Sound-absorbing device utilizing tube cavity coupled resonance and interbank coupled resonance

一种耦合共振、吸声装置的技术,应用在发声器械、仪器等方向,能够解决低频吸声不足等问题,达到拓宽吸声频带、提高高频吸声效果、增大吸声系数的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

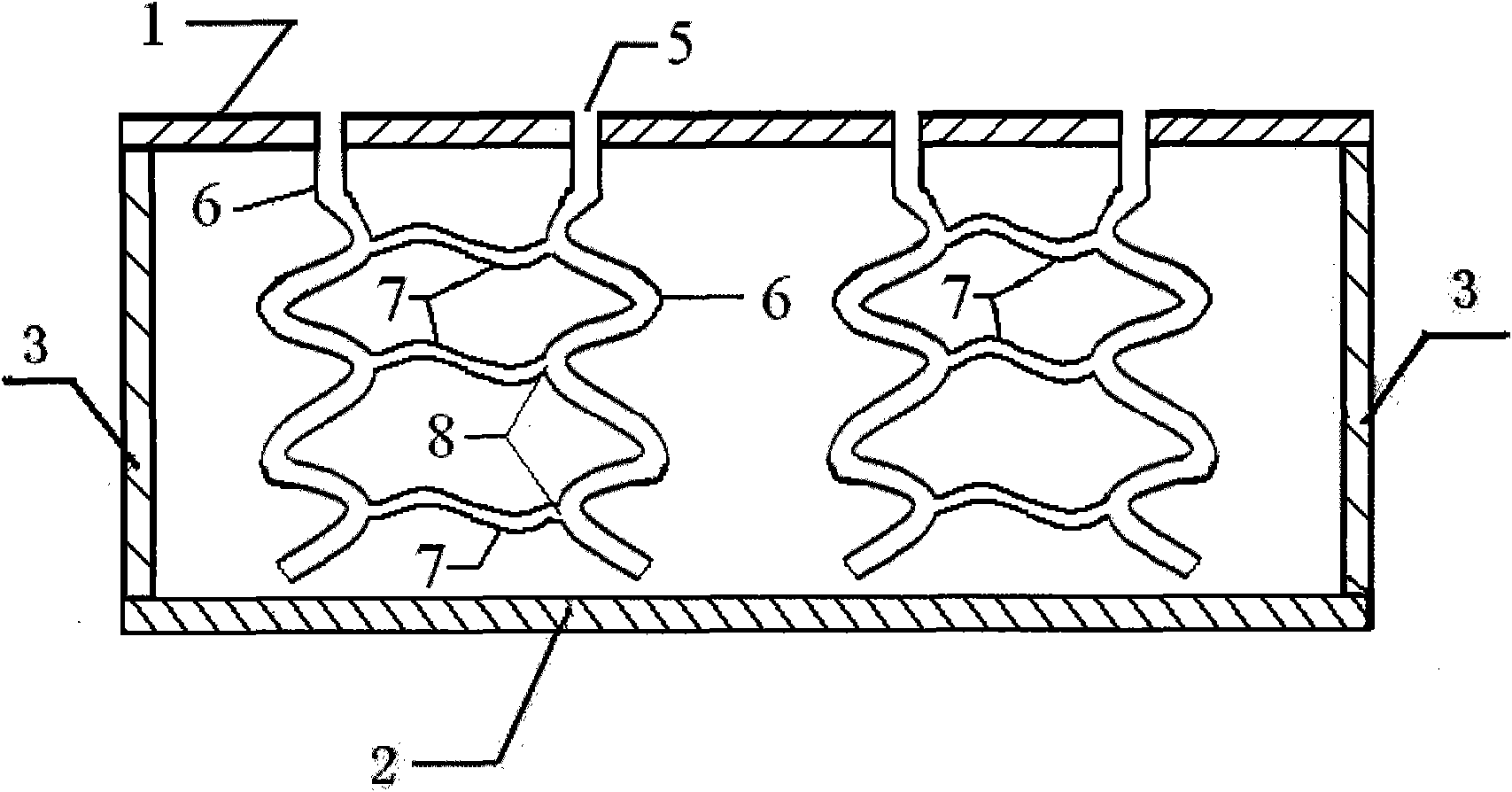

Embodiment 1

[0040] refer to figure 1 , In this embodiment, a sound absorbing device using coupling resonance between the lumen and coupling resonance between tube bundles is fabricated. The device is a closed cavity composed of a perforated plate 1 made of stainless steel, a back plate 2 made of plexiglass and a side plate 3 made of plexiglass, and the depth D of the closed cavity is 125mm. The perforated plate 1 is a square stainless steel plate with a side length of 40 mm and a thickness of 0.8 mm. Holes 5 are provided on the perforated plate 1, the diameter of the holes 5 is 1.6 mm, and the perforation rate of the holes 5 is 6.2%. The arrangement of the holes 5 on the perforated plate 1 is a regular square arrangement; The main tube bundle 6 is installed on the hole 5 on the perforated plate 1 . One open end of the main tube bundle 6 is connected to the perforated plate 1, and the other open end can be an opening or can close the opening. The number of the main tube bundles 6 is equ...

