Ganoderma lucidum spore purification method

A technology of Ganoderma lucidum spores and Ganoderma lucidum spore powder, which is applied in the direction of using spores, biochemical equipment and methods, microorganisms, etc., can solve the problems of products not meeting quality requirements, long washing and soaking time, and high water temperature, and achieve maintenance Aromatic flavor, strong industrial applicability, and time-shortening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

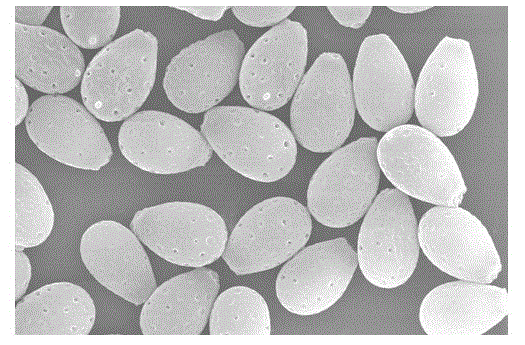

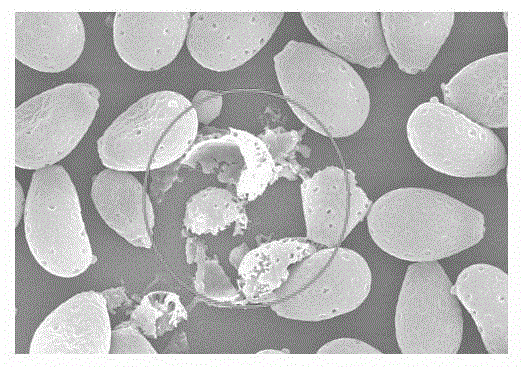

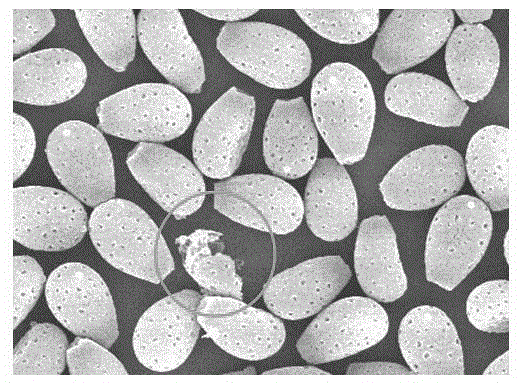

Image

Examples

Embodiment 1

[0037] Example 1 Low-temperature washing and high-speed centrifugal vacuum drying technology to purify Ganoderma lucidum spores

[0038] (1) Take 5 kg of newly harvested Ganoderma lucidum spore powder, pour it into a 400-mesh steel sieve twice, wash and filter in a low-temperature ice-water bath at 4°C, vibrate and sieve continuously, and discard the filter residue. This operation takes 10 minutes completed within.

[0039] (2) Put the frozen filtrate into the SS450 three-leg filter centrifuge for rapid dehydration, the centrifugal speed is 2000 r / min, and slowly adjust the supernatant discharge valve at the beginning to remove the supernatant and impurities smaller than the spore size, The supernatant just discharged is milky white gaseous water, and then turns into a transparent liquid; the centrifugation time is about 10 minutes, and when no gaseous water is discharged, it indicates that the dehydration process is completed; after shutting down the centrifuge, immediately t...

Embodiment 2

[0044] Example 2 Purification and treatment of Ganoderma lucidum spores by low-temperature washing and high-speed centrifugal vacuum drying technology

[0045] (1) Take 5 kg of newly harvested Ganoderma lucidum spore powder, pour it into a 400-mesh steel sieve twice, wash and filter in a low-temperature ice-water bath at 2°C, vibrate and sieve continuously, and discard the filter residue. This operation takes 10 minutes completed within.

[0046] (2) Put the frozen filtrate into the SS450 three-leg filter centrifuge for rapid dehydration, the centrifugal speed is 1000 r / min, and slowly adjust the supernatant discharge valve at the beginning to remove the supernatant and impurities smaller than the spore size, The supernatant just discharged is milky white gaseous water, and then turns into a transparent liquid; the centrifugation time is about 20 minutes, and when no gaseous water is discharged, it indicates that the dehydration process is completed; after shutting down the ce...

Embodiment 3

[0051] Example 3 Low-temperature washing and high-speed centrifugal vacuum drying technology to purify Ganoderma lucidum spores

[0052] (1) Take 5 kg of newly harvested Ganoderma lucidum spore powder, pour it into a 400-mesh steel sieve twice, wash and filter in a low-temperature ice-water bath at 6°C, vibrate and sieve continuously, and discard the filter residue. This operation takes 10 minutes completed within.

[0053] (2) Put the frozen filtrate into the SS450 three-leg filter centrifuge for rapid dehydration, the centrifugal speed is 1500 r / min, and slowly adjust the supernatant discharge valve at the beginning to remove the supernatant and impurities smaller than the spore size, The supernatant just discharged is milky white gaseous water, and then turns into a transparent liquid; the centrifugation time is about 15 minutes, and when no gaseous water is discharged, it indicates that the dehydration process is completed; after shutting down the centrifuge, immediately t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com