Composite filter core of water purifier

A compound, pure water machine technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve high production costs and after-sales maintenance costs, and high water leakage risk coefficient , the large internal space of the machine, etc., to achieve the effect of easy maintenance and replacement, reduced material costs and labor costs, and less space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

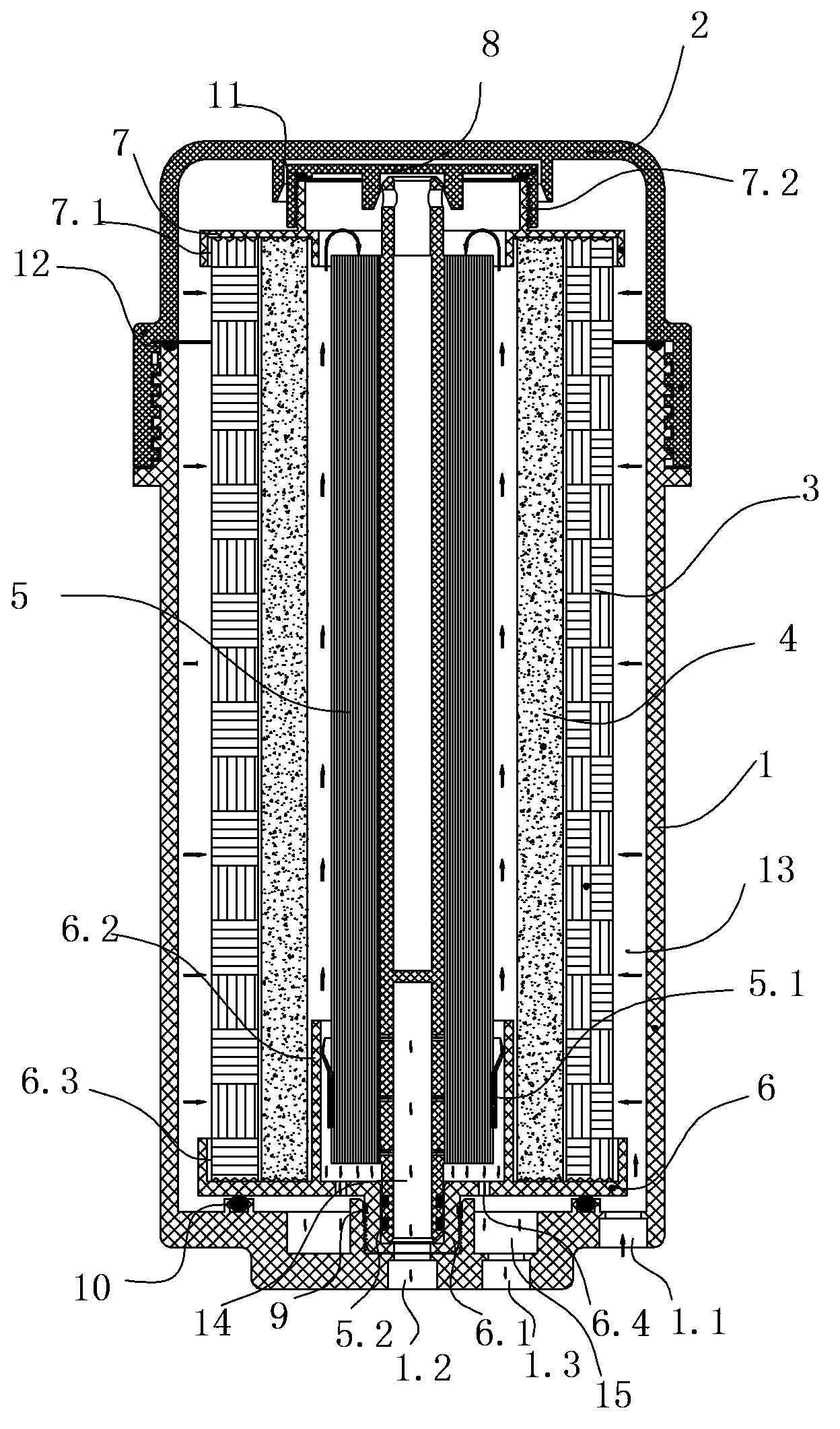

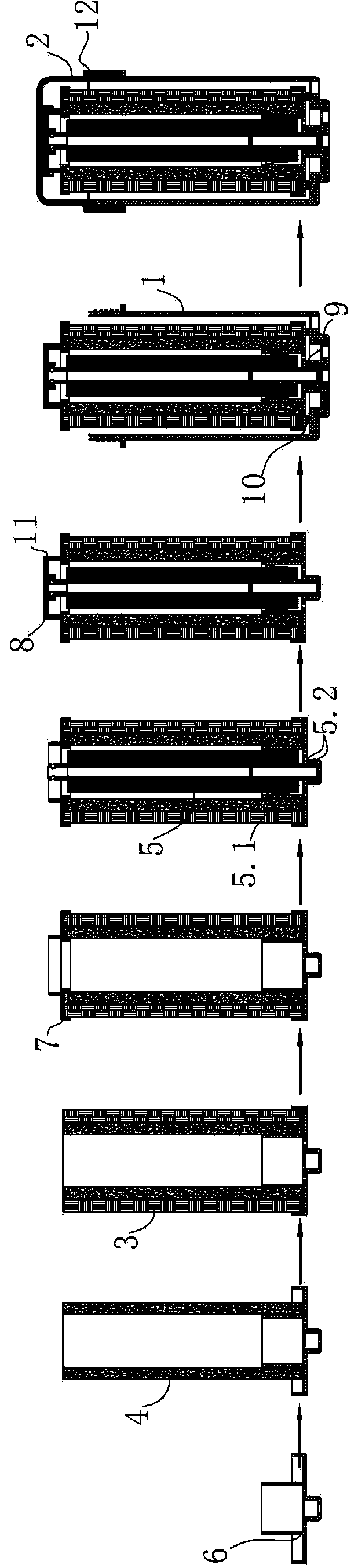

[0018] As shown in Figure 1, a composite filter element for a pure water machine includes a plastic filter shell 1, a filter cover 2, and a filter material with a coarse filtration system that is packaged in the filter shell 1 sequentially from the outside to the inside. And the RO membrane filter material 5 of the fine filtration system, the filter housing 1 is cylindrical, and the bottom of the filter housing 1 is provided with a source water inlet 1.1, a concentrated water outlet 1.3 and a pure water outlet 1.2 connected with the corresponding connecting pipe , wherein the pure water outlet 1.2 is set at the bottom center of the filter shell 1, the source water inlet 1.1 is set at one side of the bottom of the filter shell 1, and the concentrated water outlet 1.3 is set at the pure water outlet 1.2 and the source water inlet 1.1; a head cover 6 is fixedly connected to the inner wall of the bottom of the filter housing, and the lower end of the head cover is provided with a U...

Embodiment 2

[0022] The difference from Example 1 is that the filter material of the coarse filtration system is a two-layer combined structure of PP cotton 3 and activated carbon fiber from outside to inside.

Embodiment 3

[0024] The difference from Example 1 is that the filter material of the coarse filtration system is a three-layer combination structure of outer layer PP cotton, sintered activated carbon, and inner layer PP cotton from outside to inside, wherein the thickness of the outer layer PP cotton is 10um, and the inner layer PP cotton The thickness of the cotton is 5um.

[0025] The present invention only describes in detail the structure in which the filter material of the coarse filtration system and the RO membrane filter material of the fine filtration system are encased and packaged sequentially from the outside to the inside. Those skilled in the art can easily make the filter material of the coarse filtration system Arranged in reverse with the RO membrane filter material of the fine filtration system, a similar effect can also be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com