Method and machine set for cleaning gravel ballast from sieve tracks

A mechanical group and stone crushing technology, applied in the field of mechanical group, can solve problems such as inability to match crushed stones and ballast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

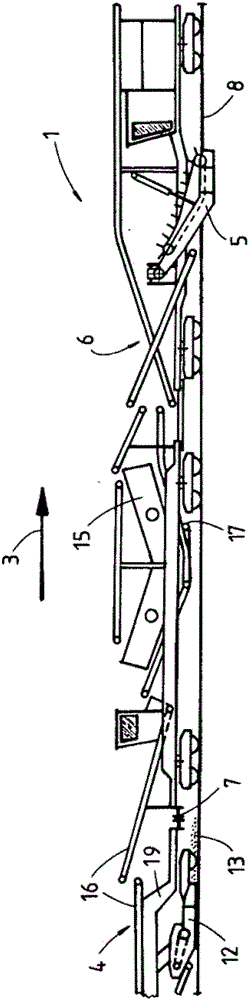

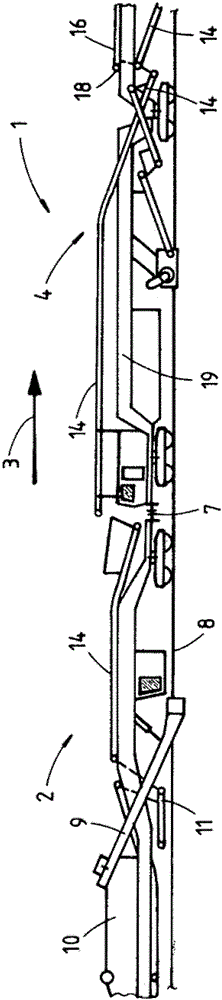

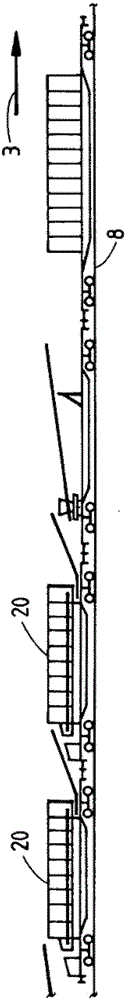

[0015] figure 1 with 2 The machine group 1 shown is composed of a first machine 2 designed as a screen cleaning machine, a second machine 4 arranged in front of the working direction 3 and a ballast excavation machine arranged in front of the second machine 4 and equipped with a ballast bed slope. The third mechanism 6 of the device (Flankenaushubvorrichtung) 5 consists. The machines 2 , 4 , 6 are connected to each other via coupling means 7 and can run on rails 8 .

[0016] The first machine 2 has a sweeping chain 9 which runs endlessly around the track 8 and a first screening device 10 which can be fed by the sweeping chain 9 . Next to the cleaning chain 9 back is the unloading position 11, which is used to unload the cleaned crushed stone ballast on the track 8.

[0017] The second machine 4 has a machine frame 19 consisting of two parts, and the second machine 4 is equipped with a receiving device 12 for collecting the cleaned crushed stone ballast 13 stored on the trac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com