Wave web with variable cross section

A technology of wavy webs and variable cross-sections, applied to structural elements, building components, and elongated structural components for load-bearing, etc., can solve the problems of insufficient use of materials, constant wave height and wave distance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] 1. Wave web 2. Flange.

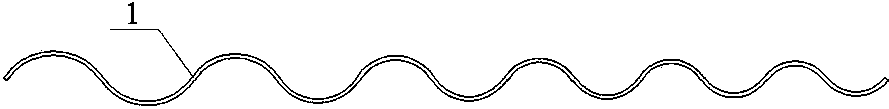

[0020] exist figure 1 and figure 2 In the shown embodiment: the corrugated web 1 is periodically repeated wavy along the length direction, and while the corrugated web 1 periodically repeats along the longitudinal direction, the wave height and wave pitch of the corrugated web 1 are uniform. slowing shrieking.

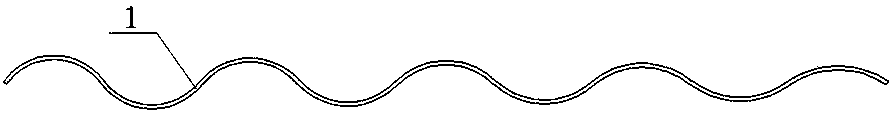

[0021] exist image 3 In the shown embodiment: the corrugated web 1 is a periodically repeated wave shape along the length direction, and while the wave shape of the corrugated web 1 is periodically repeated along the length direction, the wave height of the corrugated web 1 gradually decreases, But the pitch remains unchanged.

[0022] exist Figure 4 and Figure 5 In the shown embodiment: the wave web 1 fixes a piece of wing plate 2 on both sides along the width direction to form an "I"-shaped member, and the board surfaces of the two wing plates 2 are parallel to each other and are perpendicular to the width of the wave web 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com