Embodiment 2

[0046] refer to figure 1 , In this embodiment, a sound absorbing device using coupling resonance between the lumen and coupling resonance between tube bundles is produced. The device is a closed cavity composed of a perforated plate 1 made of stainless steel, a back plate 2 made of plexiglass and a side plate 3 made of plexiglass, and the depth D of the closed cavity is 250 mm. The perforated plate 1 is a square stainless steel plate with a side length of 40 mm and a thickness of 0.8 mm. The perforated plate 1 is provided with holes 5 with a diameter of 1.6 mm and a perforation rate of 6.2%. The holes 5 on the perforated plate 1 are arranged in a regular square arrangement. 48 rubber-made main tube bundles 6 are installed on the holes 5 of the perforated plate 1 through the transition joint 4, and an opening end of the main tube bundle 6 is connected with the perforated plate 1, and the number of the main tube bundles 6 is equal to 5 holes. The length of the main tube bundle...

Embodiment 3

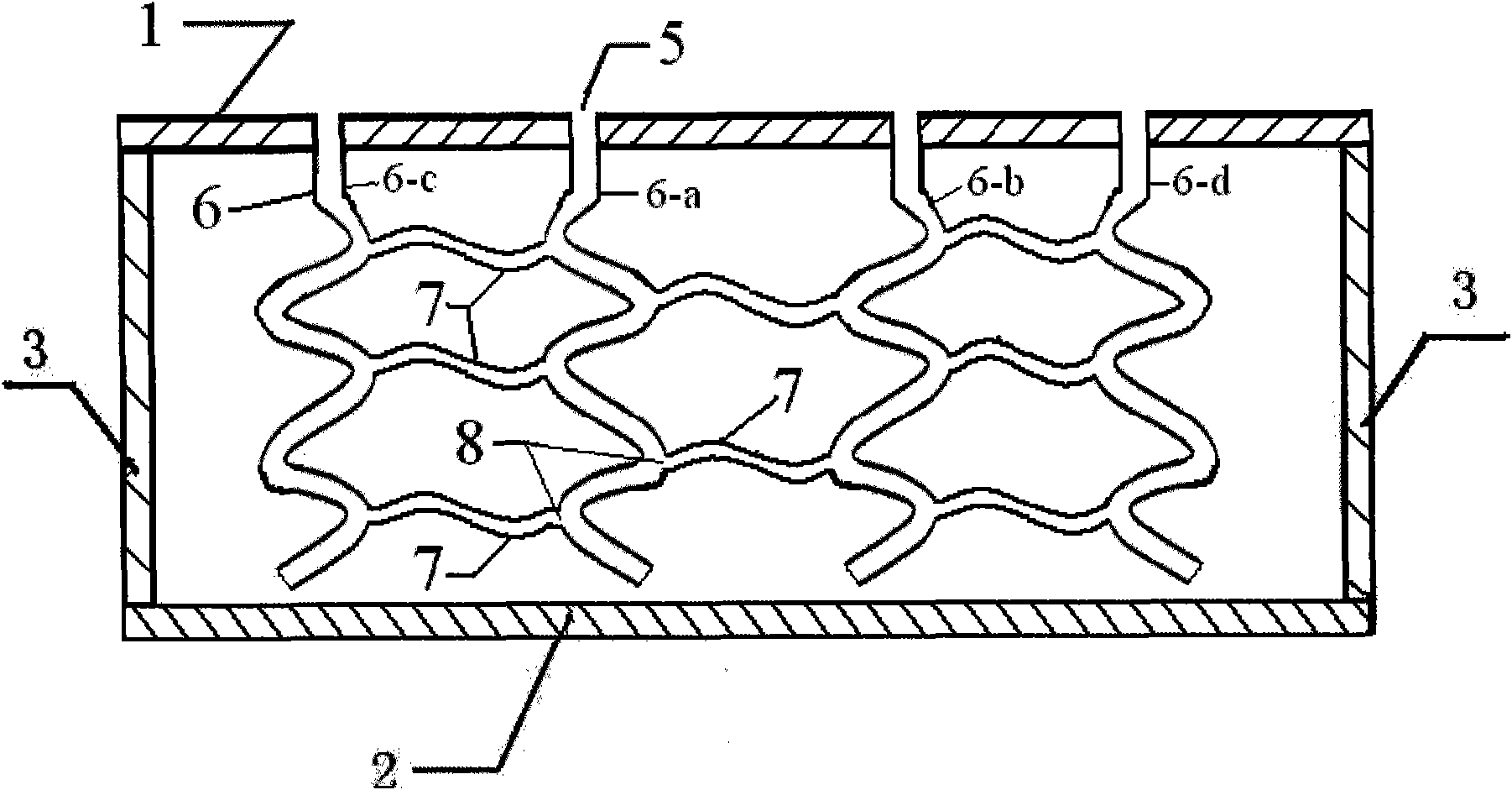

