Common hot-rolled steel plate with high strength and yield ratio and manufacturing method thereof

A hot-rolled steel sheet and a manufacturing method are applied in the field of high-strength-yield-ratio ordinary hot-rolled steel sheets and their manufacturing fields to achieve the effect of improving the strength-yield ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

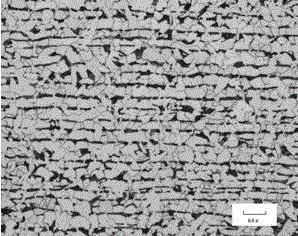

Embodiment 1

[0038] The chemical composition of SS400 high-strength and yield-ratio ordinary hot-rolled steel plate with a thickness of 18 mm is: C: 0.15%, Si: 0.22%, Mn: 0.71%, P: 0.013%, S: 0.003%, B: 0.0015 %, others are Fe and residual elements. The test results of its mechanical properties show that the yield strength is 240MPa, the tensile strength is 450MPa, the elongation is 29%, and the strength-to-yield ratio is 1.875.

[0039] The production method of the SS400 high-strength high-yield-ratio ordinary hot-rolled steel plate with a thickness of 18mm provided by the present invention has a process flow of: converter smelting→LF furnace refining→continuous casting→slab heating→rolling→controlled cooling→finishing, including the following step:

[0040] 1. Converter smelting

[0041] Add 102 tons of molten iron and 18 tons of steel scrap into a converter with a nominal capacity of 120 tons. The temperature of the molten iron is 1249°C. The chemical composition in terms of mass perc...

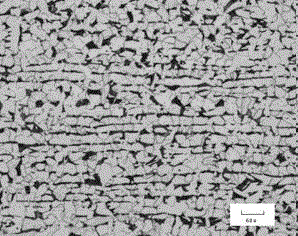

Embodiment 2

[0063] The chemical composition of SS400 high-strength and yield-ratio ordinary hot-rolled steel plate with a thickness of 40 mm is: C: 0.22%, Si: 0.24%, Mn: 0.87%, P: 0.016%, S: 0.010%, B: 0.0020 %, others are Fe and residual elements. The test results of its mechanical properties show that the yield strength is 255MPa, the tensile strength is 480MPa, the elongation is 28%, and the strength-to-yield ratio is 1.882.

[0064] The production method of the SS400 high-strength high-yield-ratio ordinary hot-rolled steel plate with a thickness of 40mm provided by the present invention has a process flow of: converter smelting→LF furnace refining→continuous casting→slab heating→rolling→controlled cooling→finishing, including the following step:

[0065] 1. Converter smelting

[0066] Add 98 tons of molten iron and 17 tons of steel scrap into a converter with a nominal capacity of 120 tons. The temperature of the molten iron is 1246°C. The chemical composition in terms of mass perce...

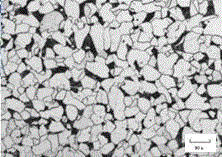

Embodiment 3

[0087] The chemical composition of Q235B high-strength and yield-ratio ordinary hot-rolled steel plate with a thickness of 12mm is: C: 0.12%, Si: 0.15%, Mn: 0.33%, P: 0.0213%, S: 0.018%, B: 0.0010 %, others are Fe and residual elements. The test results of its mechanical properties show that the yield strength is 235MPa, the tensile strength is 410MPa, the elongation is 33%, and the strength-to-yield ratio is 1.745.

[0088] The production method of the Q235B high-strength high-yield-ratio ordinary hot-rolled steel plate with a thickness of 12mm provided by the present invention has a process flow of: converter smelting→LF furnace refining→continuous casting→slab heating→rolling→controlled cooling→finishing, including the following step:

[0089] 1. Converter smelting

[0090] Add 100 tons of molten iron and 20 tons of steel scrap into a converter with a nominal capacity of 120 tons. The temperature of the molten iron is 1250°C. The chemical composition in terms of mass perc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com