Track acoustic board structure

A technology of sound-absorbing panels and tracks, applied in tracks, roads, buildings, etc., to reduce impact, increase sound absorption, and relieve sound wave pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

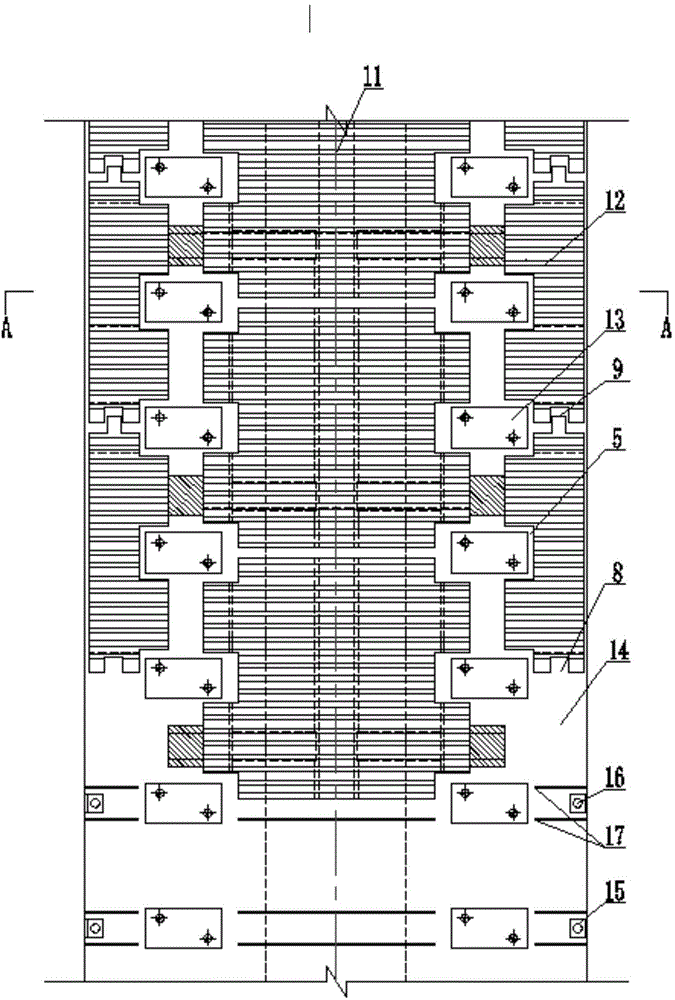

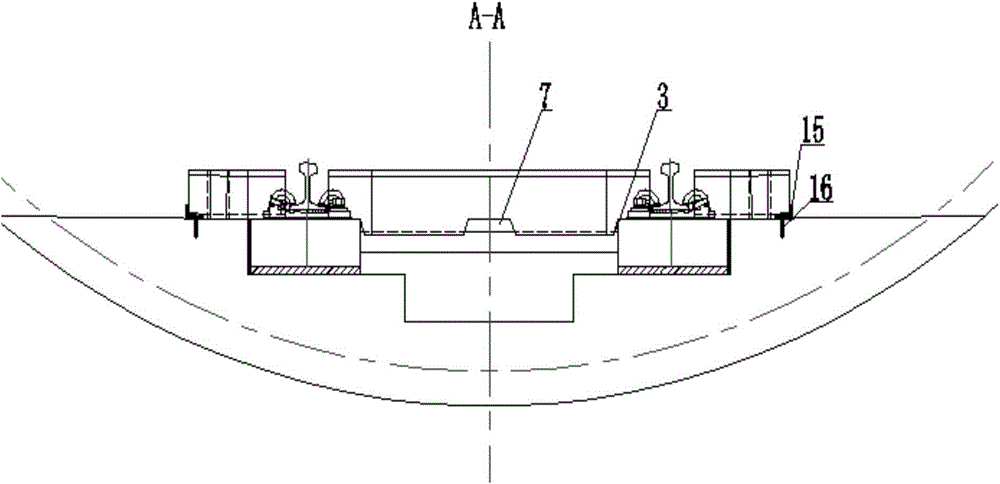

[0031] see Figure 1-2 , shows a specific schematic diagram of the track sound-absorbing panel structure of the present invention installed on the track.

[0032] The rail sound-absorbing panel structure includes a central panel body 11 located between the rails on both sides and side panel bodies 12 located on both sides of the rails.

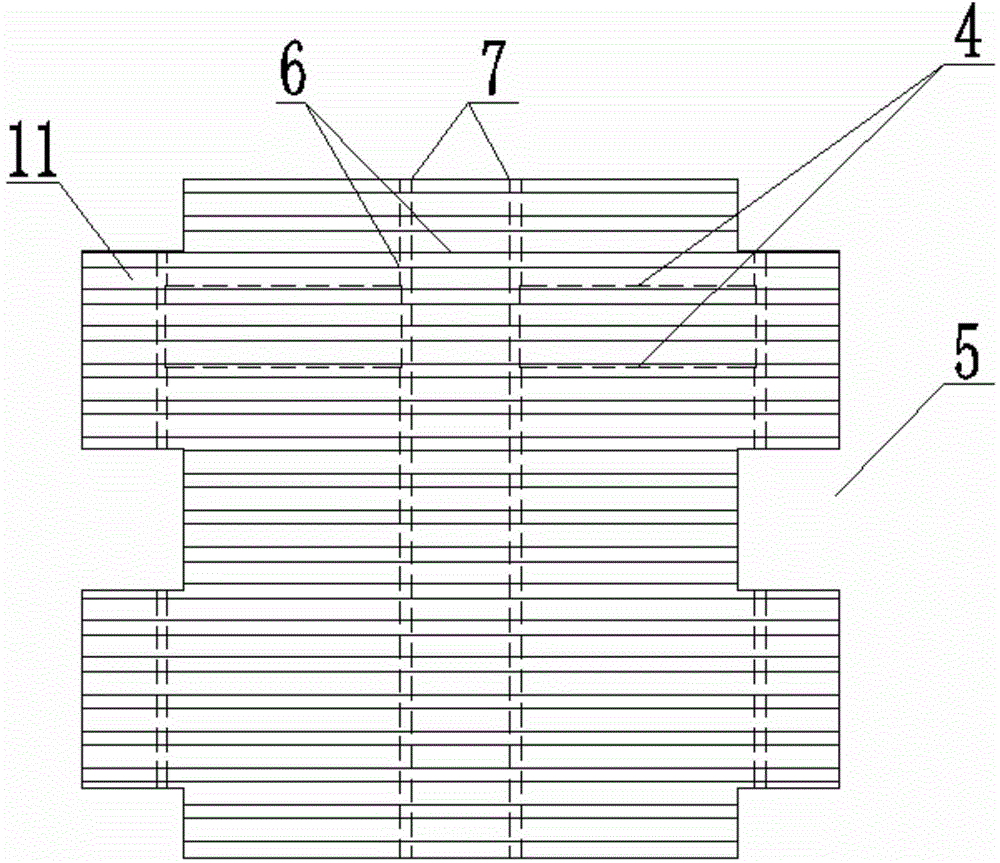

[0033] see Figure 3-5 , shows the central block plate body 11 of the present invention, the central block plate body 11 is a honeycomb structure plate body, and the left and right ends of the central block plate body 11 are provided with sleeper recesses 3 matching the sleepers, and the central block plate body The middle part of the lower surface of the body 11 is provided with a longitudinal drain groove 7, and the drain groove 7 corresponds to the position of the drain. The corners are provided with recesses, and the recesses of the bearing platform 5 and the four corners correspond to the bearing platform 13 of the track. The lower surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com