Heating device for pipeline

A heating device and pipeline technology, which is applied in the direction of pipeline heating/cooling, heating element shape, pipe/pipe joint/pipe fitting, etc., can solve the problems of affecting heating efficiency, heating device is not tightly bonded, etc., to increase heating efficiency, heating Visible, intensity-increasing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

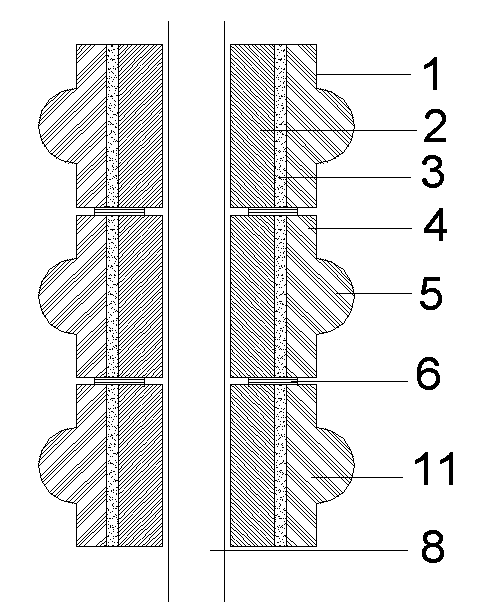

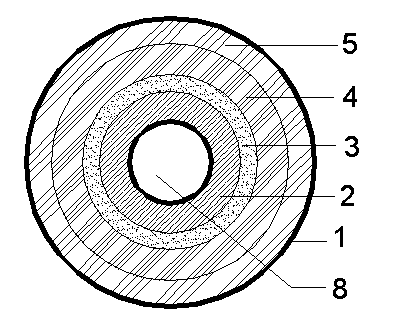

[0022] As shown in the figure, a heating device for pipelines includes a casing 1, in which a heating layer 2, an insulating layer 3 and a thermal insulation layer 4 are sequentially arranged, and the casing 1 is a split structure, consisting of two semicircular casings 11, connected into one body by fasteners, covering the outer wall of the pipe 8, wherein, the outer periphery of the semicircular shell 11 is provided with arc-shaped protrusions 5, and the two ends of the protrusions 5 are provided with hinges The connecting device 6 is connected by a hinge between the upper and lower semicircular shells 11;

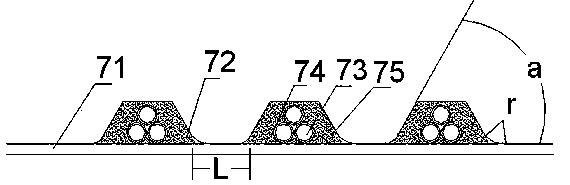

[0023] The heating layer 2 is formed by the cooperation of two electric heating belts 7, the electric heating belt 7 includes a housing 71, and the housing 71 is a belt-shaped structure, wherein the housing 71 is a A plurality of protrusions 72 are provided on the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com