Complex molding comb tooth cutter

A technology of comb teeth and cutting tools, which is applied in the field of the edge strengthening belt structure of complex forming comb teeth cutting tools, can solve the research on edge strengthening of cutting edge tools without complex cutting edge, the high probability of edge breakage of rough cutting teeth, and the poor surface finish of processed workpieces, etc. To improve the surface finish, reduce the probability of edge chipping, and improve the overall performance of the tool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

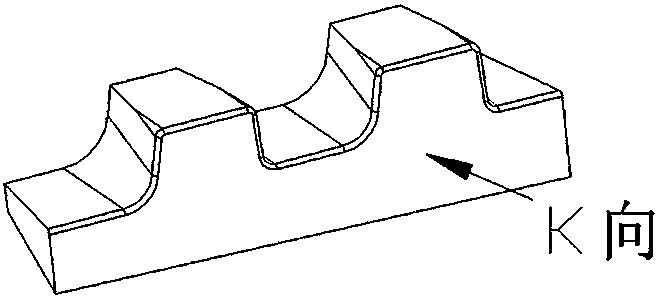

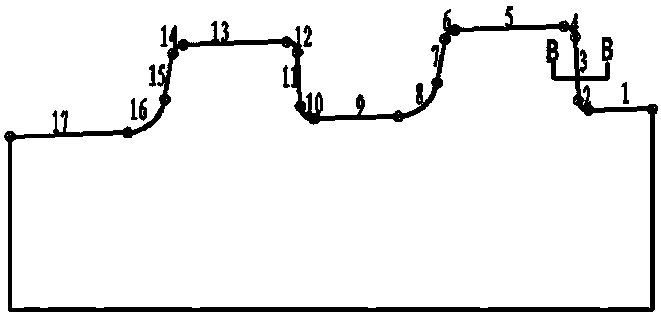

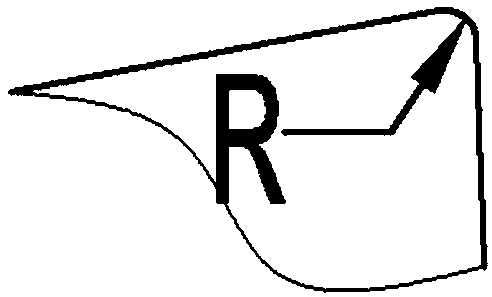

[0020] The complex forming comb cutter is divided into fine cutting teeth and rough cutting teeth. The number of teeth is 2, and there is one fine cutting tooth and one rough cutting tooth. figure 1 , figure 2 For the comb cutter in the middle, the teeth on the right are fine cutting teeth, and the teeth on the left are rough cutting teeth. figure 1 , 2 The shown complex shaped comb cutter consists of straight blade 1, straight blade 3, straight blade 5, straight blade 7, straight blade 9, straight blade 11, straight blade 13, straight blade 15, straight blade 17, arc blade 2, Arc edge 4, arc edge 6, arc edge 8, arc edge 10, arc edge 12, arc edge 14, arc edge 16 form. Among them, the cutting edges 1-9 are fine cutting teeth, and the cutting edges 10-17 are rough cutting teeth. The dimensions of the edge strengthening band described below are defined as the fillet radius of the cutting edge.

[0021] Dimension R of the edge strengthening band in the rough cutting tooth are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com