Method of controlling pitch systems of a wind turbine

A technology for wind turbines and controllers, applied in the directions of wind turbines, engine control, wind turbine control, etc., can solve problems such as power output reduction, and achieve the effect of reducing maintenance work and minimizing tower oscillation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

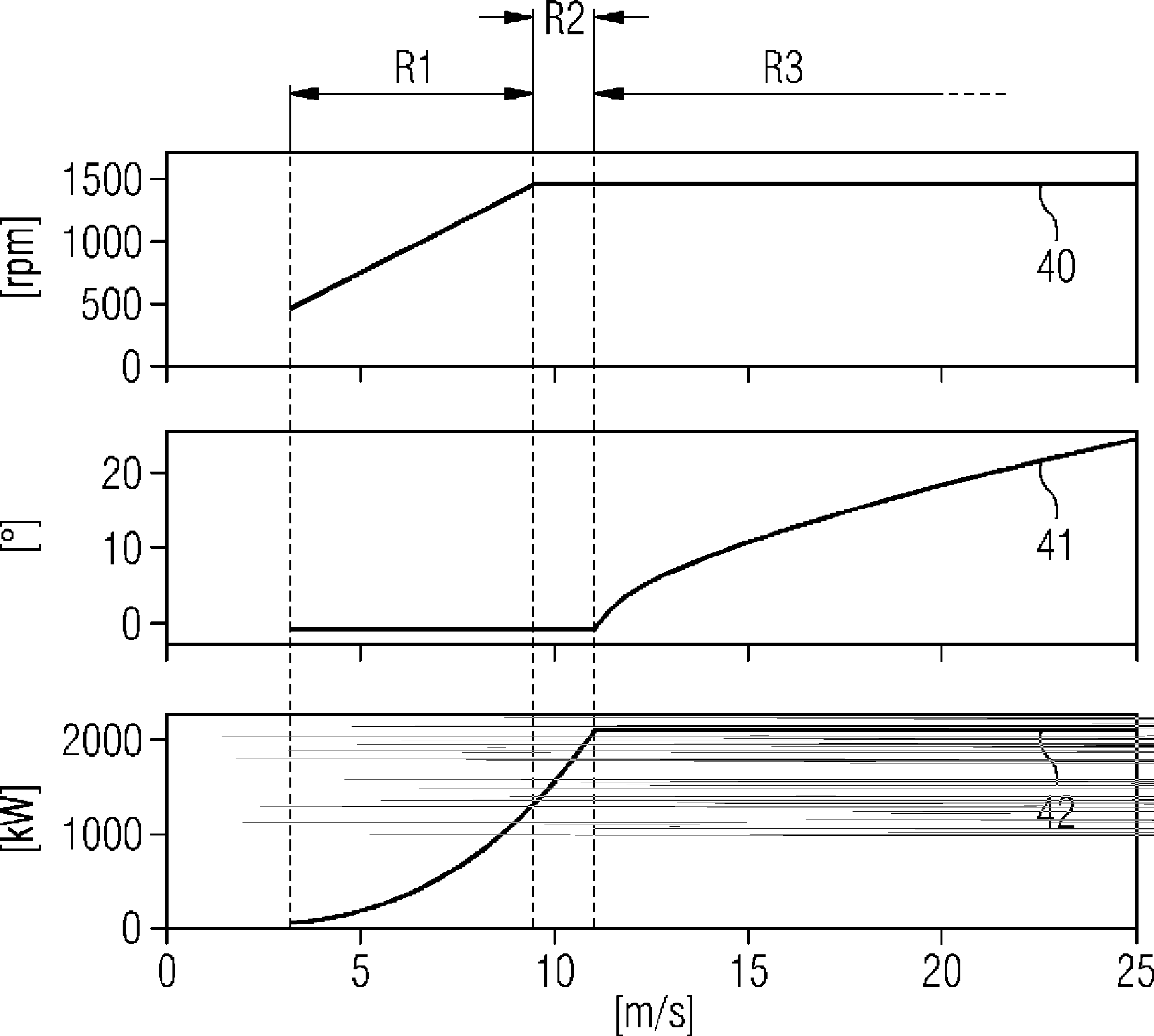

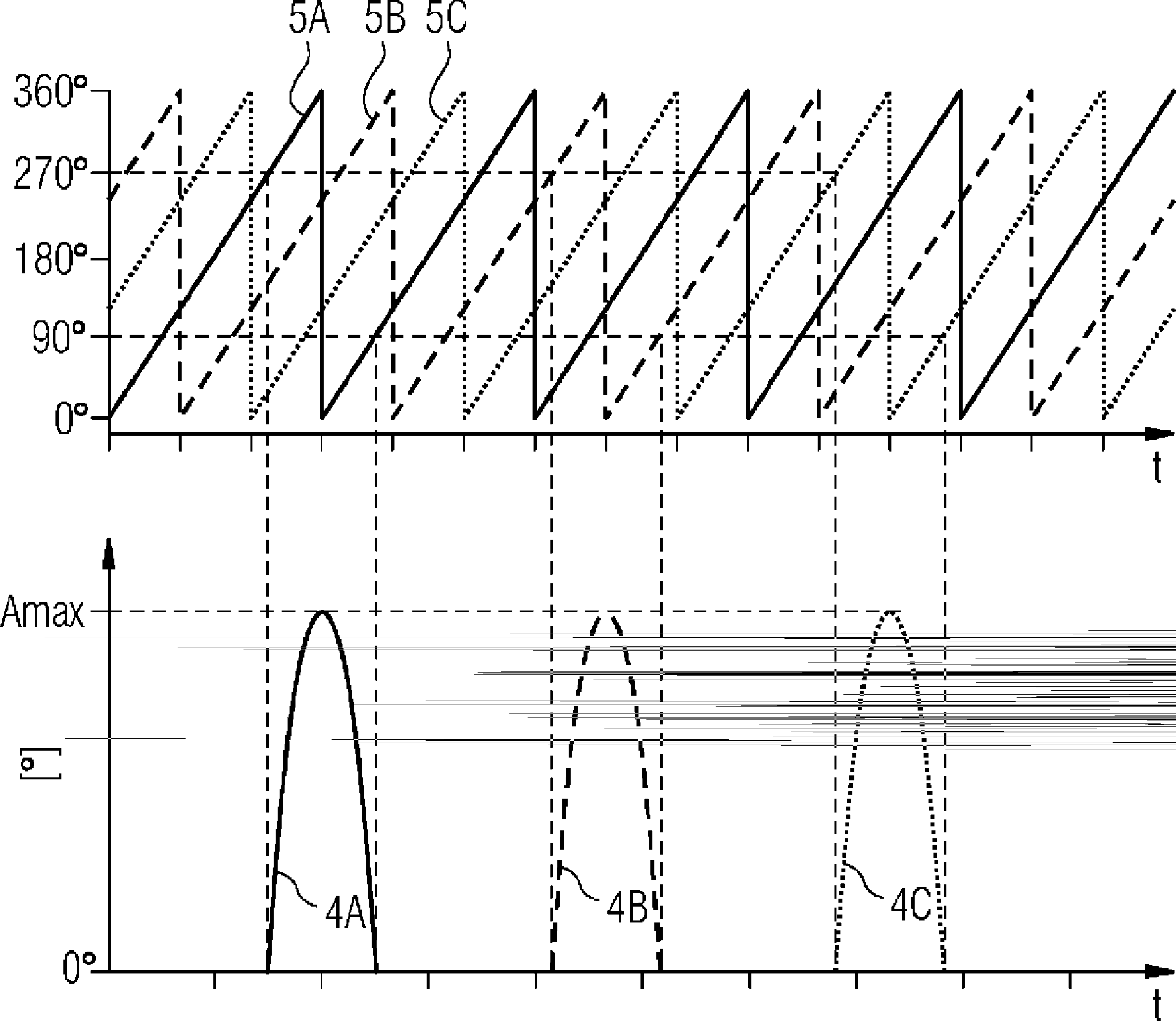

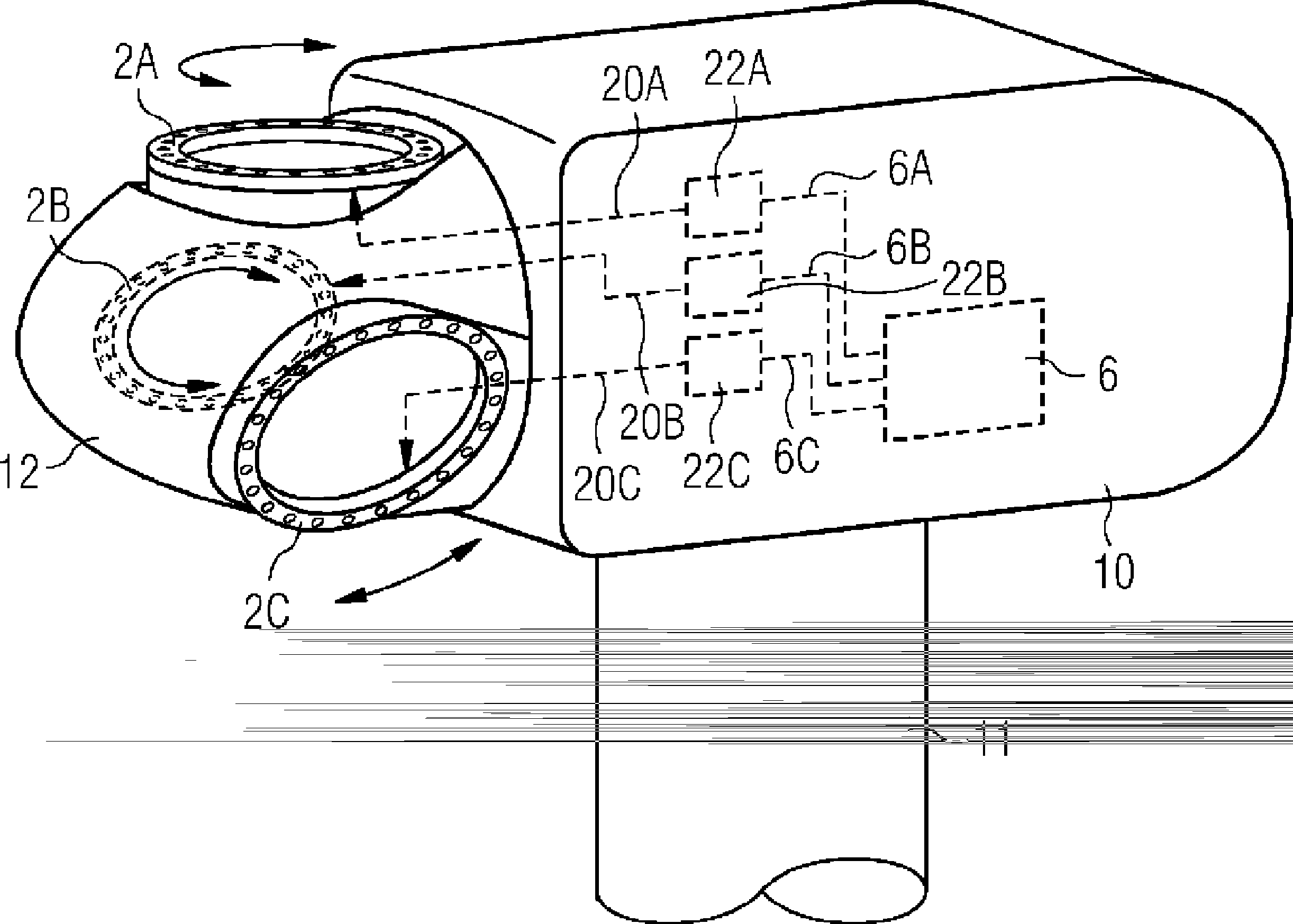

[0038] figure 1 An exemplary wind turbine 1 is shown with a nacelle 10 mounted on a tower 11 and a number of blades 3A, 3B, 3C connected to a hub 12 . When the wind W exerts a force on the blades 3A, 3B, 3C, they are caused to rotate (in this example, the blades 3A, 3B, 3C rotate clockwise when viewed from the front, as indicated by the arrow R). The wind turbine controller can drive the yaw ring to rotate the nacelle 10 in direction Y such that the hub 12 is substantially always facing the wind. The wind turbine controller is also able to control the pitch position of each rotor blade 3A, 3B, 3C such that the blades 3A, 3B, 3C are oriented at an optimal pitch angle. This allows the best possible conversion of wind energy into the rotational motion of the hub and rotor. The rotor blades 3A, 3B, 3C define a vertical plane P of rotation. The vertically arranged blade 3A in this figure is shown in a reference position at 0° in this plane P. As shown in FIG. When this blade 3A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com