Coupling resonance sound-absorbing device by utilizing combination of lumen coupling and tube bundle perforation plate

A technology of coupling resonance and sound-absorbing devices, applied in the direction of sound-generating equipment, instruments, etc., can solve the problem of insufficient low-frequency sound absorption, and achieve the effect of consuming sound energy and increasing sound quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In this embodiment, two coupling resonance sound-absorbing devices of the present invention are produced.

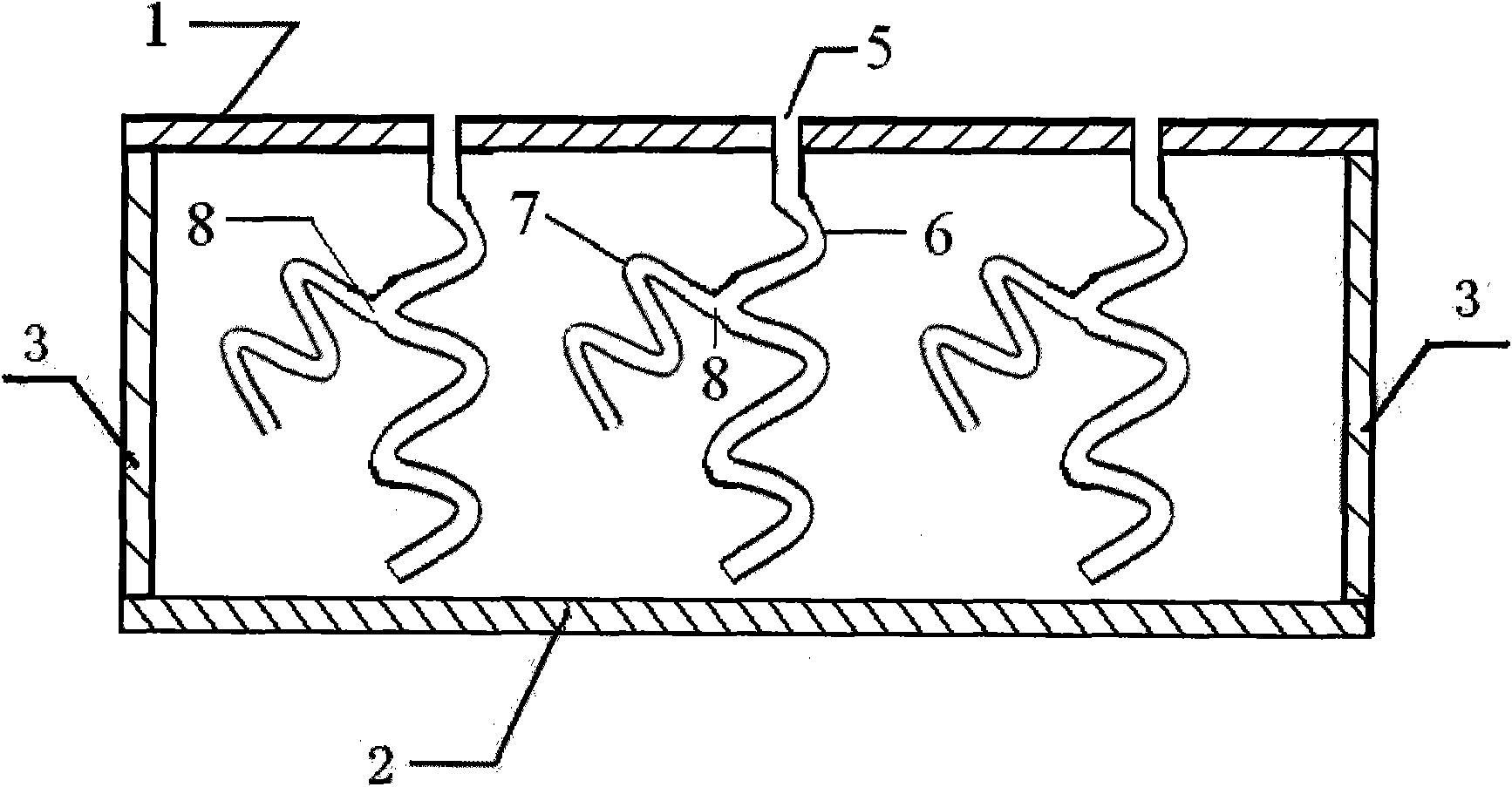

[0039] refer to figure 1 The first one is the resonant sound-absorbing device of the present invention with a first side branch tube bundle 7, which is a closed space composed of a perforated plate 1 made of stainless steel, a back plate 2 made of stainless steel and a side plate 3 made of stainless steel. cavity, the depth D of the closed cavity is 120mm, the perforated plate 1 is a circular stainless steel plate with a diameter of 29mm, and the thickness is 0.8mm, the perforated plate 1 is provided with a hole 5, the diameter of the hole 5 is 1.6mm, and the perforation rate of the hole 5 is The hole 5 on the perforated plate 1 is arranged in a regular square arrangement; 21 rubber-made main tube bundles 6 are installed on the holes 5 on the perforated plate 1 through the transition joint 4, and an open end of the main tube bundle 6 is 6.4%. Connected to the per...