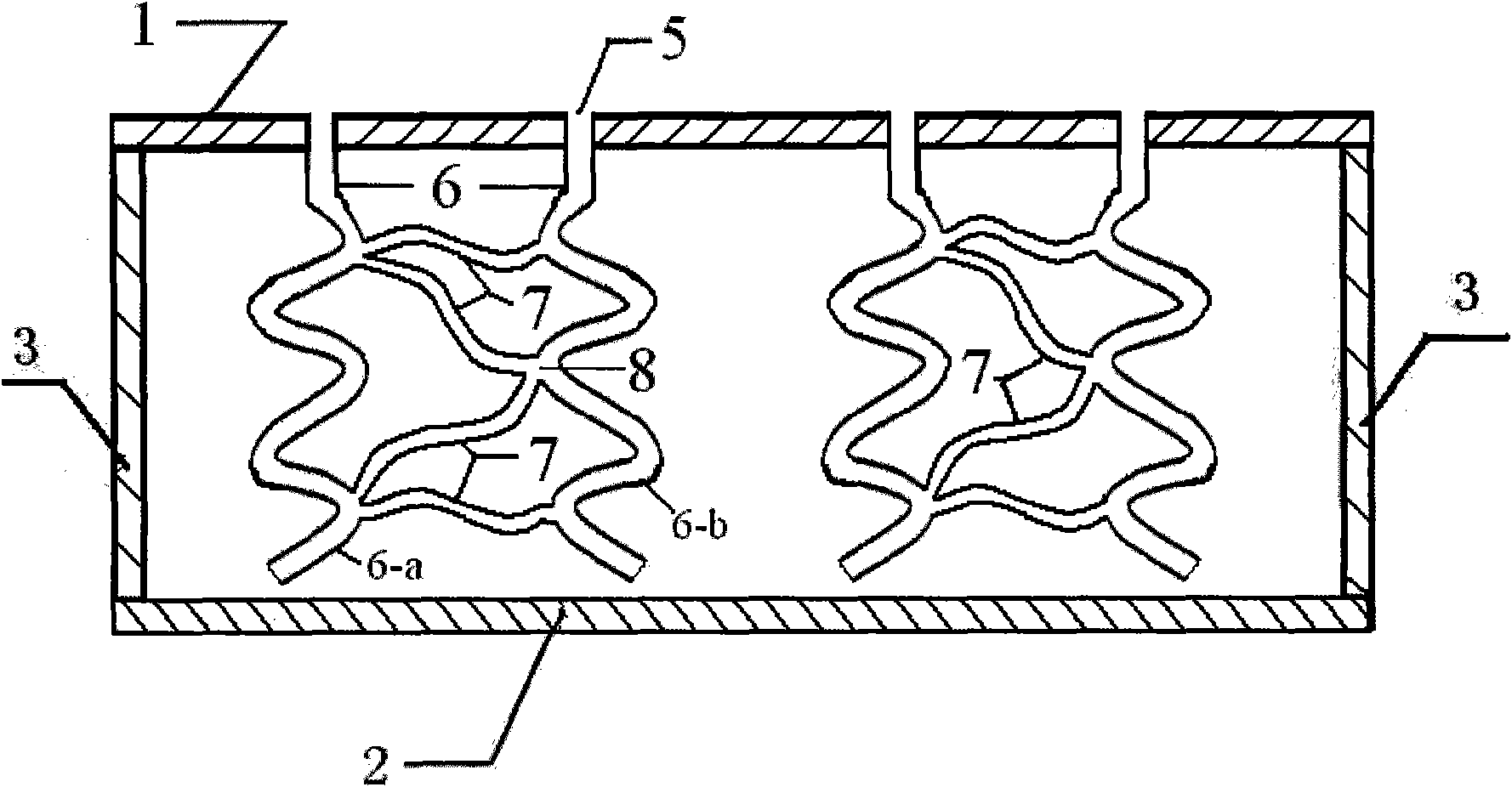

[0053] refer to figure 2 , In this embodiment, a sound absorbing device using coupling resonance between the lumen and coupling resonance between tube bundles is produced. The device is a closed cavity made of a perforated plate 1 made of stainless steel, a back plate 2 made of plexiglass and a side plate 3 made of plexiglass. The depth D of the closed cavity is 125 mm, and the perforated plate 1 is a side length of A 40 mm square stainless steel plate with a thickness of 0.8 mm. Holes 5 are provided on the perforated plate 1. The diameter of the holes 5 is 1.6 mm. The perforation rate of the holes 5 is 6.2%. The arrangement of the holes 5 on the perforated plate 1 is a regular square arrangement; 48 rubber-made main tube bundles 6 are installed on the holes 5 on the perforated plate 1 through the transition joint 4, and an open end of the main tube bundle 6 is connected with the perforated plate 1, and the number of the main tube bundles 6 is equal to the number of 5 holes. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com