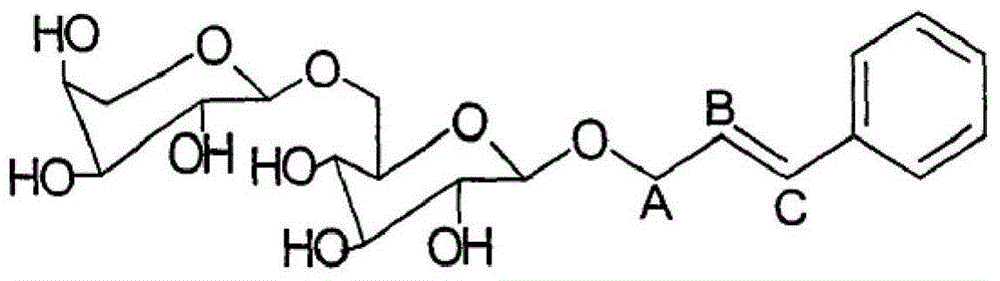

A method for extracting Roseville from rhodiola rosea

A crude extraction technology of rose bengal, applied in chemical instruments and methods, preparation of sugar derivatives, sugar derivatives, etc., can solve the problems of insufficient stability, low product purity, large amount of extractant, etc., and achieve less reagent consumption, High yield and purity in a short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Roseville extract from Rhodiola rosea, the steps are as follows:

[0023] 1) Using Rhodiola rosea as the raw material, reflux extraction twice with 65% ethanol solution 9 times the weight of the raw material, 2 hours each time, combine the extracts, concentrate the extracts under reduced pressure to 2 times the weight of the raw materials, centrifuge, and The clear liquid passes through the chromatographic column filled with D101 macroporous resin, the flow rate of the upper column is 1BV / h, and washed with water (the flow rate of water washing is 0.8BV / h) until the effluent is clear, first eluted with 20% ethanol solution, and then with 65% Elution with ethanol solution, collecting the eluate of 65% ethanol solution, concentrating under reduced pressure, and drying to obtain the crude extract;

[0024] 2) Use dichloromethane as the extractant to perform subcritical extraction on the crude extract. The injection volume of the extractant is 1.5 times the weight of the cr...

Embodiment 2

[0026] Roseville extract from Rhodiola rosea, the steps are as follows:

[0027] 1) Using Rhodiola Rosea as the raw material, reflux extraction with 65% ethanol solution 8 times the weight of the raw material for 3 times, 1 hour each time, combine the extracts, concentrate the extracts under reduced pressure to 2 times the weight of the raw materials, centrifuge, and The supernatant was passed through the chromatographic column filled with D101 macroporous resin, the flow rate of the upper column was 1.2BV / h, washed with water (the flow rate of water washing was 0.5BV / h) until the effluent was clear, first eluted with 20% ethanol solution, and then washed with 65 % ethanol solution for elution, collect the eluate of 65% ethanol solution, concentrate under reduced pressure, and dry to obtain the crude extract;

[0028] 2) Use dichloromethane as the extractant to perform subcritical extraction on the crude extract. The injection volume of the extractant is twice the weight of th...

Embodiment 3

[0030] Roseville extract from Rhodiola rosea, the steps are as follows:

[0031] 1) With Rhodiola rosea as the raw material, reflux extraction once with 70% ethanol solution 9 times the weight of the raw material, for 2 hours each time, concentrate the extract under reduced pressure to 2.5 times the weight of the raw material, centrifuge, and the supernatant through the filling For the chromatographic column with D101 macroporous resin, the flow rate of the upper column is 0.8BV / h, wash with water (the flow rate of water washing is 0.8BV / h) until the effluent is clear, first elute with 25% ethanol solution, and then wash with 70% ethanol solution Remove, collect the eluate of 70% ethanol solution, concentrate under reduced pressure, and obtain the crude extract after drying;

[0032] 2) Use dichloromethane as the extractant to perform subcritical extraction on the crude extract. The injection volume of the extractant is 1 times the weight of the crude extract. The extraction t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com