Embodiment 2

[0046] In this embodiment, two coupled resonant sound-absorbing devices that utilize tube cavity coupling and tube bundle perforated plates are fabricated.

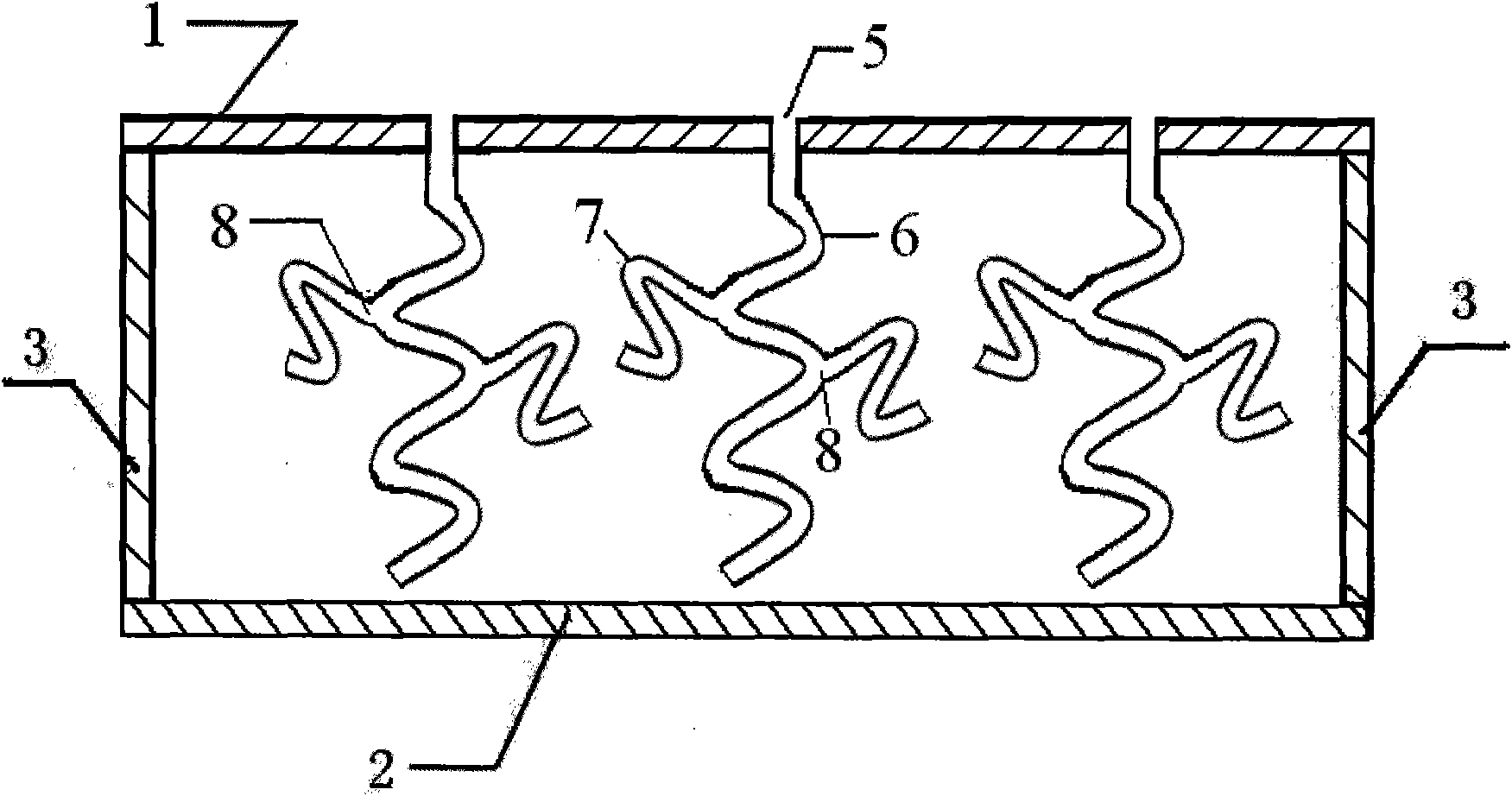

[0047] The structure of the first resonant sound-absorbing device of the present invention is the same as that of the second coupled resonant sound-absorbing device of the present invention in Embodiment 1, the difference is that 49 main tube bundles 6 made of rubber are installed in the holes 5 on the perforated plate 1 superior.

[0048] The difference also lies in: a closed cavity composed of a perforated plate 1 made of stainless steel, a back plate 2 made of plexiglass and a side plate 3 made of plexiglass, the depth D of the closed cavity is 125mm, and the perforated plate 1 is the edge A square stainless steel plate with a length of 40 mm and a thickness of 0.8 mm. The perforation rate of the holes 5 on the perforated plate 1 is 6.2%. The arrangement of the holes 5 on the perforated plate 1 is a regular square arra...

