Low-cost ecological ceramic material with various sound-absorbing structures and its preparation method

An ecological ceramic and low-cost technology, applied in the field of preparation of low-cost ecological ceramic materials, can solve the problems of single function, single sound-absorbing structure, high raw material cost, etc., achieve high mechanical strength, improve sound-absorbing effect, and increase open porosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] A method for preparing a low-cost ecological ceramic material with multiple sound-absorbing structures of the present invention, the specific operation process includes the following steps:

[0045] Step 1, weighing raw materials according to the following mass percentages: 22% to 27% of fly ash, 13% to 18% of coal gangue, 8% to 12% of red mud, 40% to 45% of shale, 5% to 10% of feldspar %, foaming agent 0.2%~2%, binder 0.5%~3%, pore forming agent 5%~10%, surfactant 0%~1%, spare;

[0046] Foaming agent is calcium carbonate, calcium sulfate and silicon carbide any one or several compositions according to arbitrary proportion;

[0047] The binding agent is one or both of sodium carboxymethyl cellulose and xanthan gum in any proportion;

[0048] The pore forming agent is any one of polystyrene balls, spherical plastic particles, spherical activated carbon and coal powder or a combination of several in any proportion;

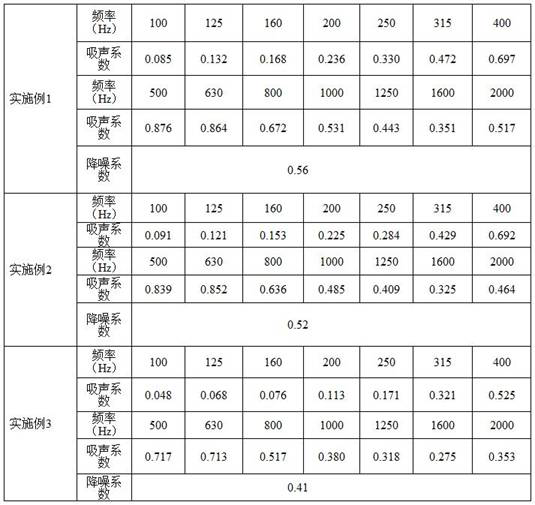

Embodiment 1

[0057] A method for preparing a low-cost ecological ceramic material with multiple sound-absorbing structures, the specific operation process includes the following steps:

[0058] Step 1, weigh raw materials according to the following mass percentages: 25% fly ash, 15% coal gangue, 10% red mud, 43% shale, 7% feldspar, 0.5% silicon carbide, 2% xanthan gum, polystyrene Vinyl ball (diameter 1~2mm) 8%, coal powder (40~60 mesh) 4% and polyvinyl alcohol 1% spare;

[0059] Wherein, the mass percent of each component in the fly ash is as follows: SiO 2 48%, Al 2 o 3 27%, Fe 2 o 3 8%, TiO 2 1%, CaO 8%, MgO 1%, K 2 O is 1%, Na 2 O is 0.3%;

[0060] The mass percent of each component in coal gangue is as follows: SiO 2 43%, Al 2 o 3 27%, Fe 2 o 3 5%, TiO 2 1%, CaO 1%, MgO 1%, K 2 O is 1%, Na 2 O is 0.3%;

[0061] The mass percent of each component in the red mud is as follows: SiO 2 30%, Al 2 o 3 27%, Fe 2 o 3 10%, CaO 12%, Na 2 O is 7%.

[0062] The mass percent...

Embodiment 2

[0072] A method for preparing a low-cost ecological ceramic material with multiple sound-absorbing structures, the specific operation process includes the following steps:

[0073] Step 1, weigh raw materials according to the following mass percentages: 22% fly ash, 14% coal gangue, 8% red mud, 45% shale, 5% feldspar, 1% mixture of silicon carbide and calcium carbonate, carboxymethyl Sodium cellulose 1%, spherical plastic particles (diameter 2~3mm) 8%; coal powder (40~60 mesh) 4% and polyvinyl alcohol 0.3% spare;

[0074] Wherein, the mass percent of each component in the fly ash is as follows: SiO 2 45%, Al 2 o 3 25%, Fe 2 o 3 5%, TiO 2 0.5%, CaO 5%, MgO 0.5%, K 2 O is 0.5%, Na 2 O is 0.1%;

[0075] The mass percent of each component in coal gangue is as follows: SiO 2 40%, Al 2 o 3 25%, Fe 2 o 3 3%, TiO 2 0.5%, CaO 0.5%, MgO 0.5%, K 2 O is 0.5%, Na 2 O is 0.1%;

[0076] The mass percent of each component in the red mud is as follows: SiO 2 20%, Al 2o 3 25...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com