A construction method of high-precision special-shaped thin-walled concrete cavity structure

A construction method and high-precision technology, applied in industrial buildings, building structures, formwork/formwork/work frames, etc., can solve problems such as the inability to meet construction accuracy, and achieve the coaxiality of the main shaft of the wind tunnel, easy operation, The effect of supporting the stability of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with example, accompanying drawing.

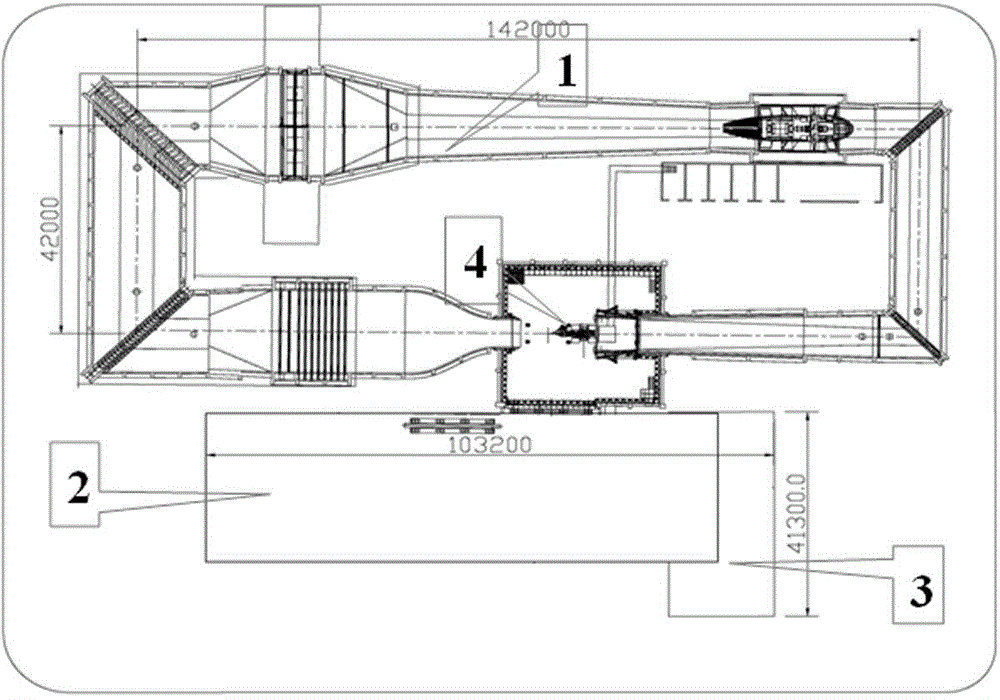

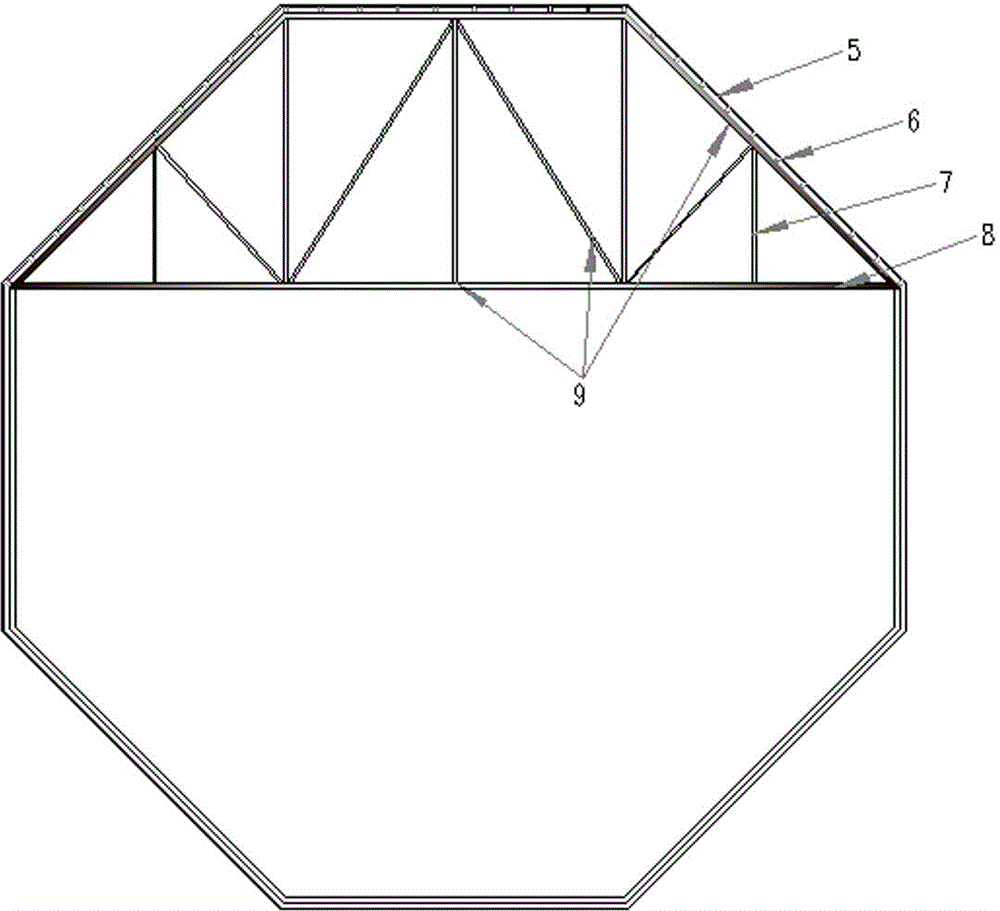

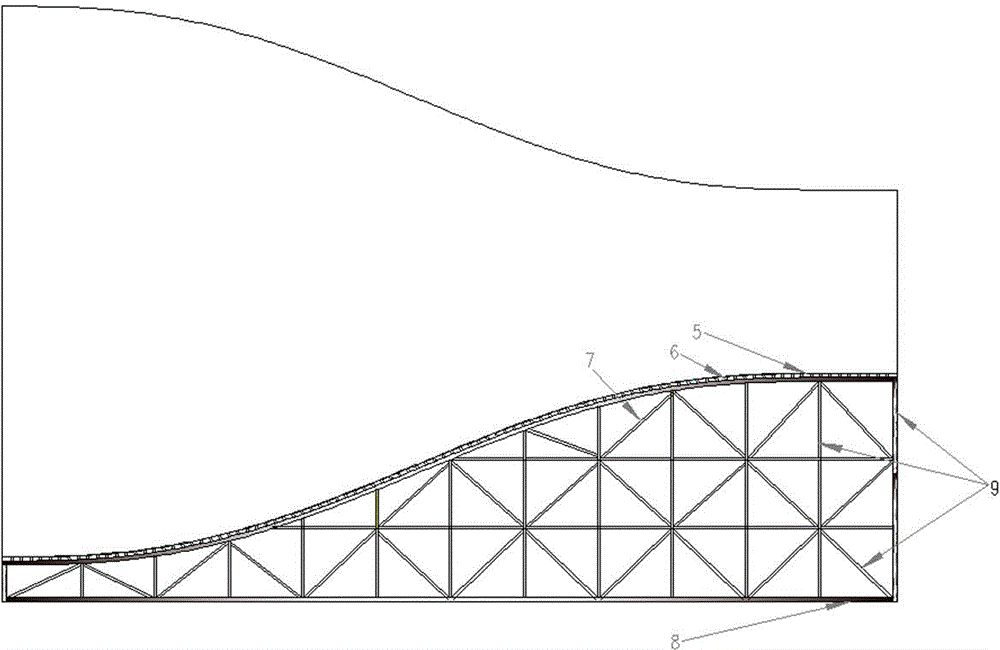

[0021] A continuous single-return wind tunnel is a high-precision ultra-large special-shaped thin-walled gradual cross-section concrete tunnel structure, the step difference of each section in the downstream direction is ≤2mm, the axis coaxiality is ≤φ4mm, and the axial coaxiality of individual sections is ≤φ4mm, and the precision requirements high. The specific construction process is as follows:

[0022] (1) Obtain 3D stereographic model and solid model:

[0023] According to the construction drawings, use the professional software SketchUp and Revit to establish the building information model, and obtain High-precision special-shaped thin-walled The continuity and precise spatial coordinates of the tunnel body, and the processed 1:100 special-shaped structure wind tunnel body 1 internal and external surface models can be intuitively expressed and effective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com