An active covering system and method for in-situ controlling the release of nitrogen and phosphorus from surface water sediment

A sediment, nitrogen and phosphorus technology, applied in chemical instruments and methods, water/sludge/sewage treatment, river regulation, etc., can solve the problems of slow fixation rate, unsatisfactory efficiency, and reduced effect, so as to reduce the bottom Sludge nitrogen and phosphorus release, high immobilization efficiency and fast immobilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

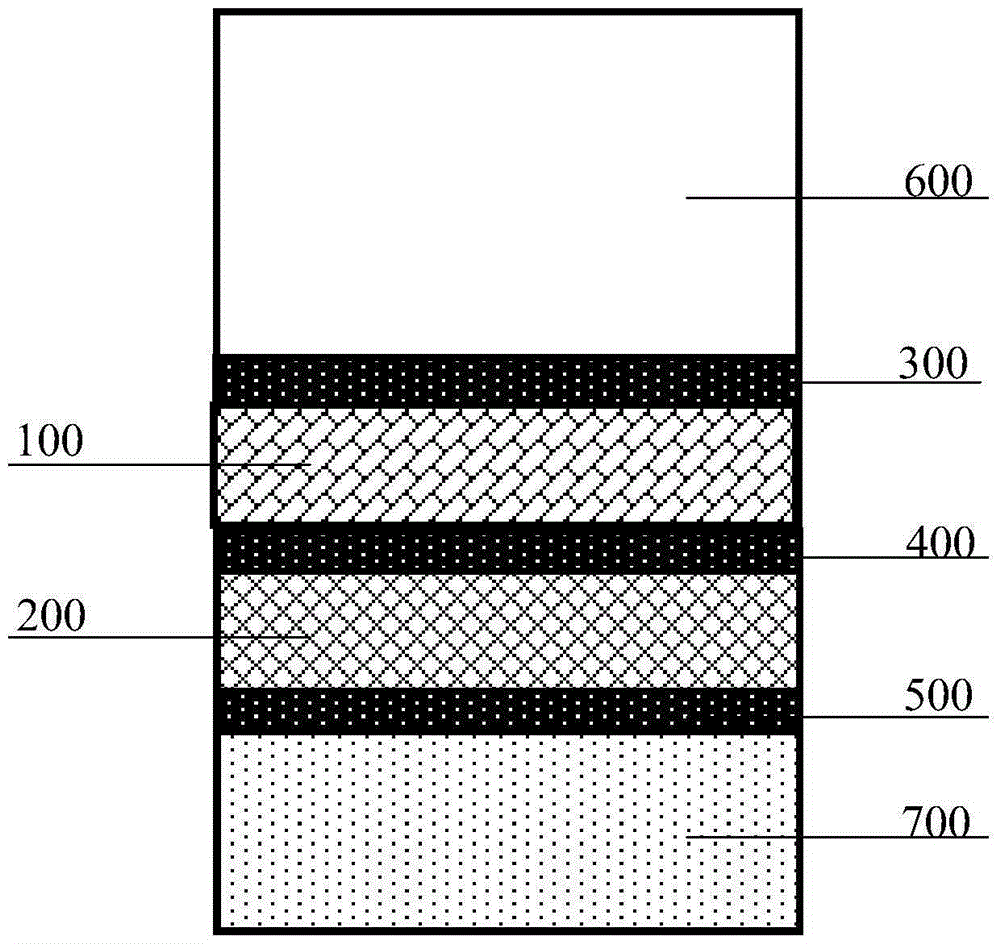

Method used

Image

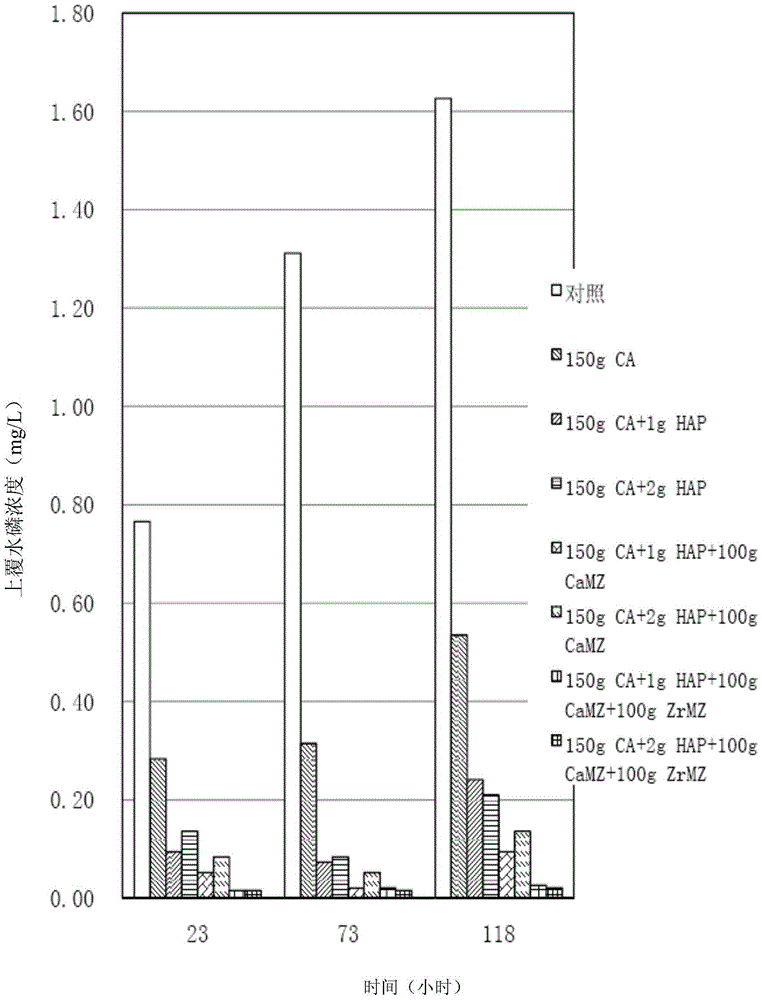

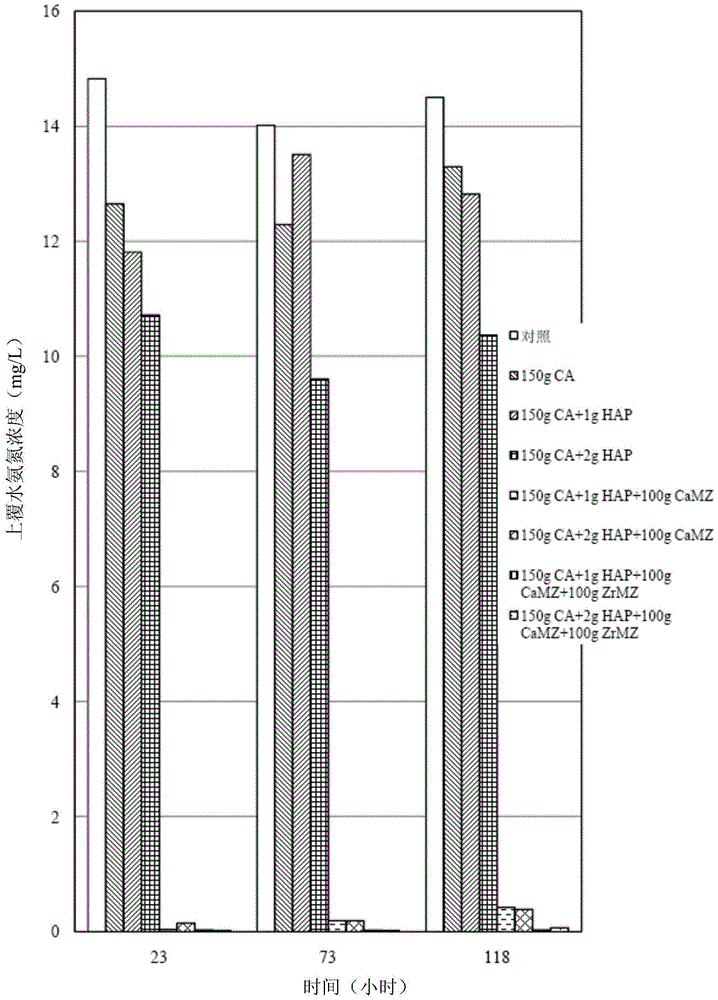

Examples

Embodiment 1

[0029] Firstly, prepare various sediment active covering materials.

[0030] 1. Synthesis of hydroxyapatite (abbreviated as HAP) by solution precipitation method. 50mL concentration of 1mol / L Ca(NO 3 ) 2 solution and 30mL concentration of 1mol / L (NH 4 ) 2 HPO 4The solution is mixed with 0.8mol / LNH 3 OH solution to adjust the pH to 9, then place the mixture in a shaker, shake at a speed of 150 rpm for 48 hours, take the precipitate and wash it to neutral, dry it to obtain apatite, and then crush it into a particle size of 200 mesh particles. Repeat the above process 4 times, and collect all the apatite samples for later use.

