Equipment abrasion state wireless monitoring device based on internet of things

A technology of wireless monitoring device and wear state, which is applied in the direction of mining equipment, mining equipment, signal transmission system, etc., can solve the problem of not being able to real-time, reduce the safety factor of traction wheel mining special equipment, and the wear state of traction wheel rope groove cannot be automatically Early warning and other issues to achieve the effect of improving the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

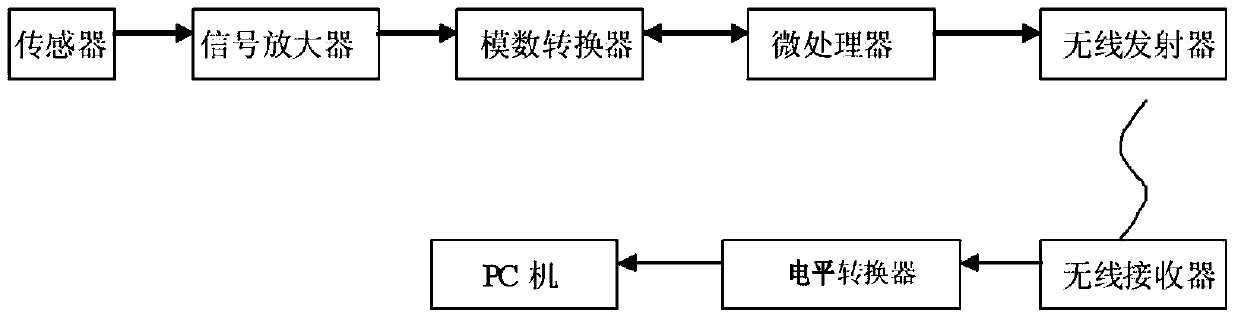

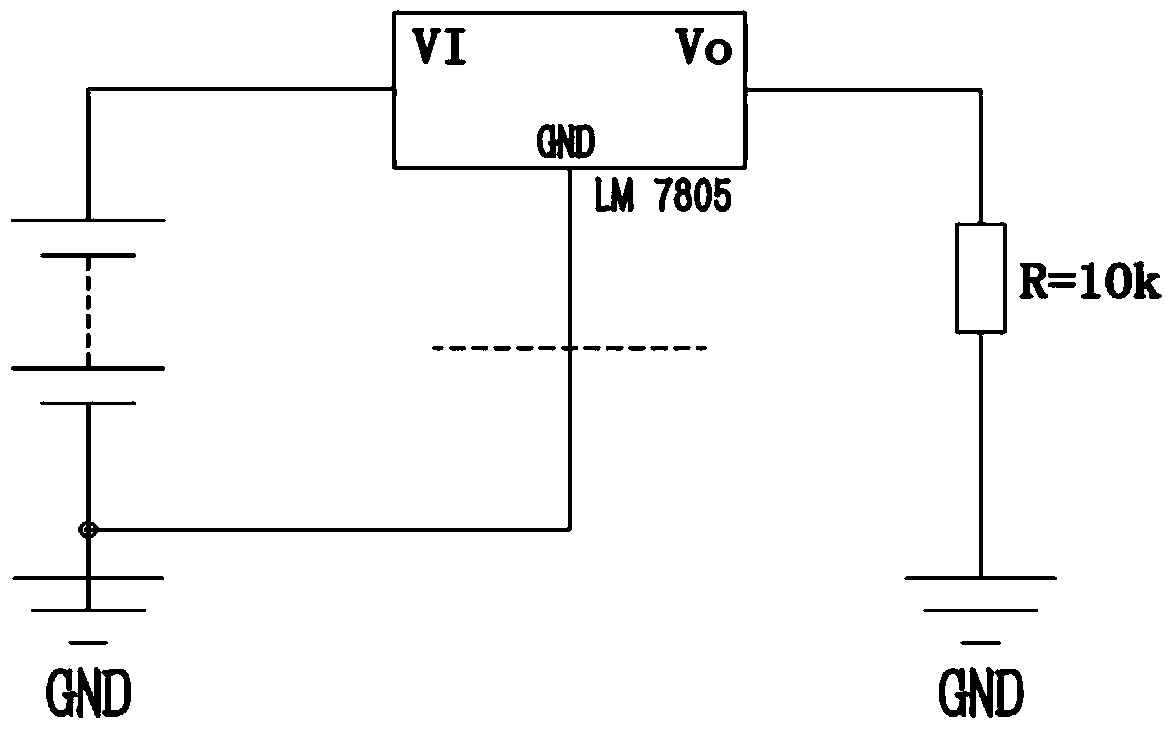

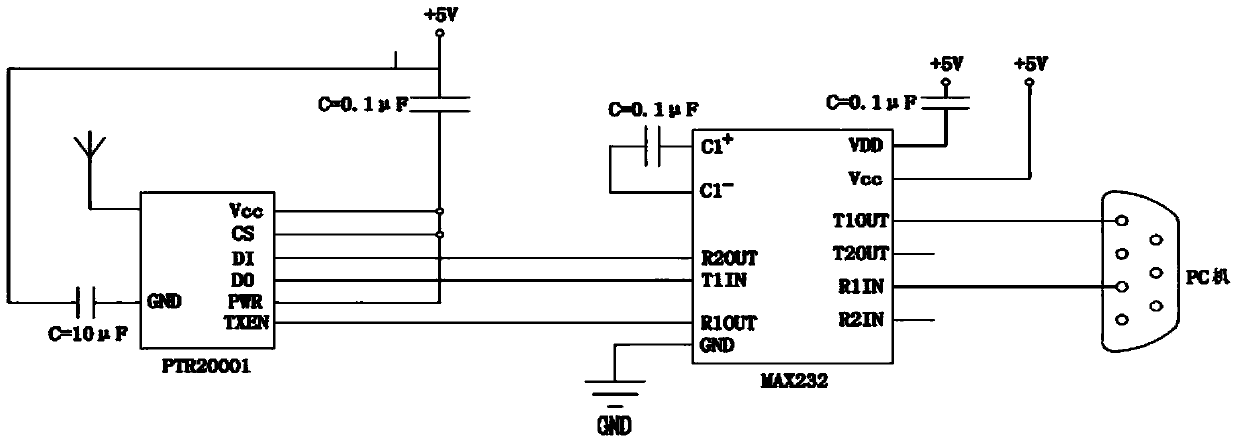

[0016] like Figure 1 to Figure 4 As shown, the present invention includes a power supply module, a wireless monitoring transmission module and a wireless monitoring system module, such as figure 1 As shown, the wireless monitoring transmission module includes a sensor, a signal amplifier, an analog-to-digital converter, a microprocessor, and a wireless transmitter connected in sequence. The sensor sends the collected signal to the signal amplifier for amplification, and the amplified signal is generated by the analog The digital converter is converted into a digital signal and sent to the microprocessor, and the wireless transmitter is controlled by the microprocessor to send. The wireless monitoring system module includes a wireless receiver, a level converter and a PC connected in sequence. The wireless receiver receives signals from The signal sent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com