Improved type synchronous mechanism and hybrid power transmission thereof

A synchronous mechanism and hybrid technology, applied in the direction of mechanical drive clutches, clutches, power units, etc., can solve the problems of long synchronization time, difficulty in shifting, and the overall efficiency of the transmission is reduced, and achieves the effect of low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

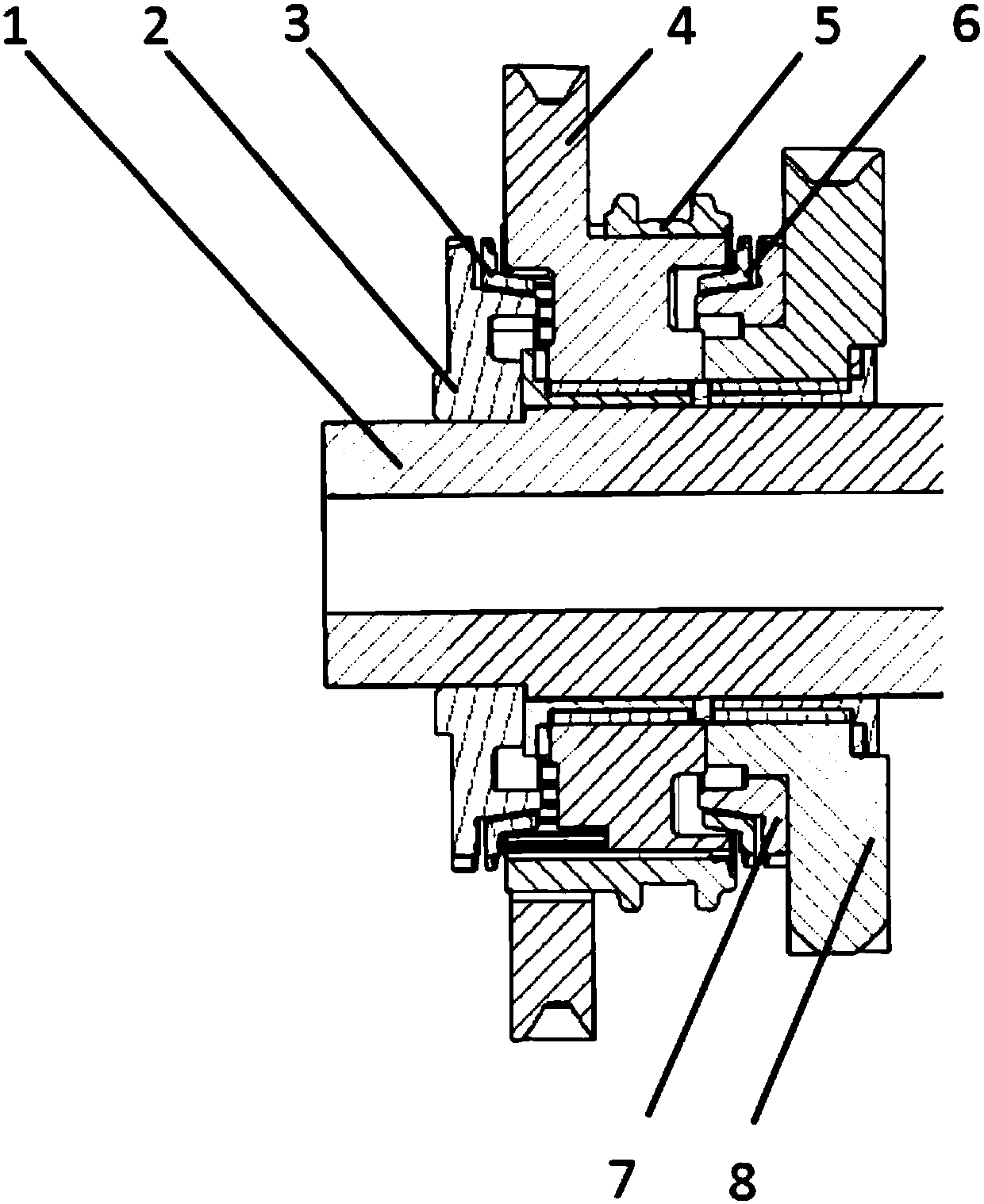

[0022] like figure 1 As shown, the improved synchronizing mechanism of this embodiment includes: the charging gear coupling tooth 2 and the EV gear driving gear 8 arranged oppositely, and the charging block synchronizing ring 3 and the motor transmission gear sleeved on the charging gear coupling tooth 2 in sequence. 4 and the synchronous gear sleeve 5 and the EV gear joint tooth 7 and EV gear synchronizing ring 6 which are sequentially sleeved on the EV gear driving gear 8, when the synchronizing gear sleeve 5 is turned to the left, it passes through the charging gear synchronizing ring 3 and is connected with the charging gear. When the gear tooth 2 is combined, the torque can be transmitted between the motor transmission gear 4 and the shaft 1; the synchronous gear sleeve 5 is dialed to the right, and after passing through the EV gear synchronizing ring 6, it is combined with the EV gear combining tooth 7, and the torque can be transmitted in the motor. The transmission bet...

