Sound-absorbing room building floor structure

A sound-absorbing room and sound-absorbing panel technology, which is applied in building structure, construction, layered products, etc., can solve the problems of difficult volatilization and removal of water vapor and reduced sound-absorbing effect, achieve good sound-absorbing effect, avoid the reduction of sound-absorbing effect, and improve sound-absorbing effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

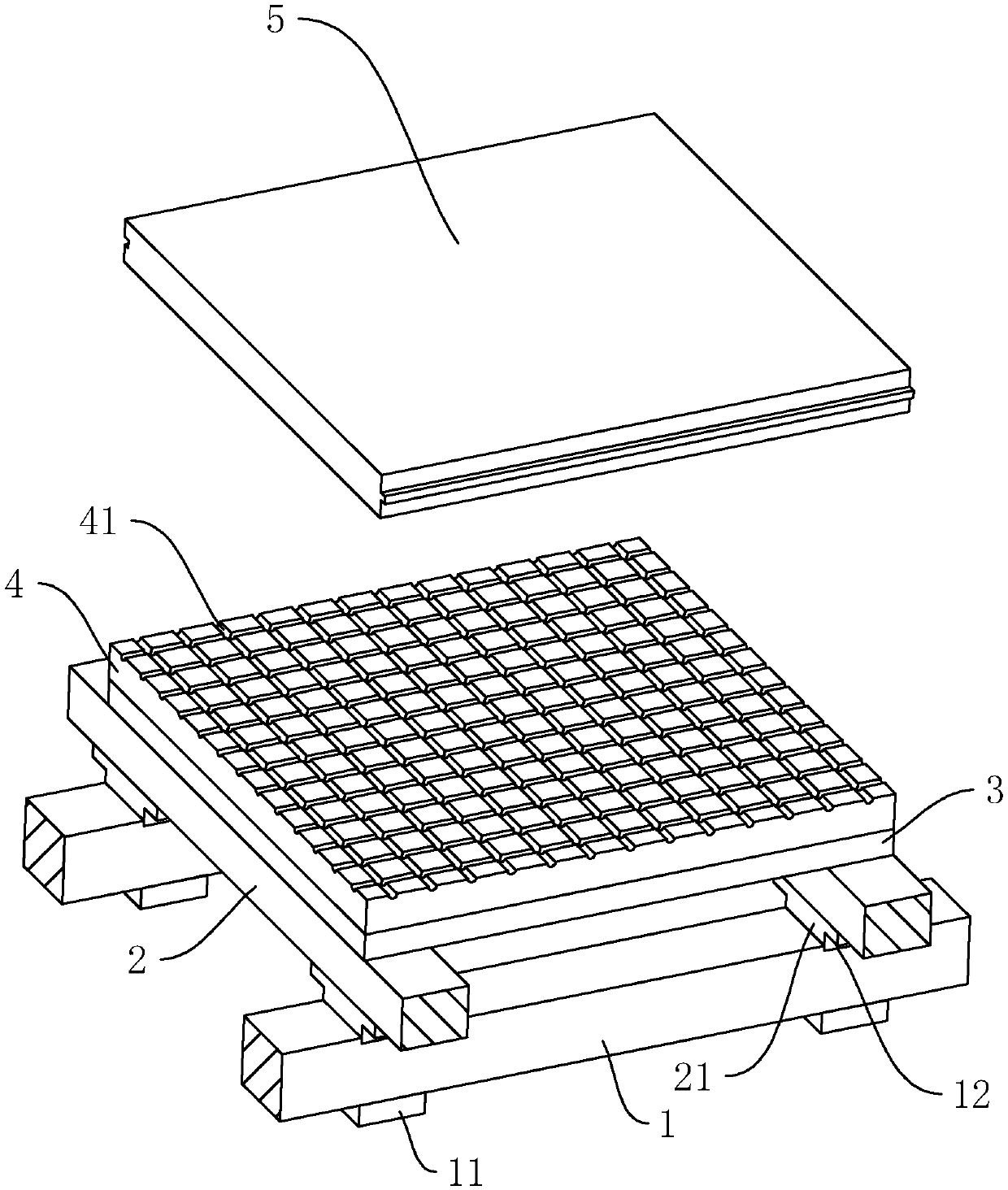

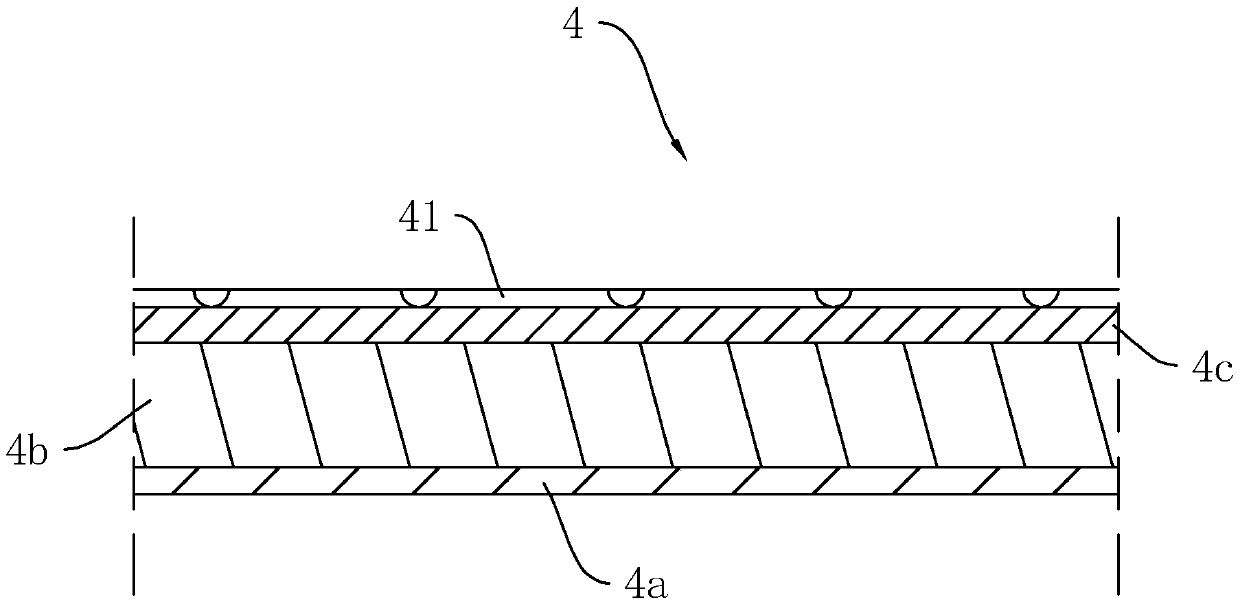

[0060] as attached figure 1 As shown, a sound-absorbing room building floor structure includes a lower keel 1, an upper keel 2, a lining board 3, a sound-absorbing layer 4b and a surface board 5. The lower keel 1 and the upper keel 2 are elongated, and the number of the two depends on the size of the indoor laying area. In the figure, the lower keel 1 and the upper keel 2 are interlaced to form a frame unit. The lower keels 1 are distributed at equal intervals, and at the same time, a plurality of pads 11 are arranged at intervals on the bottom surface of each lower keel 1 . The shape of the spacer 11 is determined according to the actual situation, and the spacer 11 is a cuboid shape equal to the width of the lower keel 1 here. Simultaneously, the upper surface of the lower keel 1 is equidistantly provided with sunken caulking grooves 12 along its length direction. The shape of the caulking grooves 12 can be determined according to the actual situation.

[0061] The upper ...

Embodiment 2

[0095] A floor structure for a sound-absorbing room, based on Embodiment 1A, the difference is that the sound-absorbing panel only includes a sound-absorbing layer, the upper surface of the sound-absorbing layer is in contact with the lower surface of the surface layer, and the lower surface of the sound-absorbing layer is in contact with the lower surface of the surface layer. The lower bottom surface of the liner is attached to each other.

