Preparation method of modified polytrifluorochloroethylene material

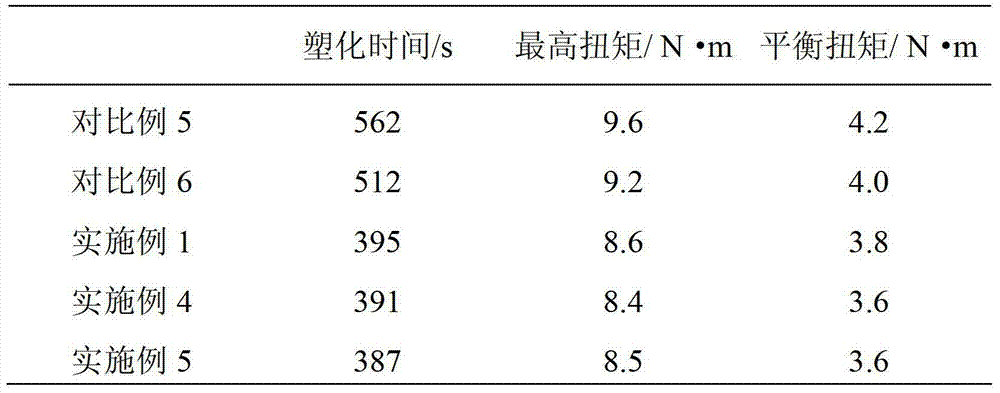

A polychlorotrifluoroethylene, modified technology, applied in the field of polymer compound preparation, can solve the problems of PCTFE product performance degradation, limited application range and production capacity, injection molding processing difficulties, etc., to achieve product performance improvement, chlorine free The effect of reducing the base activity and shortening the melting and plasticizing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

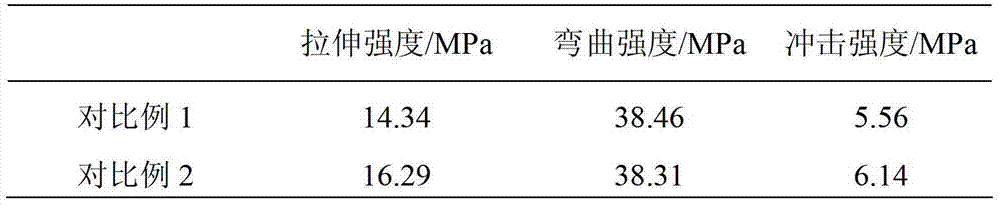

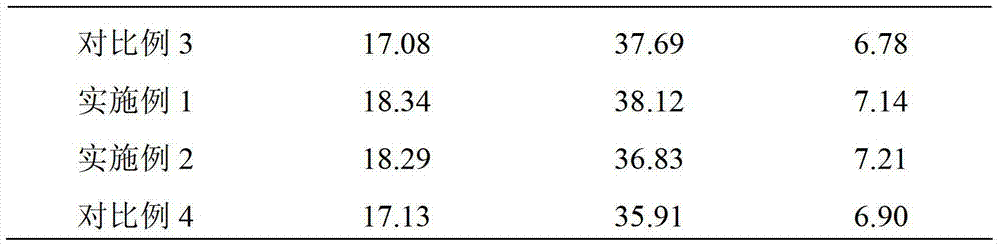

Examples

Embodiment 1

[0017] PCTFE600g, rare earth composite stabilizer 36g, N,N'-bis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl]hydrazine 6g, acrylate 6g, stearic acid 6g, PE 12g of wax is mixed, and after mixing, it is added to a mixer for melting and plasticization. The mixing processing temperature is 265°C and the rotation speed is 30r / min; the product made by the mixing machine is added to an injection molding machine for injection processing. The processing temperature of the injection molding machine is 260 ℃, the mold temperature is 100 ℃, injection molded standard splines; referring to the above tensile strength standard, bending strength standard, impact strength standard and Vicat heat distortion temperature standard, the performance test and result characterization of the sample are carried out.

Embodiment 2

[0019] Repeat the same steps as described in Example 1, but in Example 2, raw material PCTFE, rare earth composite stabilizer, N, N'-bis[β-(3,5-di-tert-butyl-4-hydroxyphenyl ) Propionyl]hydrazine, acrylate, stearic acid and PE wax are respectively 600g, 48g, 6g, 6g, 6g and 12g.

Embodiment 3

[0021] Example 1 was repeated in the same steps as described, but the kneading processing temperature in Example 3 was 255°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com