Treatment method and recycling method of livestock and poultry breeding wastewater and biogas slurry

A technology for the treatment of livestock and poultry breeding wastewater and biogas slurry, which is applied in the field of harmless treatment and recycling of up-to-standard discharge water, which can solve the problems of waste of water resources, failure to meet the requirements of reuse for flushing fences, and large amount of bacteria.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

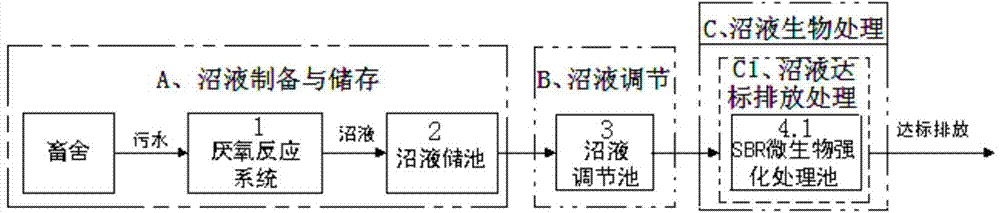

[0035] Example 1: As shown in the figure, is the basic embodiment of the present invention. A method for treating livestock and poultry breeding wastewater and biogas slurry, comprising the steps of:

[0036] A. Preparation and storage of biogas slurry: the livestock and poultry house sewage is treated by the anaerobic reaction system 1 by conventional methods and then input into the biogas slurry storage tank 2 for storage;

[0037] B. Biogas slurry adjustment: transport the biogas slurry in the biogas slurry storage tank 2 to the biogas slurry adjustment tank 3 for sedimentation and separation and / or remove suspended matter in the biogas slurry;

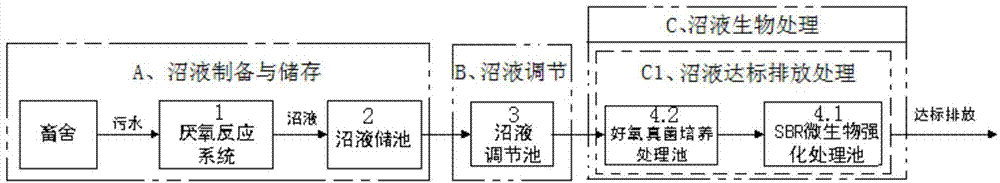

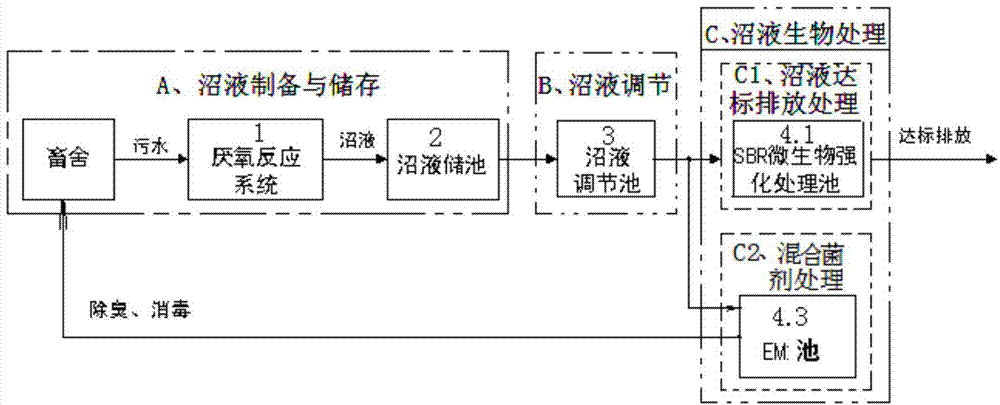

[0038] C. Biological treatment of biogas slurry: output the regulated biogas slurry in the biogas slurry adjustment pond 3 to carry out the biogas slurry up-to-standard discharge treatment in step C1 (such as figure 1 , 2 ), or output one way to carry out the biogas slurry up-to-standard discharge treatment of the step C1, and ...

Embodiment 2

[0040] Example 2: Such as figure 1 Shown is a preferred embodiment. On the basis of Example 1, it is specific: the biogas slurry in the step C1 reaches the standard discharge treatment is: the biogas slurry regulated by the biogas slurry adjustment pond 3 is transferred to the SBR microbial enhanced treatment pond 4.1 for intensive treatment, and the biogas slurry is strengthened in the pond. The treatment is to eliminate biogas slurry pollutants and cultivate activated sludge including microbial inoculum; the inoculum used is mainly a combination of at least two kinds of Bacillus subtilis, nitrifying bacteria, denitrifying bacteria and lactic acid bacteria; inoculum The dosage is connected to the treatment pool according to the inoculation amount of 1%-10%; the bacterial content of the bacterial agent is 1×10 6 -1×10 12 After cfu / g, there is no need for long-term bacterial injection, only a small amount of regular supplementation is required;

[0041] In this embodiment,...

Embodiment 3

[0042] Example 3: is yet another further preferred embodiment. The difference from Example 2 is: during the enhanced treatment in SBR microbial enhanced treatment tank 4.1, the temperature of the liquid in the SBR microbial enhanced treatment tank is controlled at 15-35°C, and the residence time is 2-3 days. The treatment process includes a liquid intake time of 0.5 hours , the aeration time is 4.5 hours, the sedimentation time is 2.5 hours, and the discharge time is 0.5 hours; the treatment process runs 3 times a day, and the liquid dissolved oxygen in the pool is controlled at 2-5mg / L during aeration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com