Mechanical flushing squatting pan

A technology for squatting toilets and flushing, applied in water supply devices, flushing equipment with water tanks, buildings, etc., can solve the problems of potential safety hazards, non-flushing toilets, poor toilet environment, etc., achieve compact structure, no potential safety hazards, and improve The effect of degrees of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

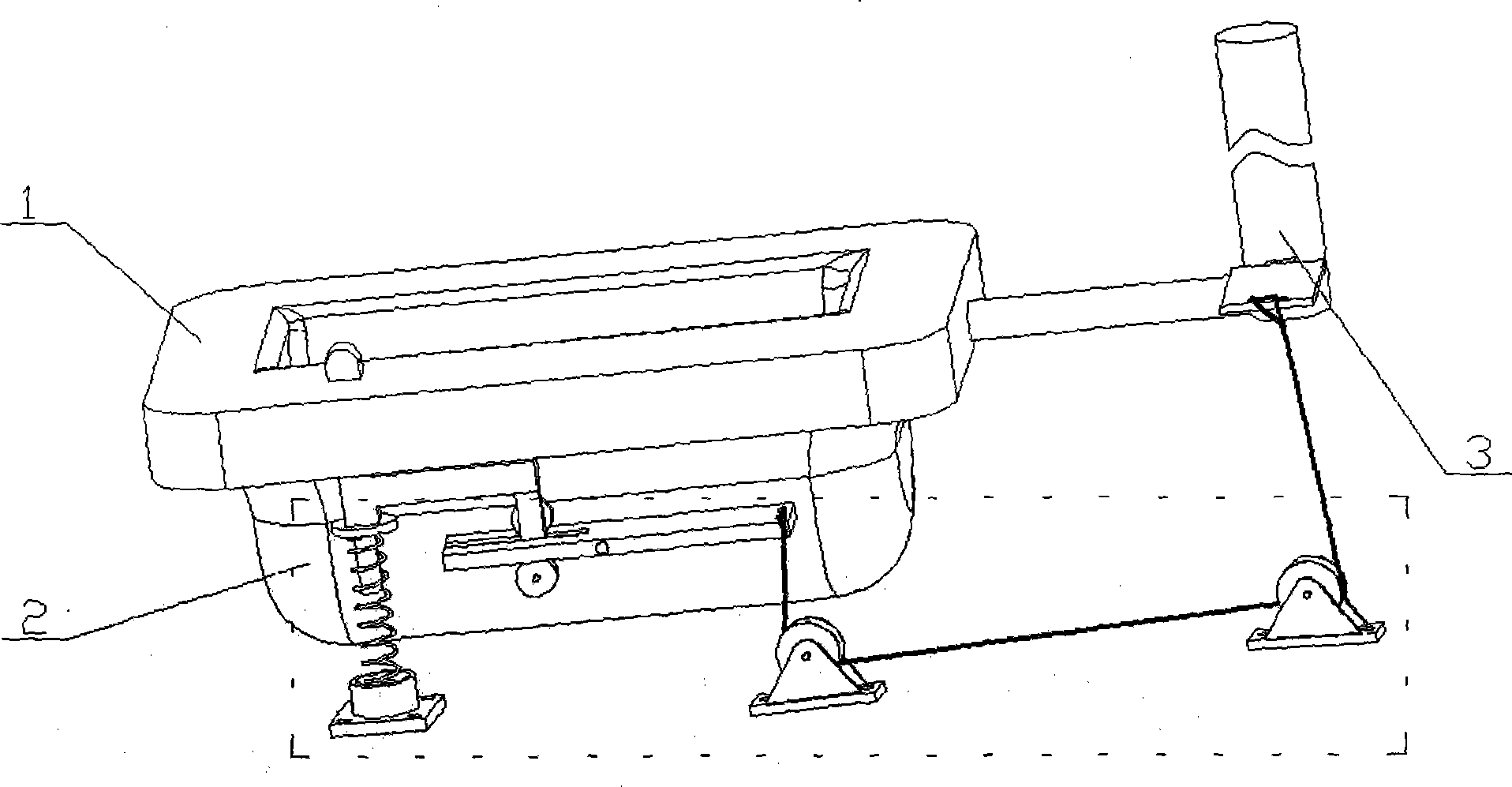

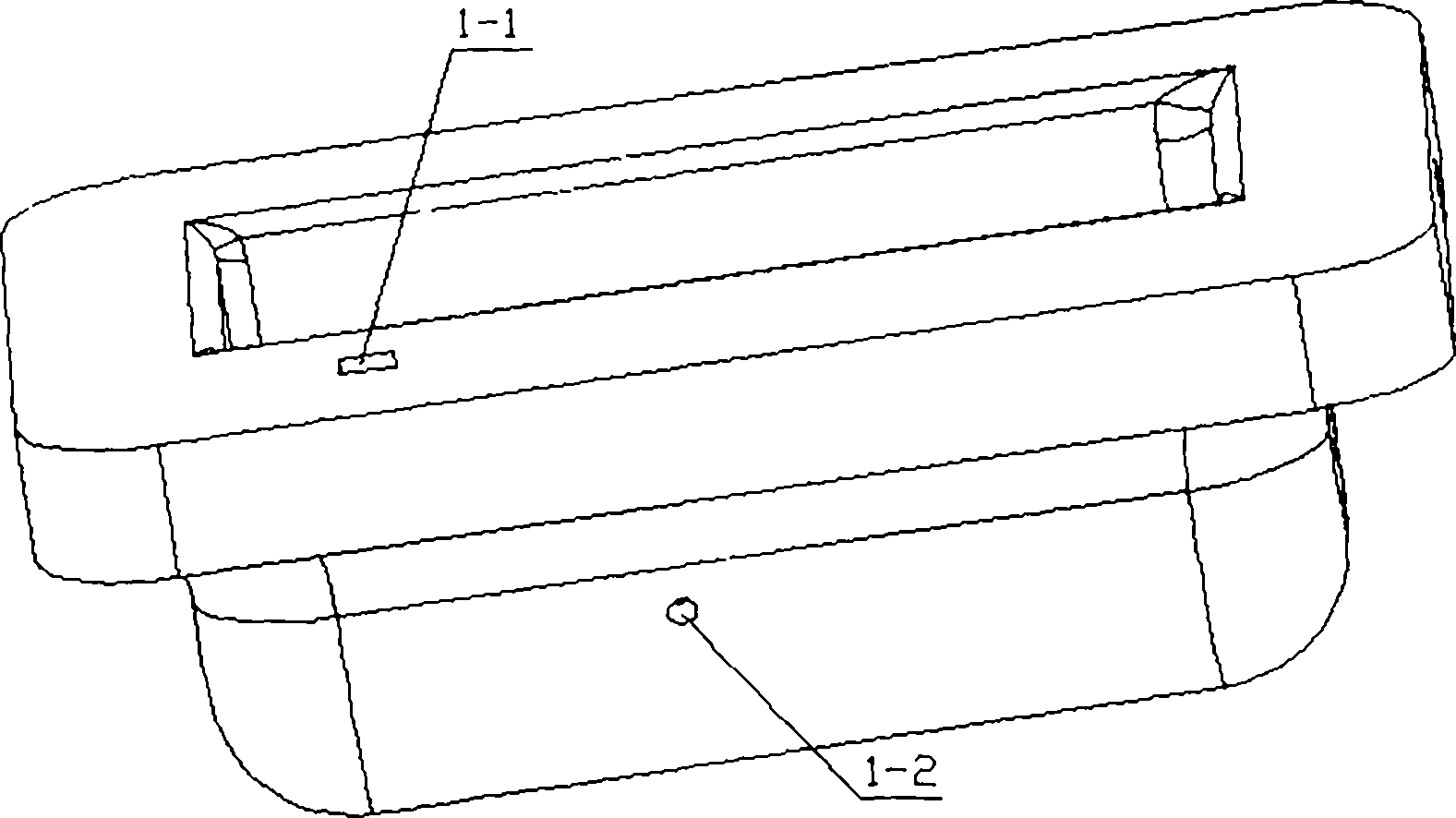

[0021] like figure 1 , image 3 As shown, the squatting pan includes a bedpan 1 , a transmission part 2 and a flushing part 3 . The bedpan is provided with a rectangular through hole 1-1 and a threaded blind hole 1-2, and the end of the flushing pedal 3-1 of the flushing component 3 is provided with a fixing hole for fixing a steel wire. The bedpan 1 and the flushing part 3 can directly use existing products on the current market, and process the rectangular hole through hole 1-1 and the threaded blind hole 1-2 at suitable positions on the surface and side of the bedpan 1, while the flushing part 3 only needs The end of the selected product can be processed with two through holes. In order to facilitate the fixing of steel rope 2-8 wire ends, at least two steel wire clips are required.