Embodiment 2

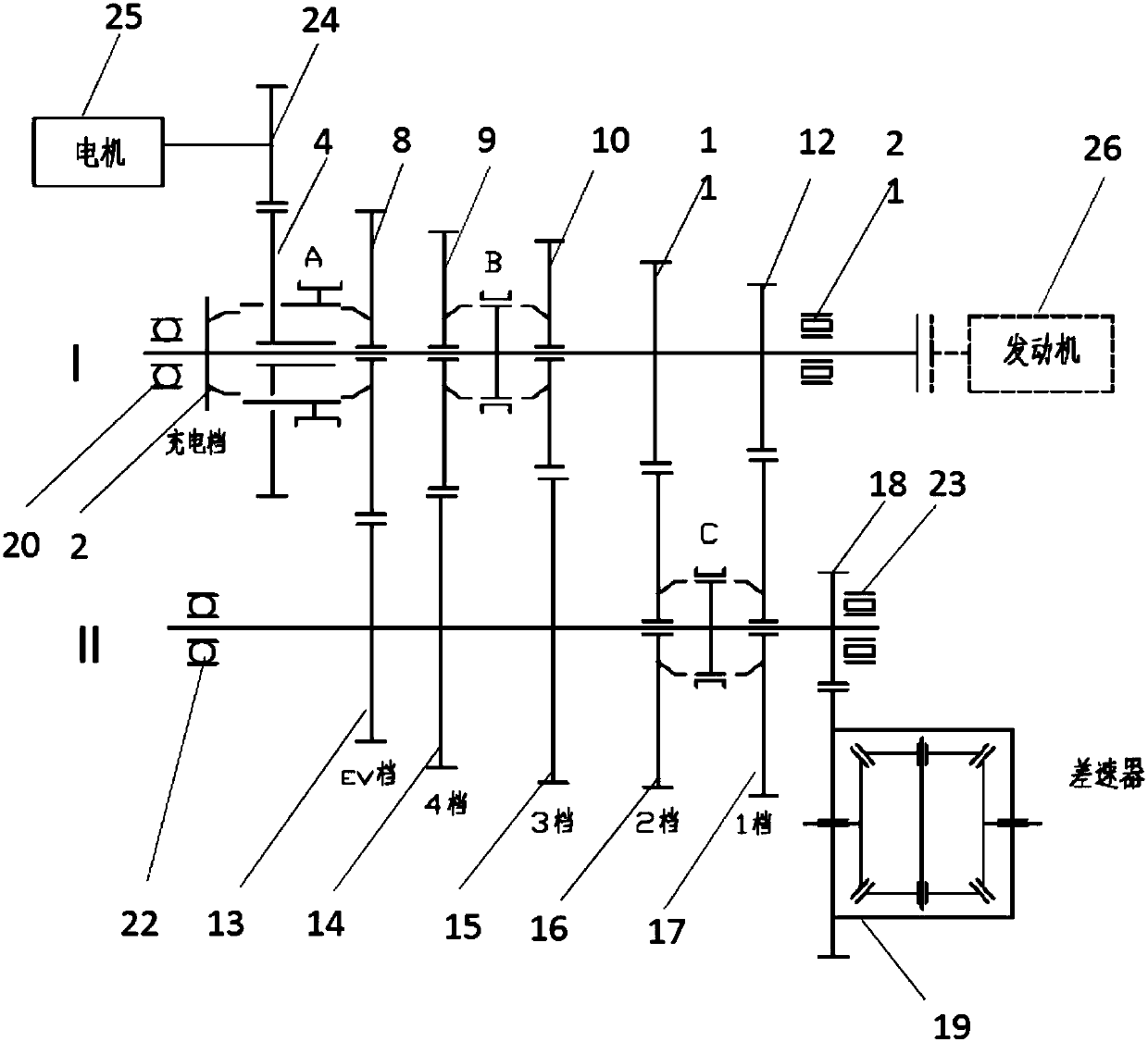

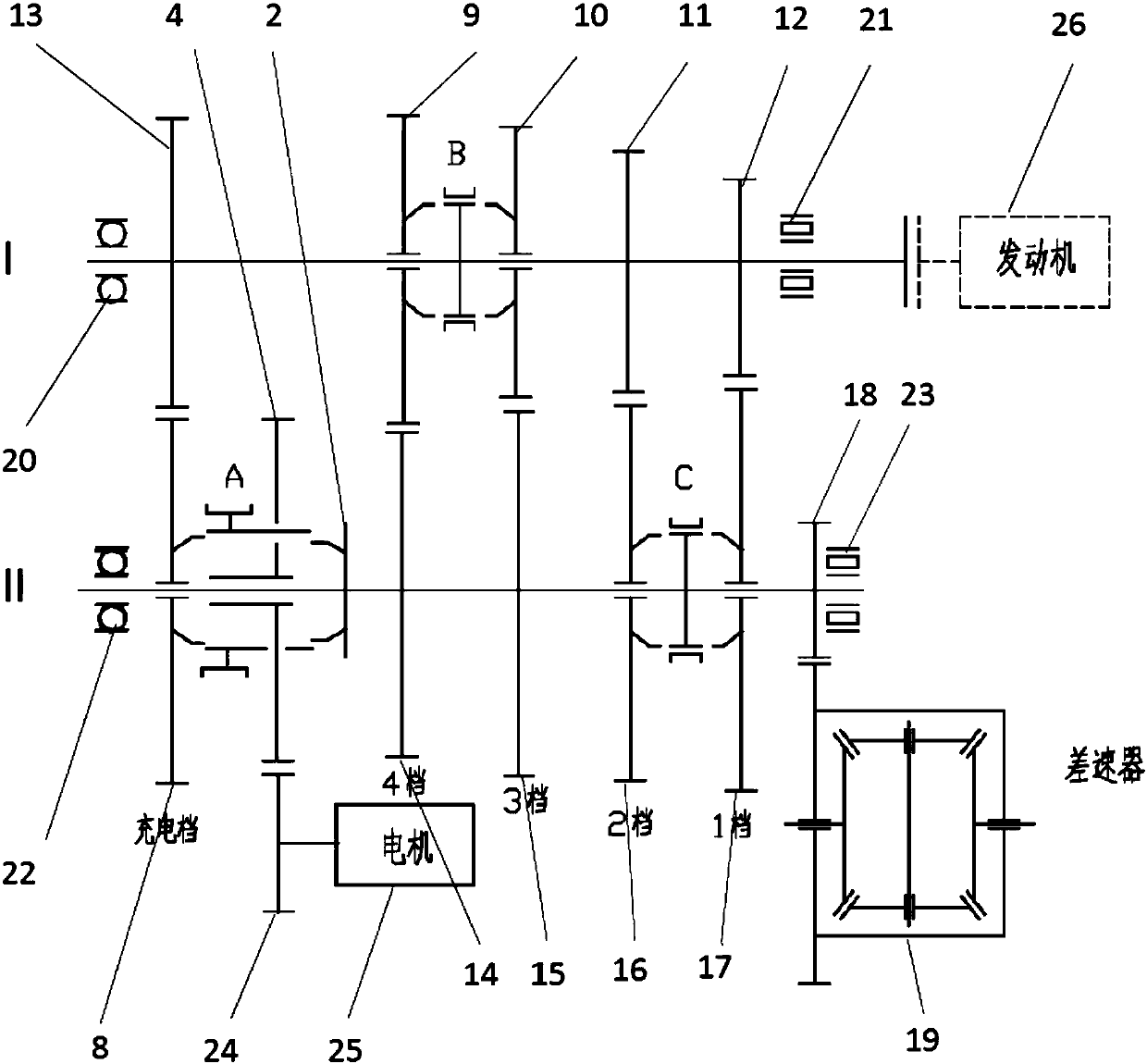

[0042] like image 3 As shown, this embodiment relates to a transmission for hybrid power based on the above-mentioned improved synchronous mechanism, including: a second synchronous mechanism B arranged on the input shaft I, connected with the motor transmission gear 4 and sleeved on the output shaft II The improved synchronous mechanism A and the third synchronous mechanism C, the input shaft is successively provided with an EV gear driven gear 13, a fourth gear driving gear 9, a third gear driving gear 10, a second gear driving gear 11 and a first gear driving gear 12, The output shaft is successively provided with a fourth gear driven gear 14, a third gear driven gear 15, a second gear driven gear 16, a first gear driven gear 17 and a main reduction driving gear 18, wherein: the EV gear driven gear 13 and the improved The driving gears of the EV gear of the type synchronous mechanism are meshed, the driving gears from the fourth gear to the first gear are meshed with the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com