A kind of integrated equipment for charging explosives and explosives

A technology for loading pressurized explosives and pyrotechnics, applied in offensive equipment, chemical industry, sustainable manufacturing/processing, etc., can solve problems such as low production efficiency, high production cost, and unguaranteed safety, and achieve work efficiency High, simple structure, reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

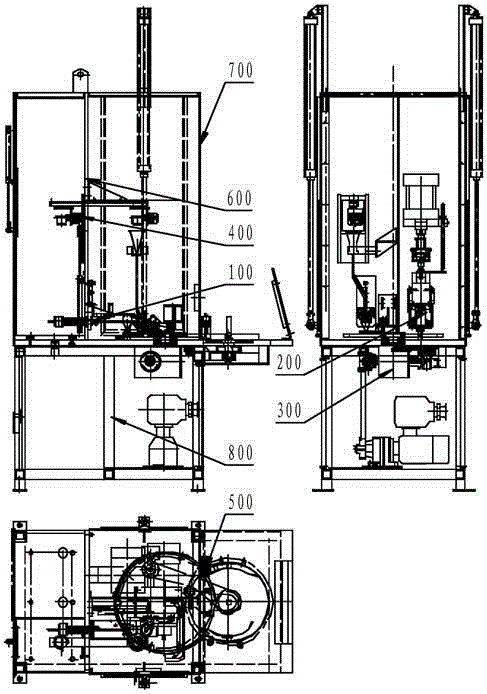

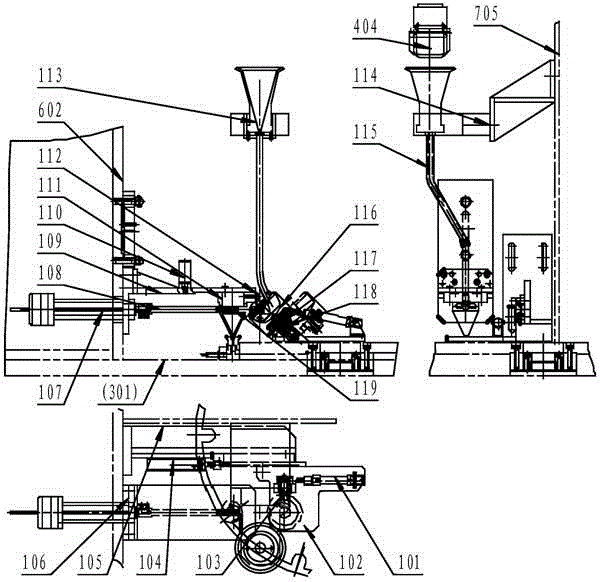

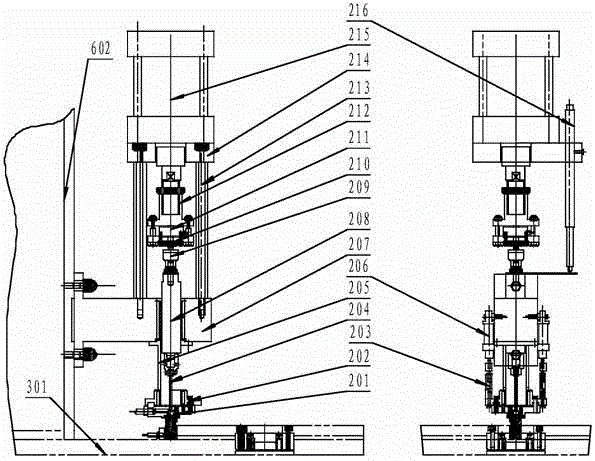

[0042] see Figure 1 to Figure 11 , this implementation provides a specific structure of an integrated equipment for loading and pressing explosives, including a frame 800, an upper bracket 600, a protective cover 700, a charge device 100, a medicine replenishing mechanism 400, a pressure mechanism 200, and a mold operation Mechanism 300, positive waste separation mechanism 500, electrical control system and gas circuit control system;

[0043] The table panel 301 of the mold operating mechanism 300 is installed on the upper plane of the frame 800, the upper bracket 600 is installed on the rear end of the upper plane of the table panel 301, the charge device 100 is installed on the lower left side of the front end of the upper bracket 600, and the medicine replenishing mechanism 400 is installed on The upper left of the front end of the upper bracket 600 is located directly above the charge device 100, the pressure mechanism 200 is installed on the right side of the front end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com