Pneumatic hydraulic jack

A pneumatic hydraulic jack technology, applied in the field of hydraulic jacks, can solve the problems of increased cost, increased turbulent flow, complex processing and manufacturing, etc., to achieve the effects of reducing temperature rise and pressure loss, prolonging service life, and increasing applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

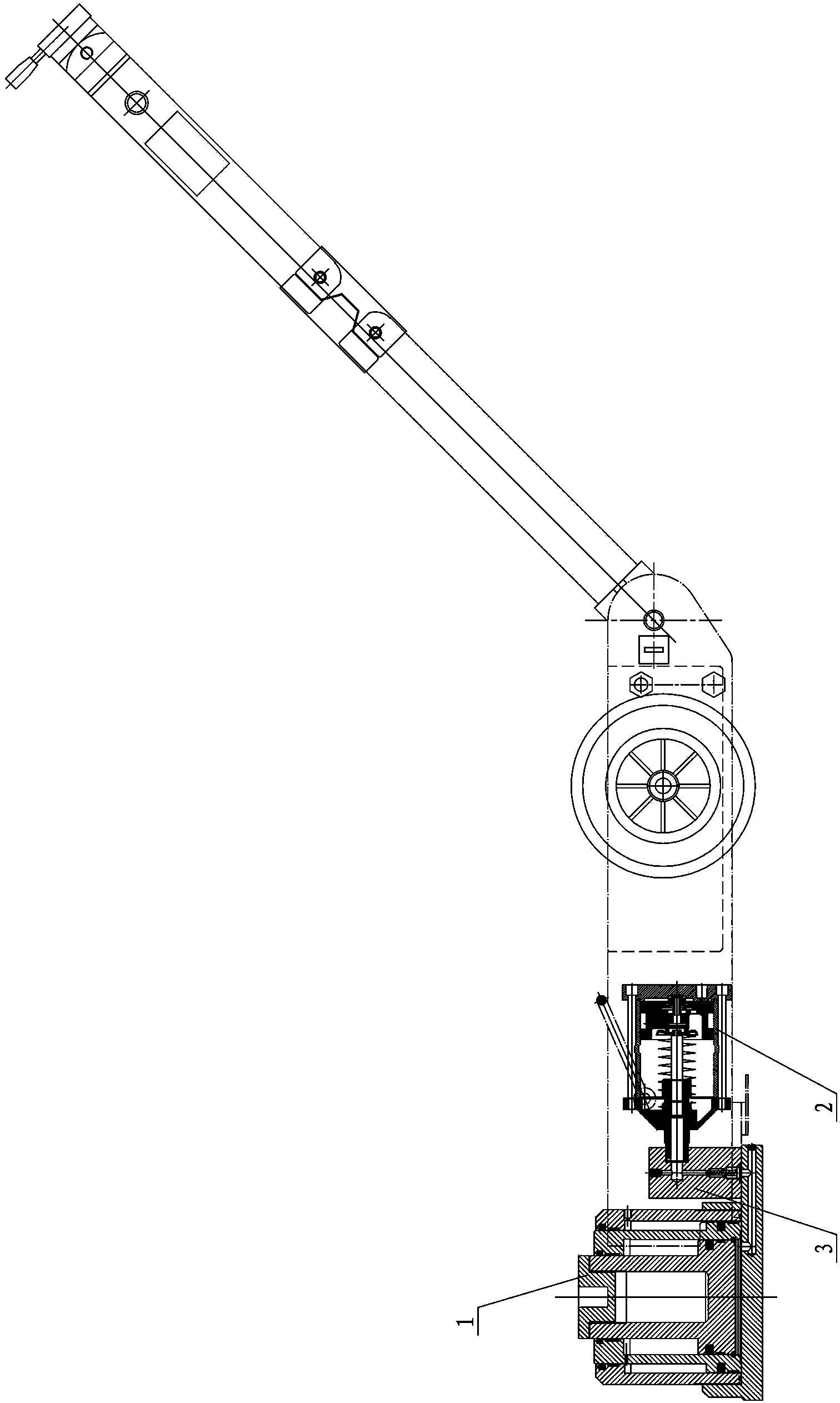

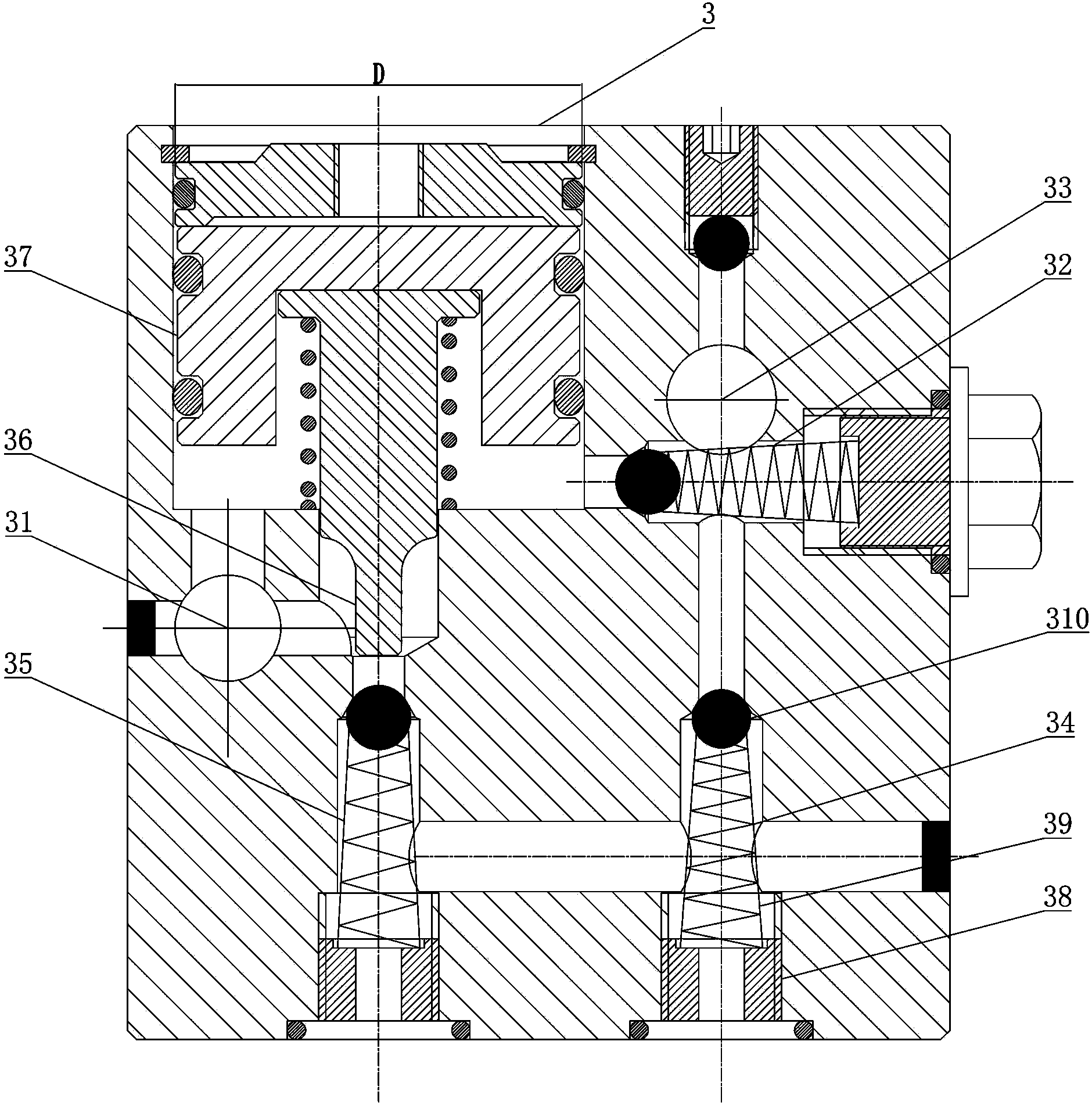

[0014] figure 1 A specific embodiment of the pneumatic hydraulic jack of the present invention is shown, and the pneumatic hydraulic jack includes a jacking cylinder 1 , an oil tank, a transition plate 3 and a pneumatic booster 2 . Such as figure 2 As shown, the transition plate 3 is provided with an oil supply passage and an oil return passage. The oil tank is connected to the jacking cylinder 1 through the oil supply passage on the transition plate 3, and the hydraulic oil pump is driven by the pneumatic booster 2 connected to the oil supply passage. Into the jacking cylinder 1, the oil supply channel of the transition plate 3 is provided with an oil inlet and outlet interface 31, a first check valve 32, a plunger pump interface 33 and a second check valve connected with the jacking cylinder 1 in sequence. 34, the second one-way valve 34 is arranged vertically and on the same axis as the plunger pump interface 33, and the first one-way valve 32 is horizontally arranged in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com