A deep red infrared-transmitting quartz glass plate and its preparation method

An infrared-transmitting and deep-red technology, which is applied in the field of deep-red infrared-transmitting quartz glass plate and its preparation, can solve the problems of poor infrared transmission performance and poor effect, and achieve the effect of good uniformity and low doping expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A dark red infrared-transmitting quartz glass plate, which uses high-purity quartz sand as a basic raw material by weight, and is equipped with trace element additives accounting for 6%-9.5% by weight of high-purity quartz sand, and uses SiO 2 The content is greater than 99.999%, the impurity content is less than 5ppm, and the high-purity quartz sand is 50-140 mesh.

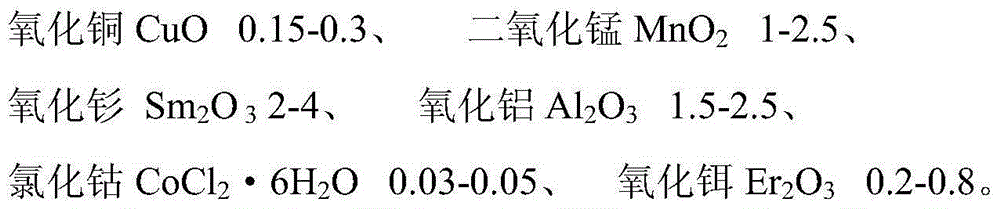

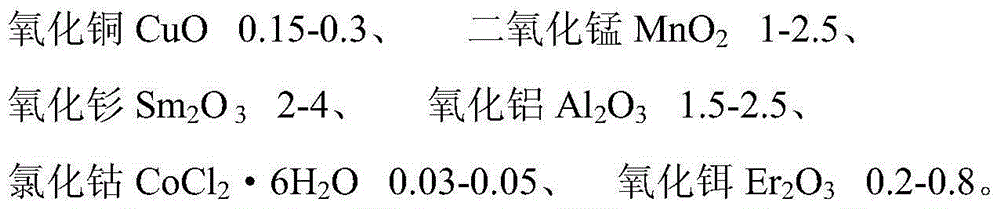

[0016] Wherein, the trace element additive is made up of the raw material of following weight ratio:

[0017]

[0018] The optimal weight of trace element additives is 8%-9.5% of high-purity quartz sand.

[0019] Trace element additive formula 1: copper oxide CuO 0.15, manganese dioxide MnO 2 1. Samarium oxide Sm 2 o 3 2. Aluminum oxide Al 2 o 3 1.5. Cobalt chloride CoCl 2 ·6H 2 O 0.03, erbium oxide Er 2 o 3 0.2.

[0020] Trace element additive formula 2: copper oxide CuO 0.2, manganese dioxide MnO 2 2. Samarium oxide Sm 2 o 3 3. Aluminum oxide Al 2 o 3 2. Cobalt chloride CoCl 2 ·...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com