Multifunctional energy-saving buffer supercharger

A supercharger and multi-functional technology, which is applied in fluid pressure converters, safety devices, mining equipment, etc., can solve problems such as uneven water injection, power consumption, and equipment loss, and achieve good liquid injection effects, less equipment loss, and The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

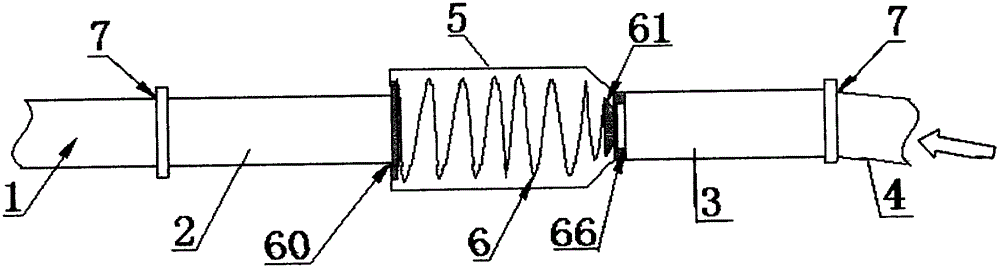

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

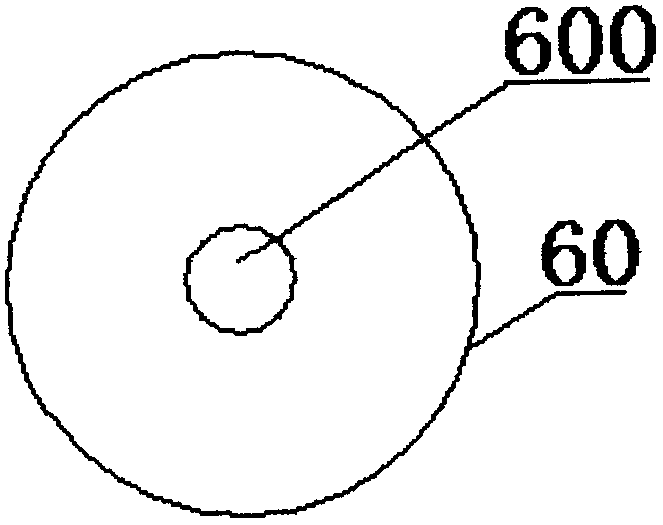

[0023] As shown in the figure, the multifunctional energy-saving buffer supercharger of the present invention includes a water injection pipe head 2 for connecting the water injection pipe 1 and a water supply pipe head 3 for connecting the high-pressure water supply pipe 4, and the water injection pipe head 2 and the water supply pipe head 3 Connect a section of tower-type variable-diameter pipe body 5 (sleeve) with a large front and a small rear. The variable-diameter pipe body 5 (sleeve) has a built-in tower-type booster spring 6 with a thick front and a thin back. The front-end assembly center of the booster spring 6 is Be shaped on the supercharging catch 60 of the diameter 2-3mm water hole 600, the valve plate 61 that the rear end of the supercharging spring 6 is equipped with the small diameter end (or sleeve pipe) of the reducing pipe body 5 or the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com