A program-controlled constant current source degaussing device and degaussing method

A program-controlled constant current source and degaussing device technology, applied in the erasing method, recording/reproducing/deleting method, etc., can solve the problems of long charging time, capacitor damage, unstable charging current, etc., to shorten the charging time, The effect of prolonging life and improving degaussing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

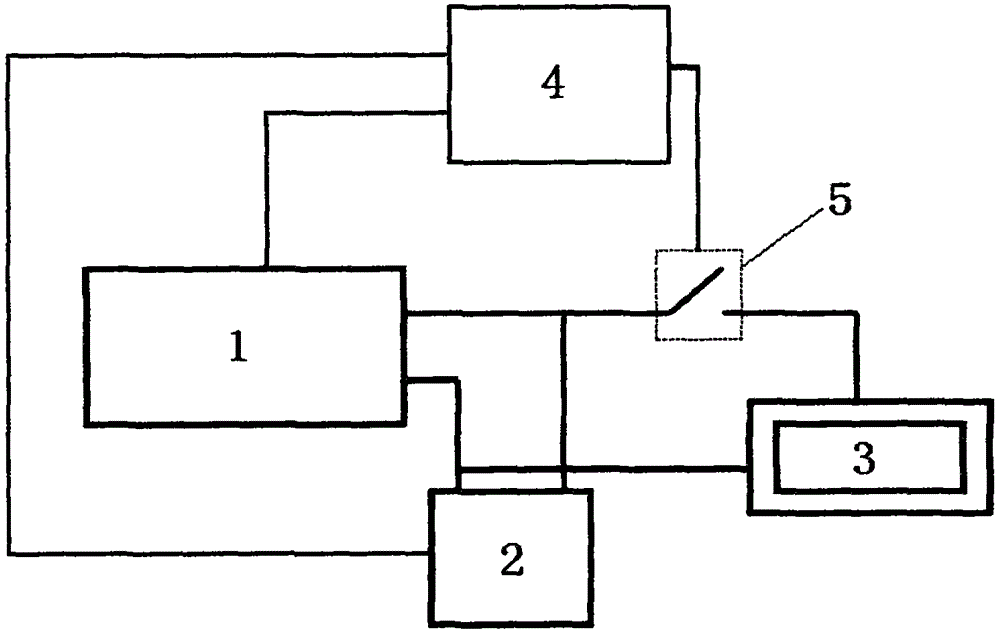

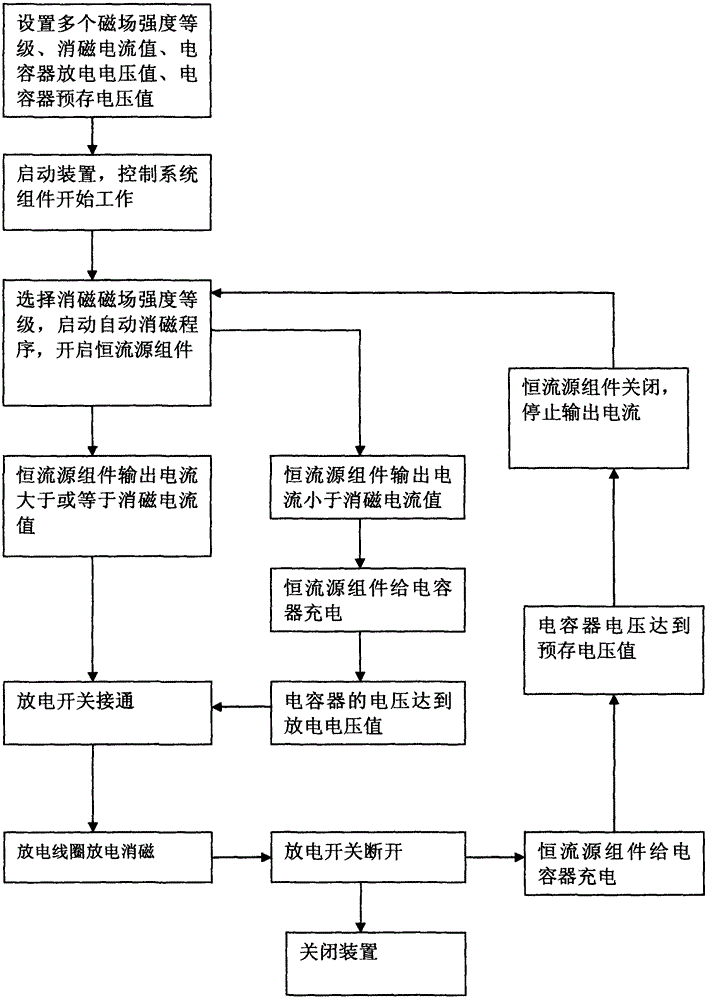

[0024] figure 1 , figure 2 It is a preferred embodiment of the program-controlled constant current source degaussing device, figure 1 The program-controlled constant current source degaussing device comprises a constant current source assembly 1, a capacitor 2, a discharge coil 3, a discharge switch 5 and a control system assembly 4; In parallel with the capacitor 2, the control system component 4 is connected with the constant current source component 1, the discharge switch 5 and the capacitor 2, and monitors and controls them; the constant current source component 1 can convert the external power supply into a constant current output.

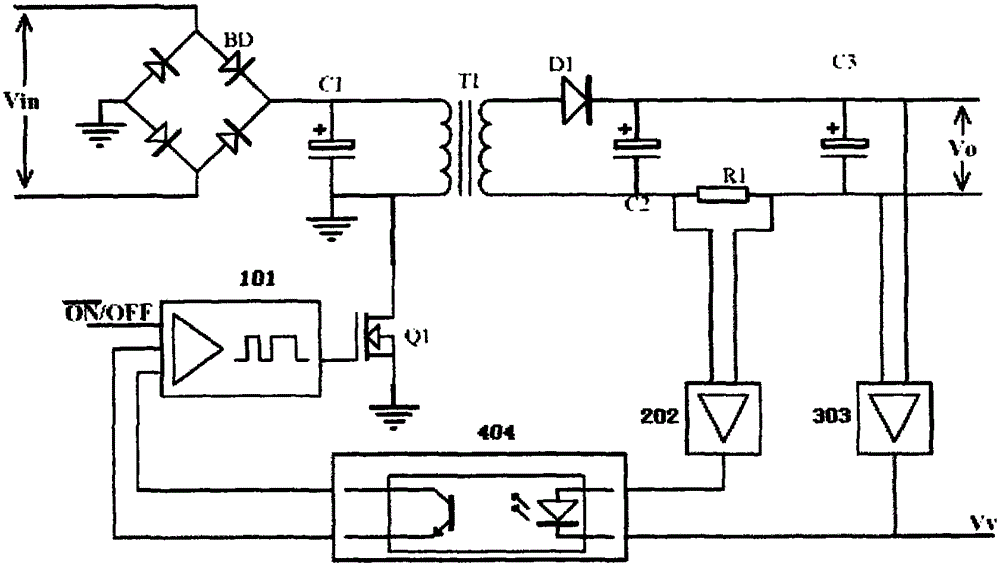

[0025] figure 2 It is a circuit diagram of a constant current source assembly, the DC output terminal Vo of the constant current source assembly 1 is used to connect with the capacitor 2 and the discharge coil 3; the constant current source assembly 1 has a voltage sampling signal output terminal Vv connected to the control system assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com