Advance integrated installing method of converter

An integral installation and converter technology, applied in the direction of manufacturing converters, etc., can solve the problems of delaying the installation start time of high-rise frame steel structures, increasing the cost of finished product protection measures or repairs, and failing to meet construction needs. duration, effectiveness of improving accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

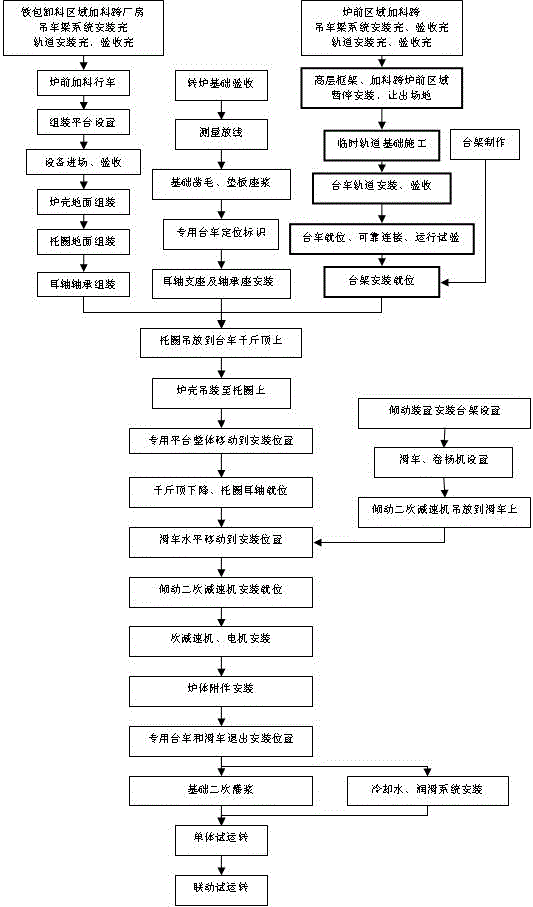

[0022] See figure 1 , the present invention comprises the following steps:

[0023] 1. The installation of the crane beam system across the factory building for charging in front of the furnace is completed, and the inspection and acceptance of the inner-span driving track are completed;

[0024] 2. Suspend the operation of the large crane used to install the feeding span and the high-rise frame steel structure in the feeding span site in front of the furnace, exit the area that needs to be used for converter installation, and clean up the components and other objects accumulated on the ground;

[0025] 3. Level and compact the site, handle the foundation according to the bearing capacity of the foundation after checking, add steel billets or thick steel plates, and lay temporary tracks on it according to the elevation and gauge of the trolley tracks;

[0026] 4. Hang the two ladle cars on the temporary track, and remove the anti-collision devices of the two workshops, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com