Hanger for electroplating bridge rectifier frame

A technology of rectifier bridge stack and frame, applied in the direction of electrolysis process and electrolysis components, can solve the problems of easy deformation of hooks, slow operation efficiency, rough workpiece coating, etc., to avoid tip discharge phenomenon, high operation efficiency, and good electroplating effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

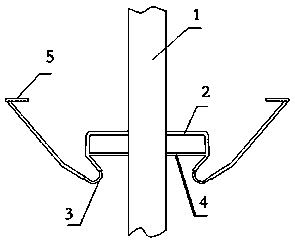

[0015] Such as figure 1 As shown, a hanger for rectifier bridge stack frame electroplating of the present invention includes several vertical

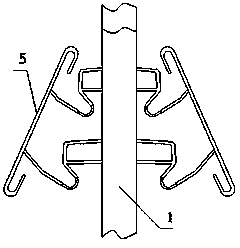

[0016] Straight and side-by-side struts 1, these struts 1 are connected as a whole through cross bars. A plurality of brackets 2 extending radially outward are arranged side by side on opposite sides of each support rod 1 , and a conductive plated component resting portion 3 bent obliquely downward into a U-shape is arranged in the middle of the bracket 2 . Except for the shelving part 3 of the plated part, an insulating layer is provided on the outer surface of other parts. Below the root of the bracket 2, there is a reinforcing rod 4 connected between the pole 1 and the plated piece resting part 3, which serves to reinforce the bracket 2 and prevent the bracket 2 from being deformed. Such as figure 2 As shown, a blocking rod 5 is transversely connected between the ends of the bracket 2 on two adjacent poles 1 , the two ends of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com