Construction device for in-situ maintenance or extension of highway tunnel

A technology for construction equipment and road tunnels, applied in tunnels, mining equipment, earthwork drilling and mining, etc., can solve traffic impact and other problems, achieve the effect of reducing traffic pressure, reducing adverse effects, and increasing construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

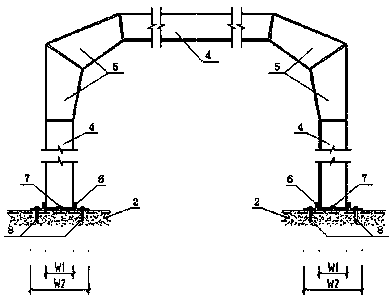

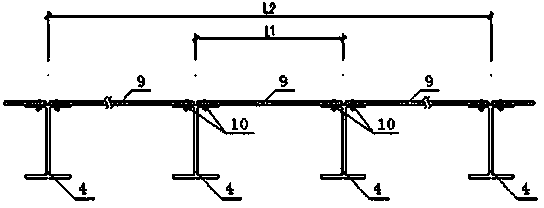

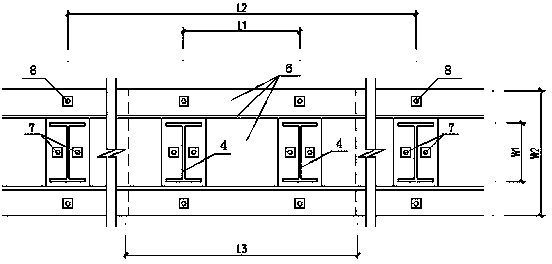

[0018] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

[0019] refer to Figure 1 to Figure 4 , the invention relates to a construction device for in-situ maintenance or expansion of a highway tunnel, comprising a steel shield for in-situ maintenance or in-situ expansion of the tunnel, the steel shield comprising a portal steel frame, a skin steel plate and The chute is composed together, and the geometric size of the steel shield should be comprehensively determined after optimization comparison and selection based on the clearance in the existing tunnel, the clearance required for the passage of traffic vehicles, and the clearance required for the operation of construction machinery.

[0020] The steel beams and steel columns of the above-mentioned portal steel frame are H-shaped steel; and the beam-column joints ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com