Heat shaping machine

A heat-setting machine and heating box technology, applied in heating/cooling fabrics, textiles and papermaking, fabric surface trimming, etc., can solve the problems of heat waste, large pollution, high cost, and achieve convenient use, uniform temperature, and heat-setting effects. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

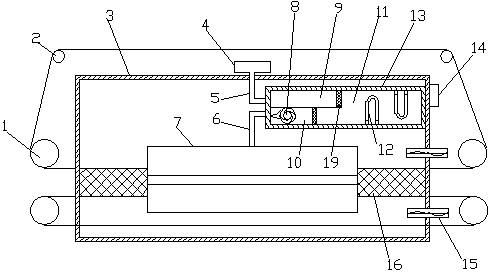

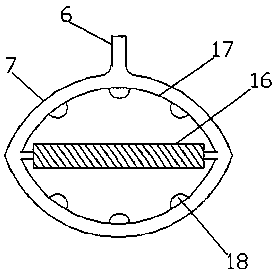

[0013] to combine figure 1 and figure 2 A kind of heat-setting machine shown, comprises insulation housing 3, heating box 13 and annular cover 7, is characterized in that, described heating box 13 is arranged in insulation housing 3, and heating box 13 surface layer is provided with insulation material, One side of the heating box 13 is provided with a suction pipe 5 and a blowing pipe 6, and one end of the suction pipe 5 runs through the heat preservation shell 3 and is connected with the suction fan 4, and the heating box 13 is provided with an upper air chamber 9, The heating chamber 11 and the lower air chamber 10, the upper air chamber 9 communicates with the suction pipe 5, a filter plate 19 is arranged between the upper air chamber 9 and the heating chamber 11, and the heating chamber 11 is provided with two U type heat source 12, the space in the lower air chamber 10 is smaller than the upper air chamber 9, and the lower air chamber 10 is provided with a blower 8, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com