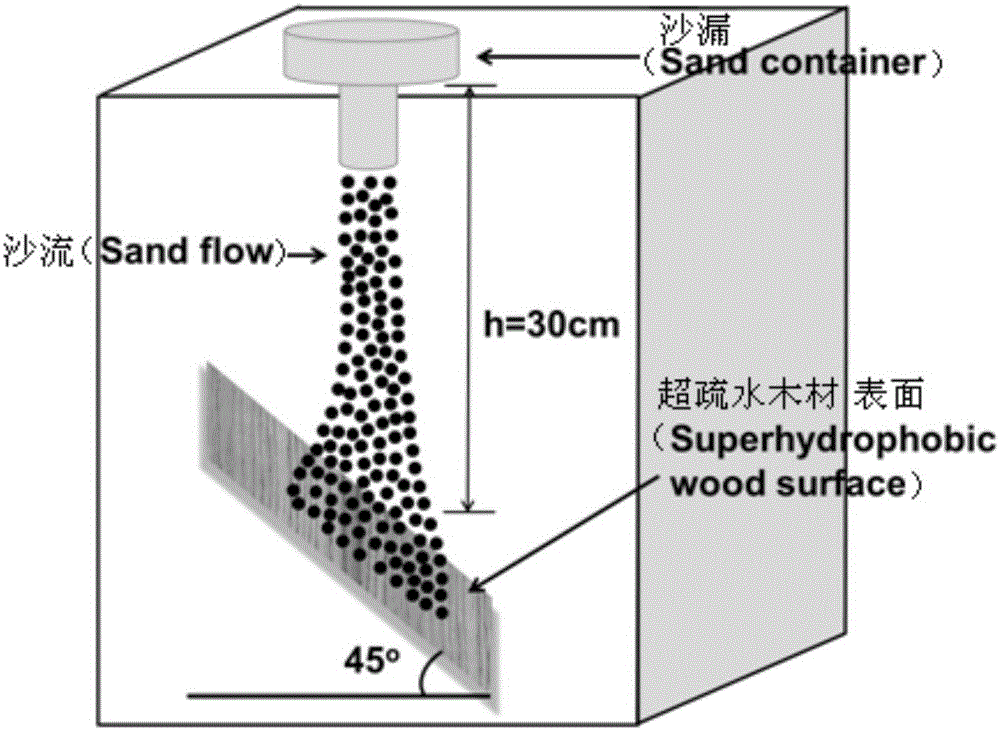

[0029] Embodiment 1: The method for improving the mechanical stability of superhydrophobic wood in this embodiment is achieved by the following steps:

[0030] Step 1, the wood is washed with deionized water, absolute ethanol, and deionized water in sequence;

[0031] Step 2, dissolving the epoxy resin in acetone to obtain an epoxy resin solution;

[0032] Step 3, soak the wood treated in step 1 in the epoxy resin solution obtained in step 2, and then dry at room temperature;

[0033] Step 4, modifying submicron silica with KH550 silane coupling agent, and then dispersing in deionized water to obtain modified silica liquid;

[0034] Step 5, soaking the wood treated in step 3 in the modified silica solution obtained in step 4, and drying at room temperature;

[0035] Step 6: Dissolve octadecyltrichlorosilane (OTS) in absolute ethanol to obtain an OTS ethanol solution, then soak the wood treated in step 4 in the OTS ethanol solution, and then dry it, thus realizing the super-h...

specific Embodiment approach 2

[0039] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the mass concentration of the epoxy resin solution described in step 2 is 1% to 5%. Other steps and parameters are the same as in the first embodiment.