specific Embodiment approach 2

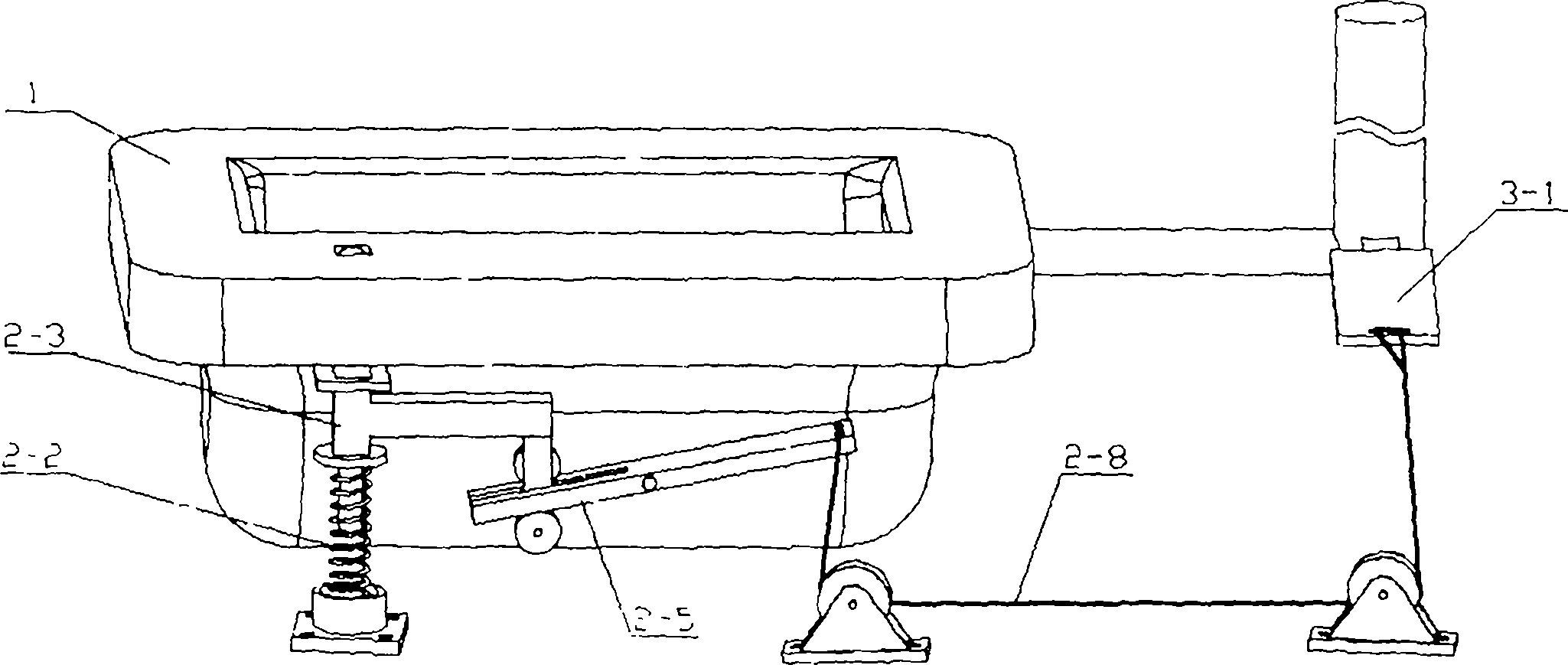

[0022] like Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 As shown, the transmission part 2 includes a spring base 2-1, a return spring 2-2, a moving rod 2-3, a roller one 2-4, a roller two 2-5, a rotating plate 2-6, and a rotating shaft 2-10 , pulley one 2-7, pulley two 2-9 and steel rope 2-8. Return spring 2-2 is vertically fixed in spring base 2-1, and spring base 2-1 is installed on the ground. The moving rod 2-3 includes the top 2-3-1 of the moving rod, the limit plate 2-3-2, the spring baffle 2-3-3, the spring guide rod 2-3-4, and the middle part of the moving rod 2-3-5 , moving rod tail 2-3-6 and two roller shafts 2-3-7, 2-3-8; moving rod top 2-3-1 section is rectangular, and it slides with the rectangular through hole 1-1 on the bedpan Cooperate; the limit plate 2-3-2 cooperates with the lower end face of the bedpan, and limits the maximum height that the moving rod 2-3 rises under the restoring force of the return spring 2-2; the spring baffle plate 2...

specific Embodiment approach 3

[0024] figure 1 , Figure 9 As shown, since the installation ground of the bedpan is mostly cement floor, when installing the flushing device, according to the actual space position of the bedpan 1 and the installation position of the flushing device 3, the spring base can be installed first by using expansion screws or anchor bolts 2-1 and two pulleys 2-7, 2-9. For the convenience of installation, the spring base and the two pulleys should be installed on the same plane as far as possible. Need to be decided by the position of bedpan 1 and flush pedal 3-1. After spring base and two pulleys are installed, other parts are installed again, and steel rope 2-8 is then installed at last, and steel rope will be adjusted to suitable length when steel rope 2-8 is installed. When the steel rope is installed, the two pulleys and the steel rope should be protected by round pipes and U-shaped pipes, etc., so that the pulleys and the steel rope can move freely without being buried. Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com