Connecting structure and connecting method of automobile parts

A technology for auto parts and connection structures, which is applied in the field of connection structures and connections of auto parts, which can solve problems such as high welding costs, difficulty in ensuring the strength of riveting and bonding connections, and complicated connection processes, so as to reduce production costs and shorten product production The effect of periodic, simple and stable connection structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, characteristics and methods of the automobile steel-aluminum connection structure and its connection method of the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. Its effect is described in detail below.

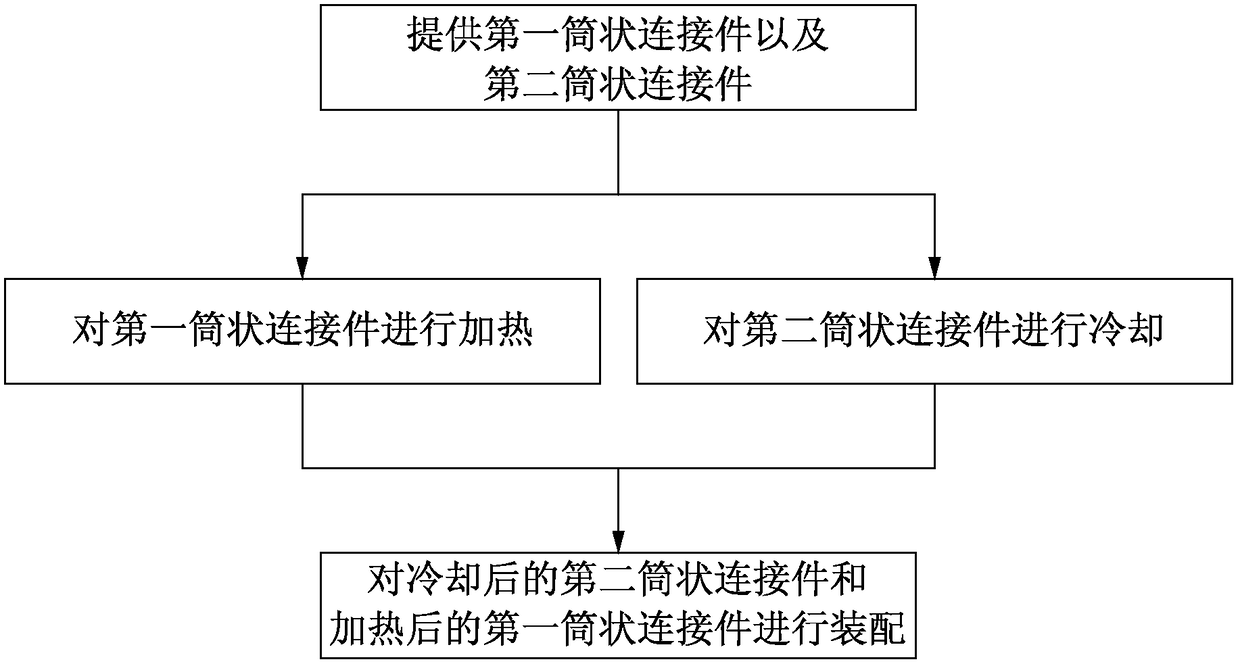

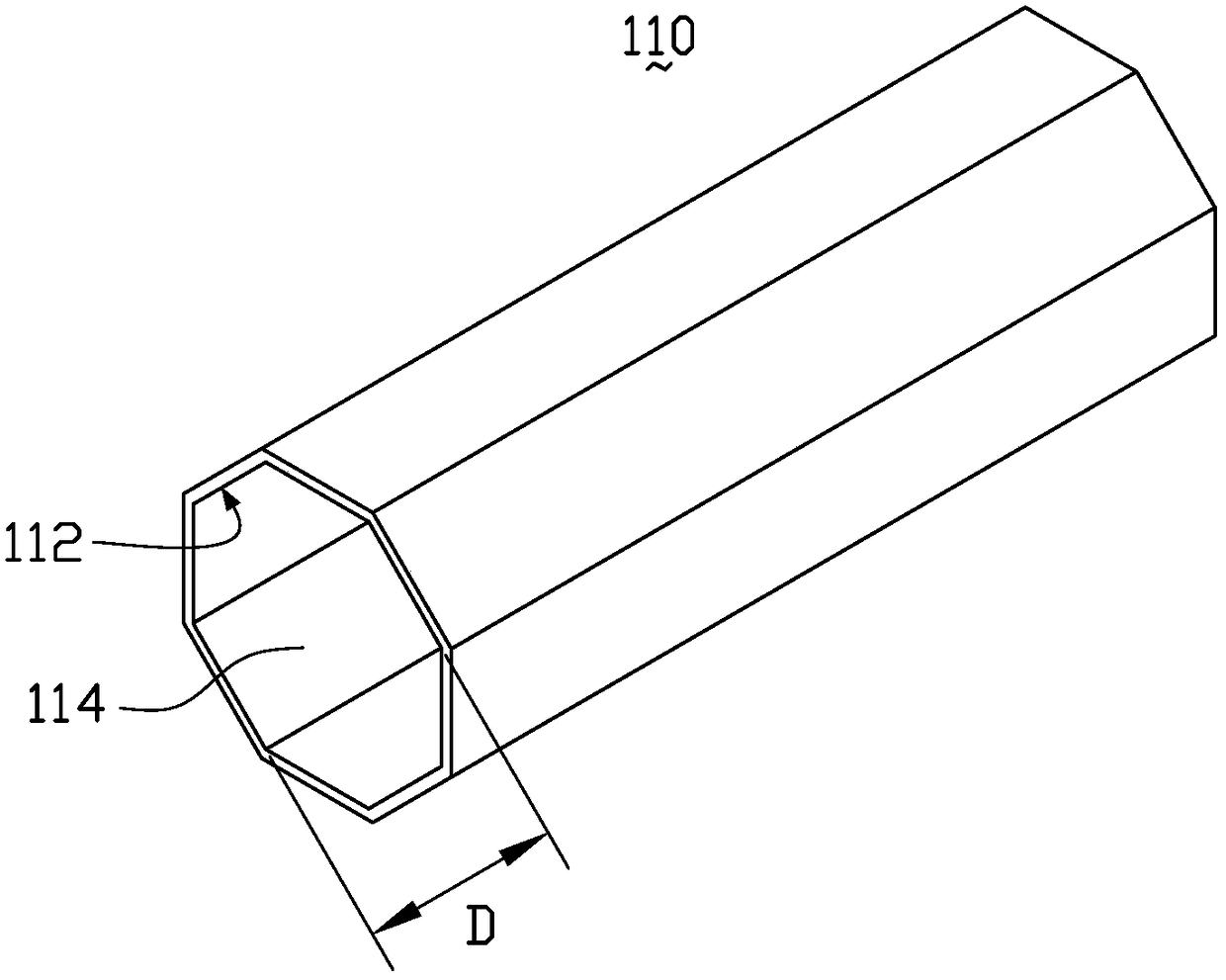

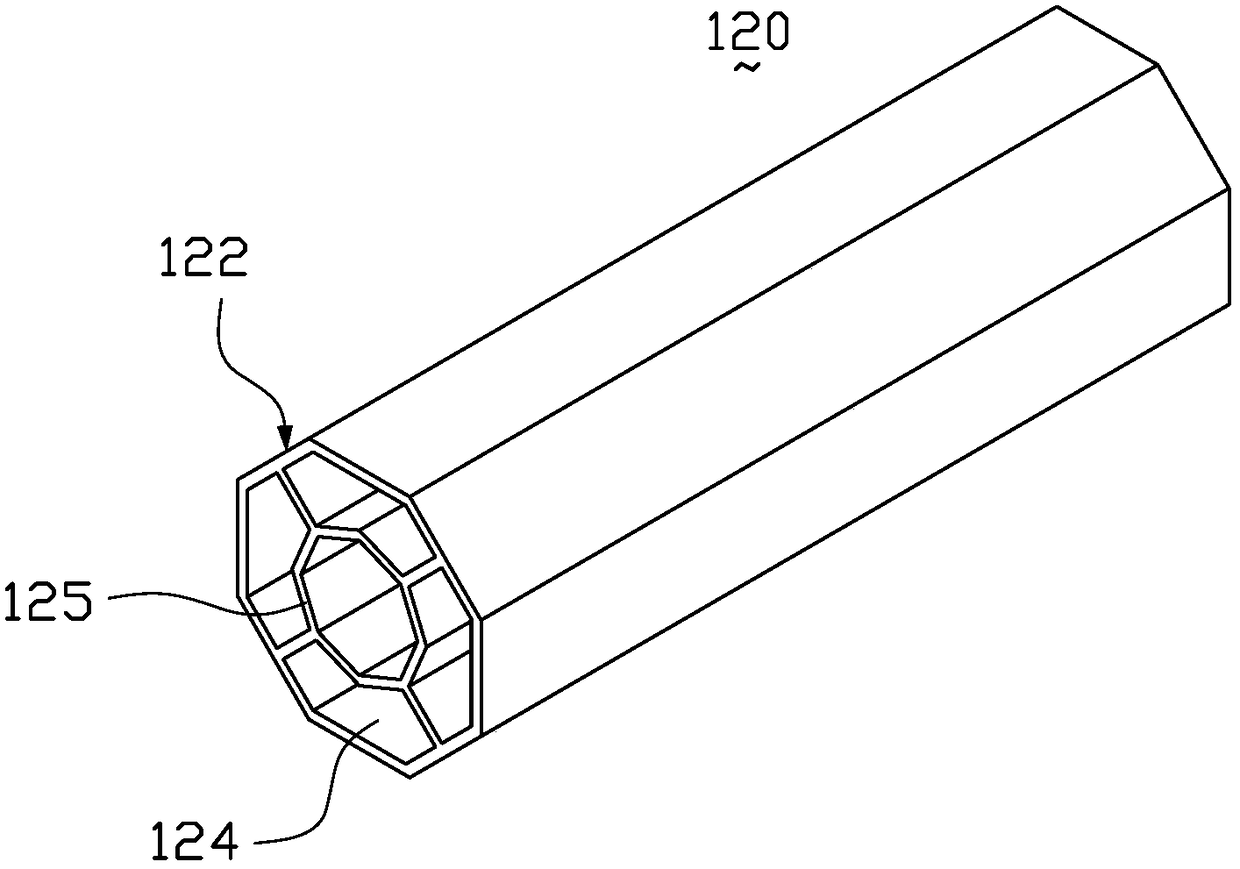

[0018] figure 1 It is a block flow diagram of a method for connecting automobile parts according to an embodiment of the present invention. The connecting method of this embodiment is suitable for connecting cylindrical connecting pieces to form a sleeve-shaped connecting structure. Please refer to figure 1 , firstly, the first cylindrical connector and the second cylindrical connector to be connected are provided. figure 2 It is a structural schematic diagram of the first tubular connector of the automobile parts connecting s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com