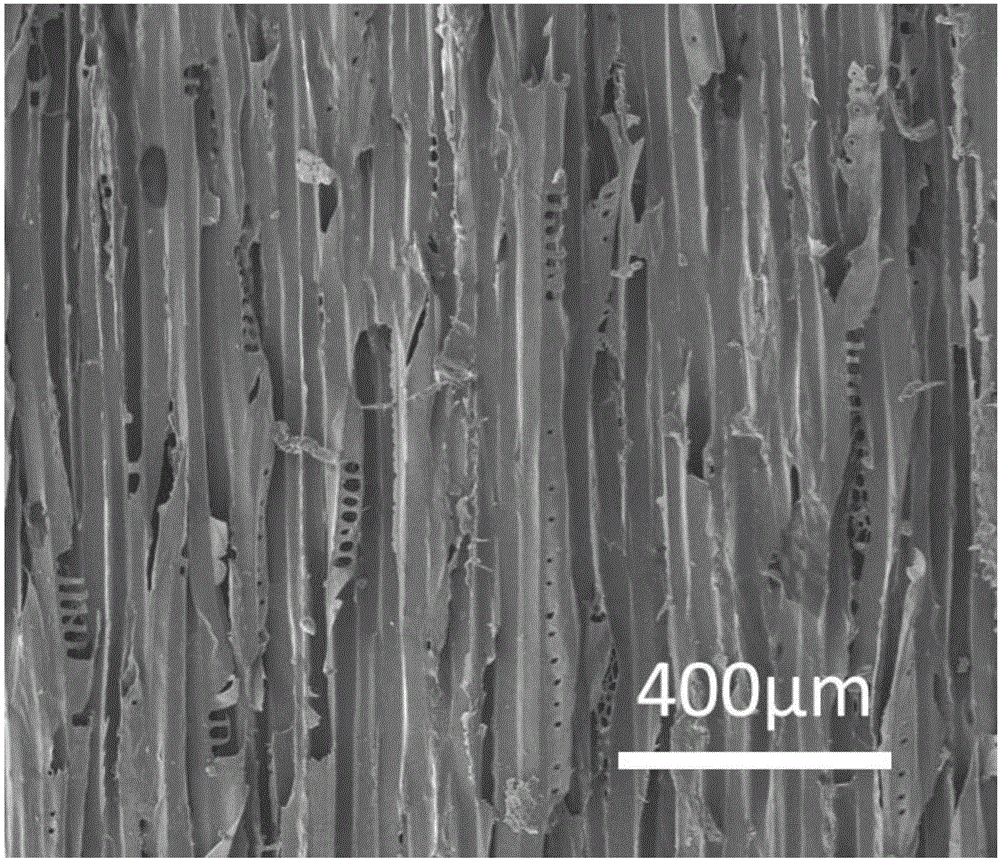

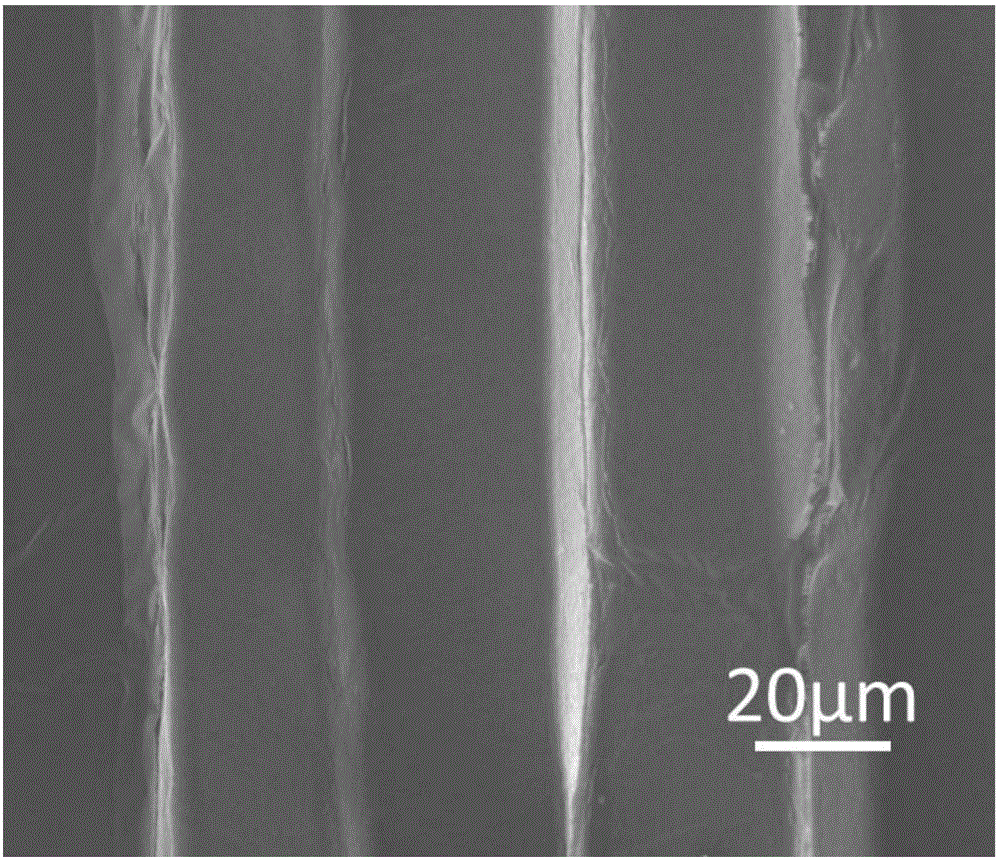

[0040] The contact angle between the superhydrophobic wood and water is greater than 150° and the rolling angle is less than 10° after the method of this embodiment; and a stable rough structure-micro-nano secondary structure is formed on the surface of the wood, so that the mechanical stability of the superhydrophobic wood is greatly improved. improve.

specific Embodiment approach 3

[0041] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the soaking time in step 3 is 0.5h-1.5h, and the drying time is 0.5h-1h. Other steps and parameters are the same as in the first or second embodiment.

[0042]The contact angle between the superhydrophobic wood and water is greater than 150° and the rolling angle is less than 10° after the method of this embodiment; and a stable rough structure-micro-nano secondary structure is formed on the surface of the wood, so that the mechanical stability of the superhydrophobic wood is greatly improved. improve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com