Embodiment 3

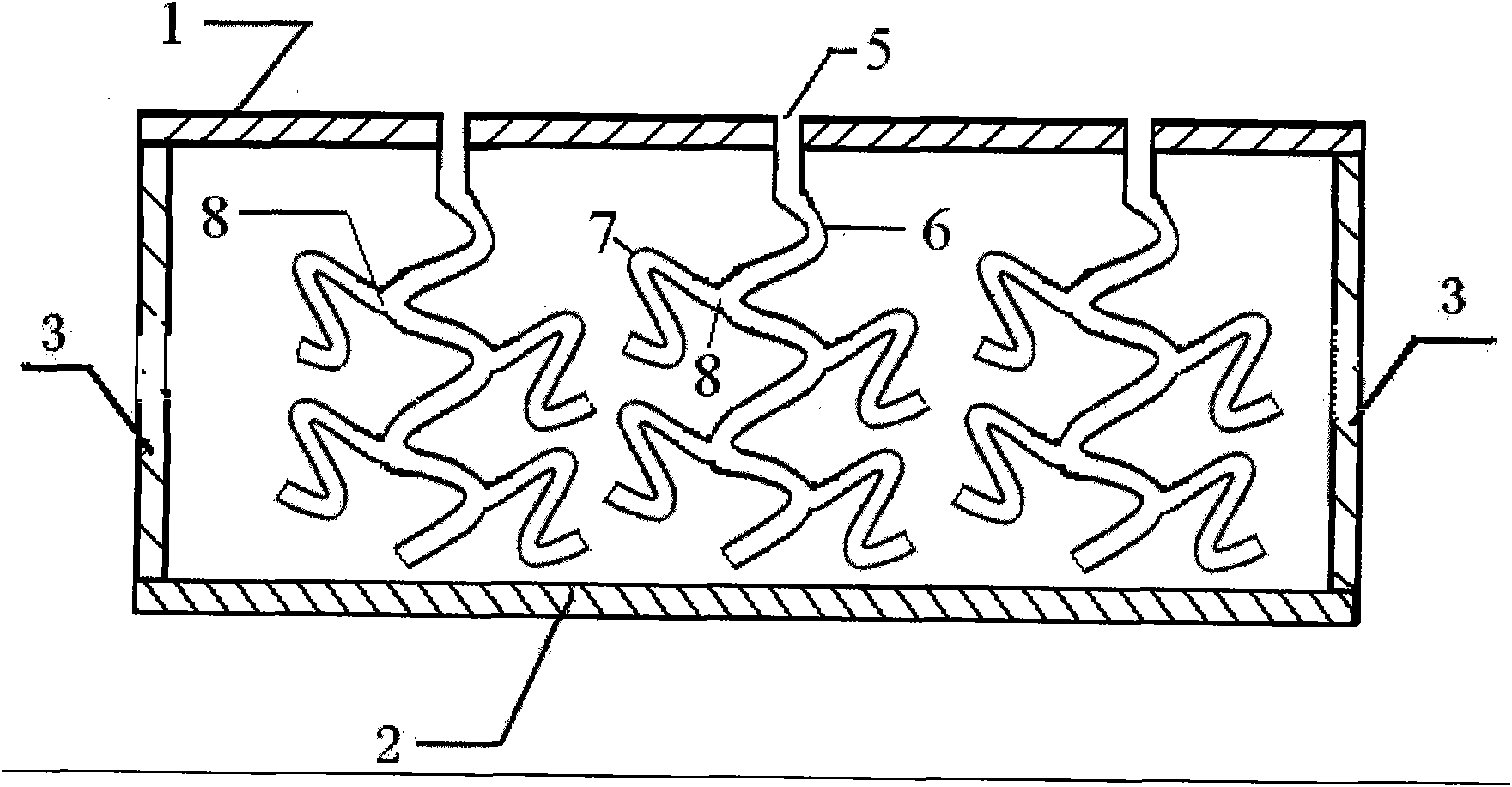

[0057] refer to Figure 4, In this embodiment, a coupled resonant sound-absorbing device that utilizes lumen coupling and a tube bundle perforated plate is fabricated. The closed cavity of the device is a closed cavity composed of a perforated plate 1, a back plate 2 and a side plate 3, wherein the perforated plate 1, the back plate 2 and the side plate 3 can be made of an iron plate or a copper plate with a thickness of 1.0mm , the depth D of the closed cavity can be 500mm, 800mm, 1000mm or 1500mm, the shape of the perforated plate 1 is a square with a side length of 40mm, the perforated plate 1 is provided with a hole 5, the diameter of the hole 5 is 3mm, and the hole 5 The perforation rate is 7.1%, and the holes 5 on the perforated plate 1 are arranged in a regular square arrangement; 16 main tube bundles 6 are installed on the holes 5 on the perforated plate 1 through the transition joint 4, wherein the main tube bundles can be glass tubes , plastic tube, rubber tube or c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com