A kind of preparation method of low-voltage high-energy sic semiconductor nozzle material

A semiconductor and high-energy technology, applied in the field of preparation of low-voltage and high-energy SiC semiconductor nozzle materials, can solve the problems of thermal shock resistance cracking, poor high temperature resistance, high spark energy, etc., to improve impact resistance, easy to operate, prevent The effect of surface area carbon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

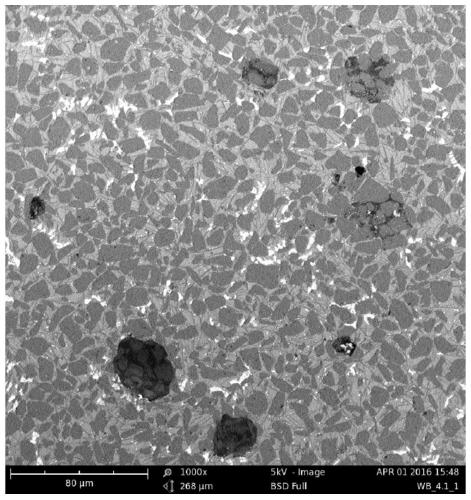

Image

Examples

Embodiment Construction

[0022] Now, the present invention will be further described in conjunction with the embodiments and accompanying drawings, but the implementation of the present invention is not limited thereto.

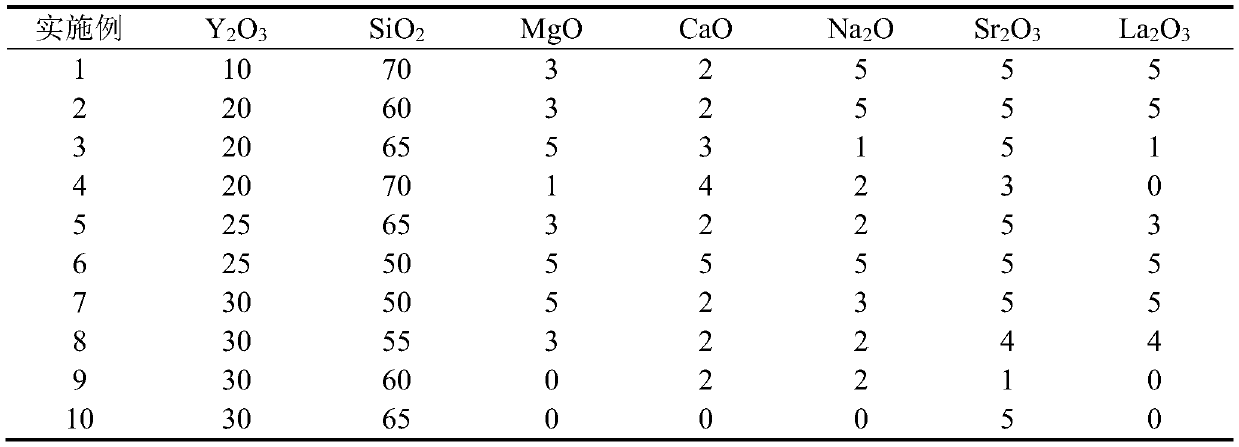

[0023] 1) Weigh the composite oxide powder raw material forming the glass system according to the formula in Table 1, wherein K 2 O, Na 2 O was introduced in the form of Ca respectively 2 CO 3 , Na 2 CO 3 , The grade of raw materials is experimental grade analytical grade, mixed evenly by ball milling, the ball milling medium is absolute ethanol, and the ratio of balls, materials, and medium is 2:1:1. Put the mixture into a crucible, sinter in an air furnace with the process parameters in Table 2, the heating rate is 50°C / min, and cool with the furnace to form a glass system composite oxide powder;

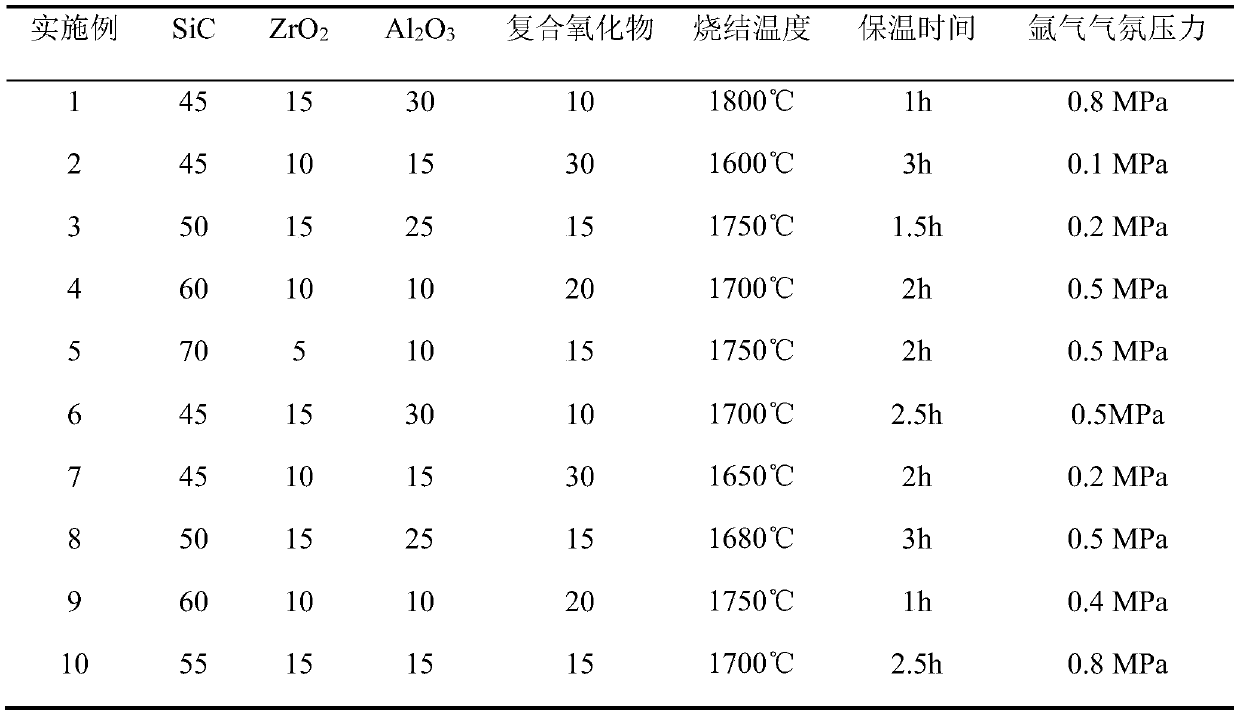

[0024] 2) According to the formula ingredients in Table 2, the grade of raw material is experimental grade analytical grade, mixed evenly by ball milling, the ball milling medium is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com