Device and method for compression-consolidation of parts made of composite materials having a thermoplastic matrix reinforced with continuous fibers, especially of natural origin

A technology of continuous fibers, thermoplastic polymers, applied in the field of devices and methods for compression-consolidation of parts made of composite materials having a thermoplastic matrix reinforced with continuous fibers of particular origin, capable of solving the problem of wrinkling , wrinkling, production rate is not allowed and other problems, to achieve the effect of improving the heat dissipation coefficient and enhancing the enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

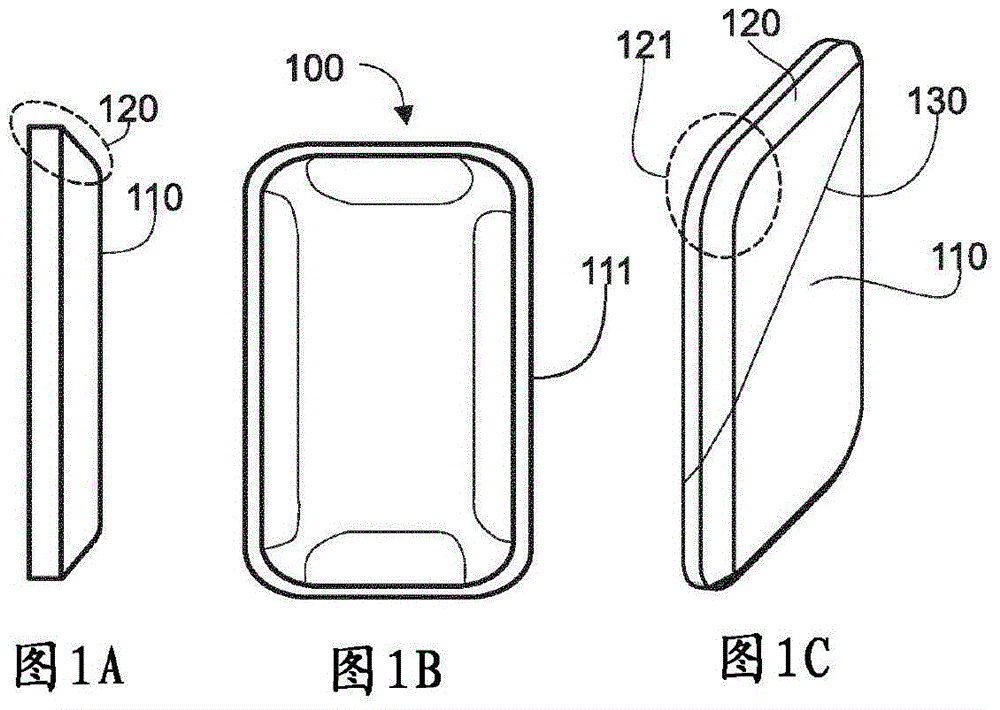

[0045] exist figure 1 Among them, according to an example of implementation, the part 100 that is the object of the invention has the shape of a half-shell comprising a bottom 110 and a flanged edge 120 . The profile 111 of the part 100 is continuous so that the part includes a non-developable area 121 with a triangular connection between the flanged edge 120 and the bottom 110, which is called a "corner fitting". The bottom is shown here as a plane. According to a better embodiment (not shown), the bottom can be formed according to a curved surface in the form of a double arc. Said part 100 consists of a laminated composite material comprising a plurality of plies comprising so-called continuous fibers 130 . So-called continuous fibers extend from one side of the part 100 to the other in a continuous fashion. According to a better embodiment, said fibers consist of reconstituted continuous fibers or monomeric continuous fibers formed of a group of fiber filaments, for exa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com