Embodiment 3

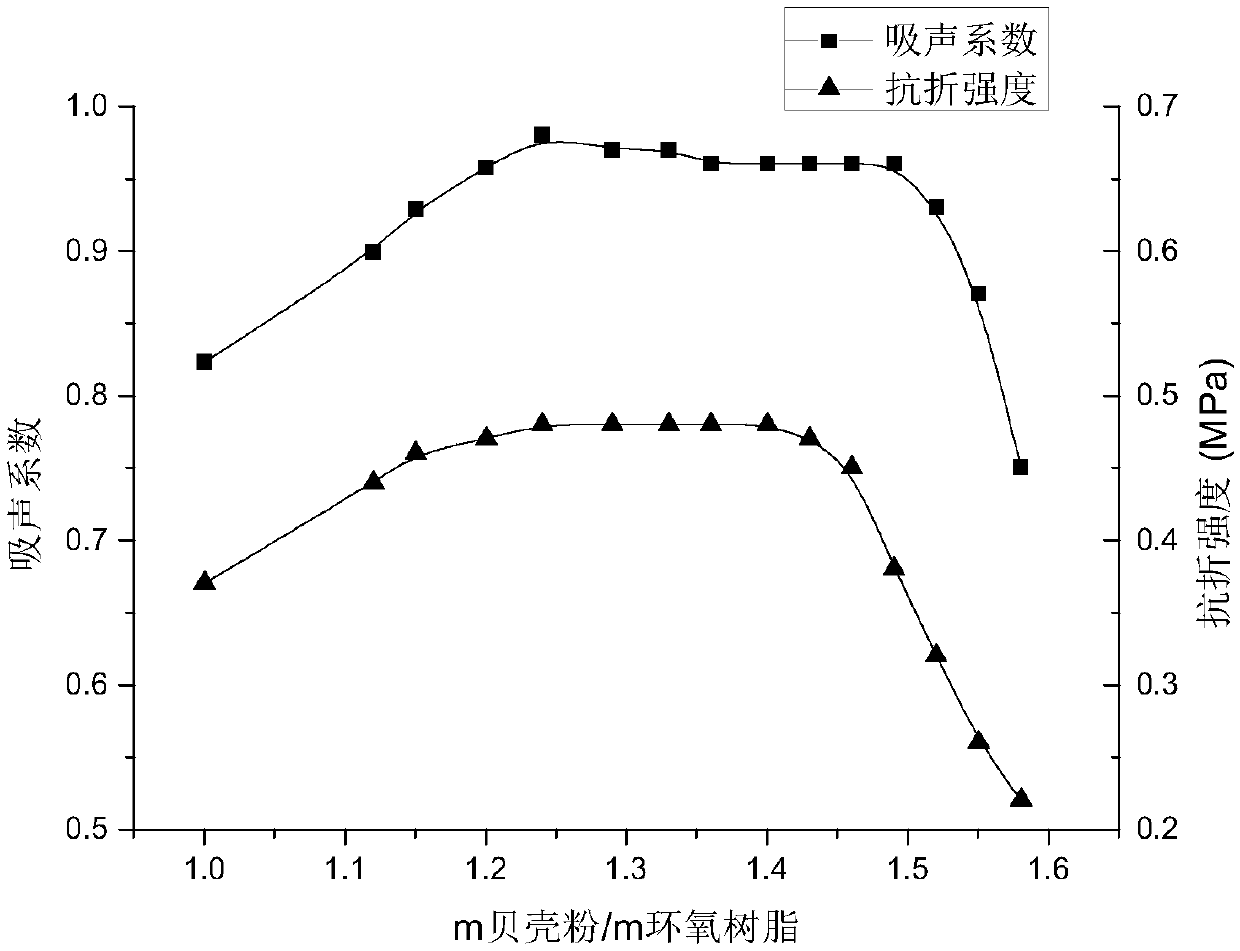

[0097] A sound-absorbing room building floor structure, based on the basis of Example 1A, the difference is that the shell powder is soaked in the eluate at low temperature and then filtered, and then the water with the same quality as the shell powder and ethanol with the same quality as the shell powder are used successively Wash and dry in an oven at 350°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com