[0031] 2. Preparation of calcium-modified zeolite (abbreviated as CaMZ). Prepare Ca with a concentration of 1mol / L 2+ Solution; Weigh the natural zeolite with a particle size of over 80 mesh and place it in a container, then pipette Ca according to the liquid-solid ratio of 5mL / g 2+ The solution is fully mixed with the natural zeolite; after 40 ...

Embodiment 2

[0041] 1. Synthesis of hydroxyapatite (abbreviated as HAP) by solution precipitation method. 50mL concentration of 1mol / L Ca(NO 3 ) 2 solution and 30mL concentration of 1mol / L (NH 4 ) 2 HPO 4 The solution is mixed with 0.8mol / LNH 3 OH solution to adjust the pH to 9, then place the mixture in a shaker, shake at a speed of 150 rpm for 48 hours, take the precipitate and wash it to neutral, dry it to obtain apatite, and then crush it into a particle size of 200 mesh particles. Repeat the above process 4 times, and collect all the apatite samples for later use.

[0042] Preparation of calcium-modified zeolite (abbreviated as CaMZ). Prepare Ca with a concentration of 1mol / L 2+ solution (calcium nitrate or calcium chloride); take the natural zeolite with a particle size of over 80 mesh and place it in a container, then pipette the Ca 2+ The solution is fully mixed with the natural zeolite; after 40 hours of reaction, the solid-liquid separation, cleaning and drying can be ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com