Ladder tower flocculation reaction device

A reaction device and flocculation technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of complex structure of the tank body, uneven mixing reaction, easy mud accumulation at the end, etc., achieve short flocculation time, improve effective collision rate, The effect of small head loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

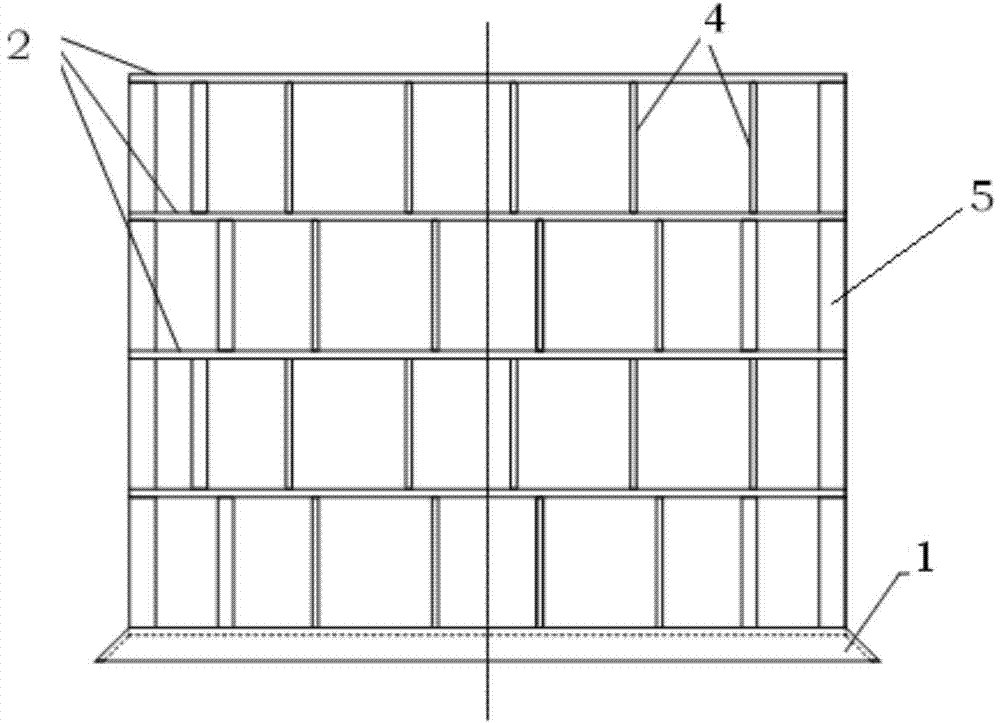

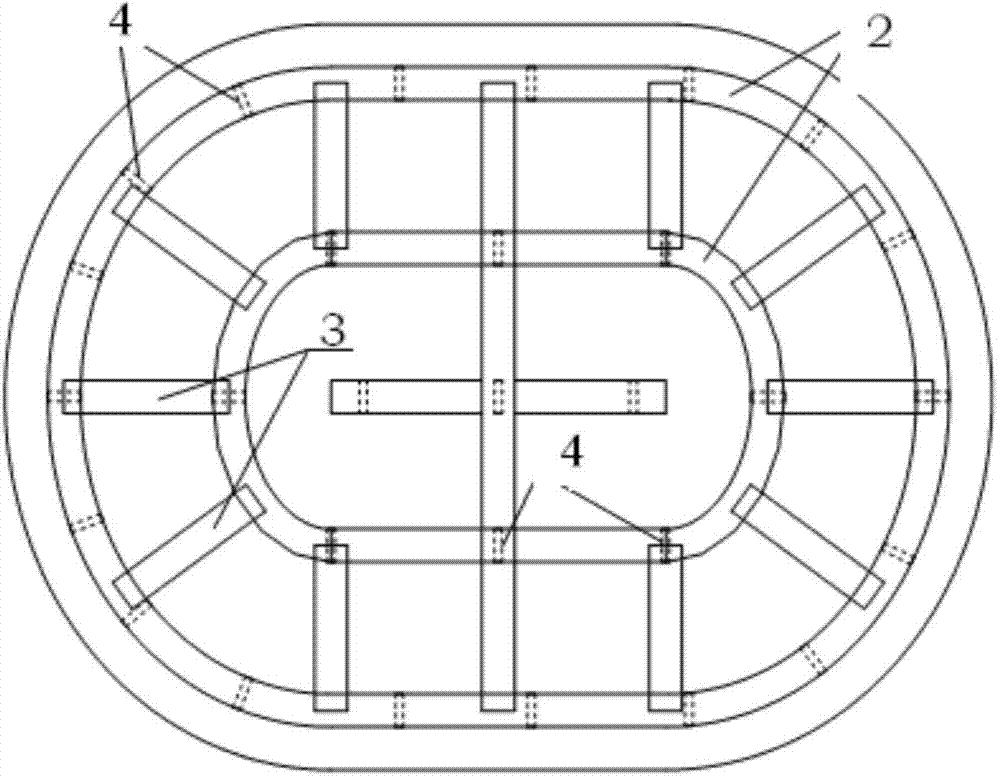

[0019] The basic structure of the ladder column flocculation reaction device is as follows: figure 1 , 2 As shown, the lower end of the tower 5 is provided with a trumpet-shaped flare 1, two circles of elliptical stepped platforms 2 and (m-shaped) tie bars 3 are provided in the horizontal direction, and a supporting partition 4 is provided in the vertical direction. There is a cross-shaped baffle in the middle, and the step plate and tie bars, including the supporting partition and the step plate, are connected by welding or bolts. The reaction device can be made of polypropylene or stainless steel.

[0020] The ladder tower flocculation reaction device, as an important flocculation component in the coagulation and sedimentation process section of water supply and wastewater treatment, can be designed in a modular manner and installed in an integrated flocculation sedimentation tank. The equipment itself has no mechanical rotating parts, no energy consumption, and the overall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com