Coal roadway rapid excavation temporary supporting system and supporting method applying same

A temporary support and coal roadway technology, which is applied in the direction of earth drilling, mine roof support, mining equipment, etc., can solve the problems of structure and operation convenience, safety restrictions, limited support distance, complex structure, etc., and achieve coal mining The effect of high tunneling efficiency, long support distance and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

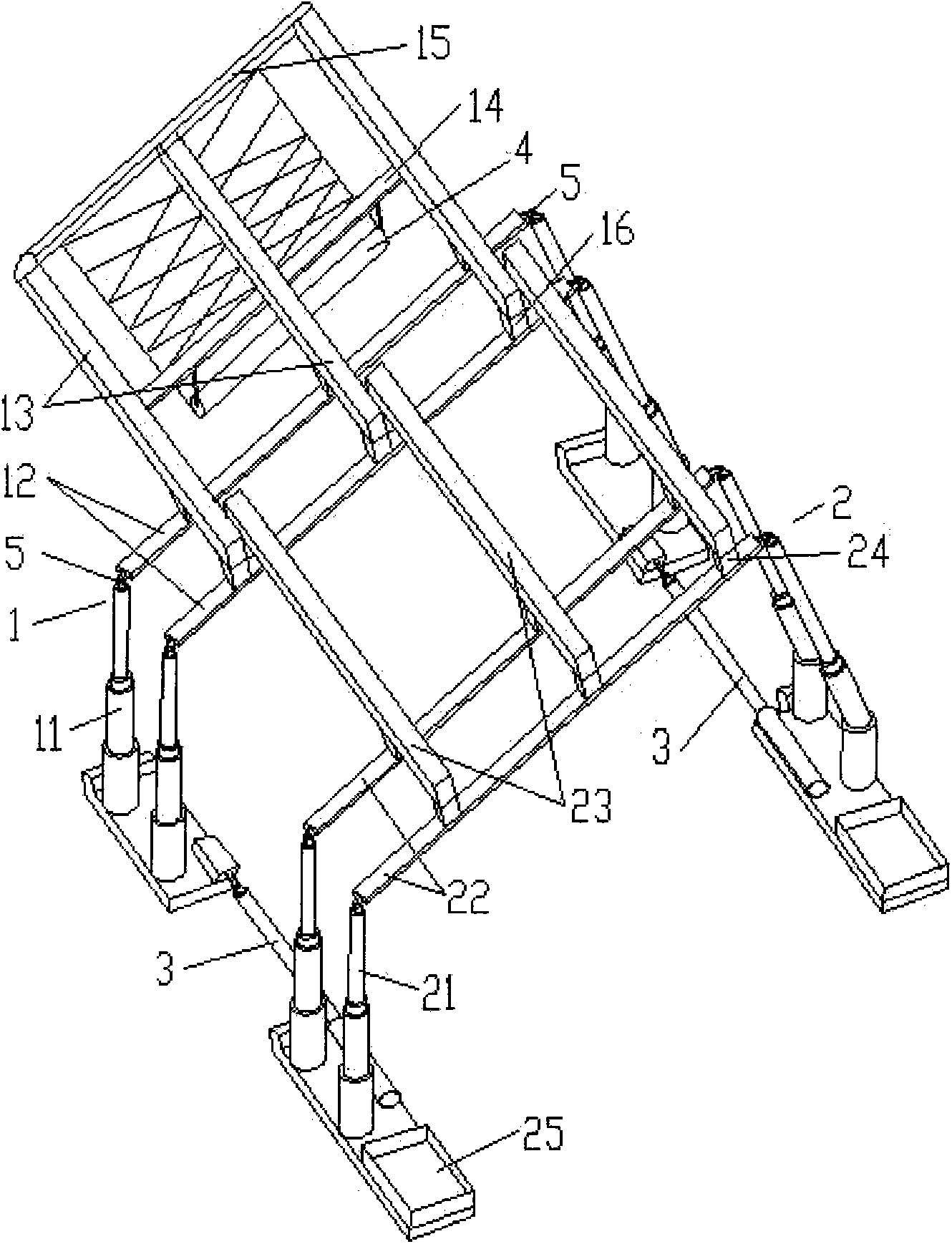

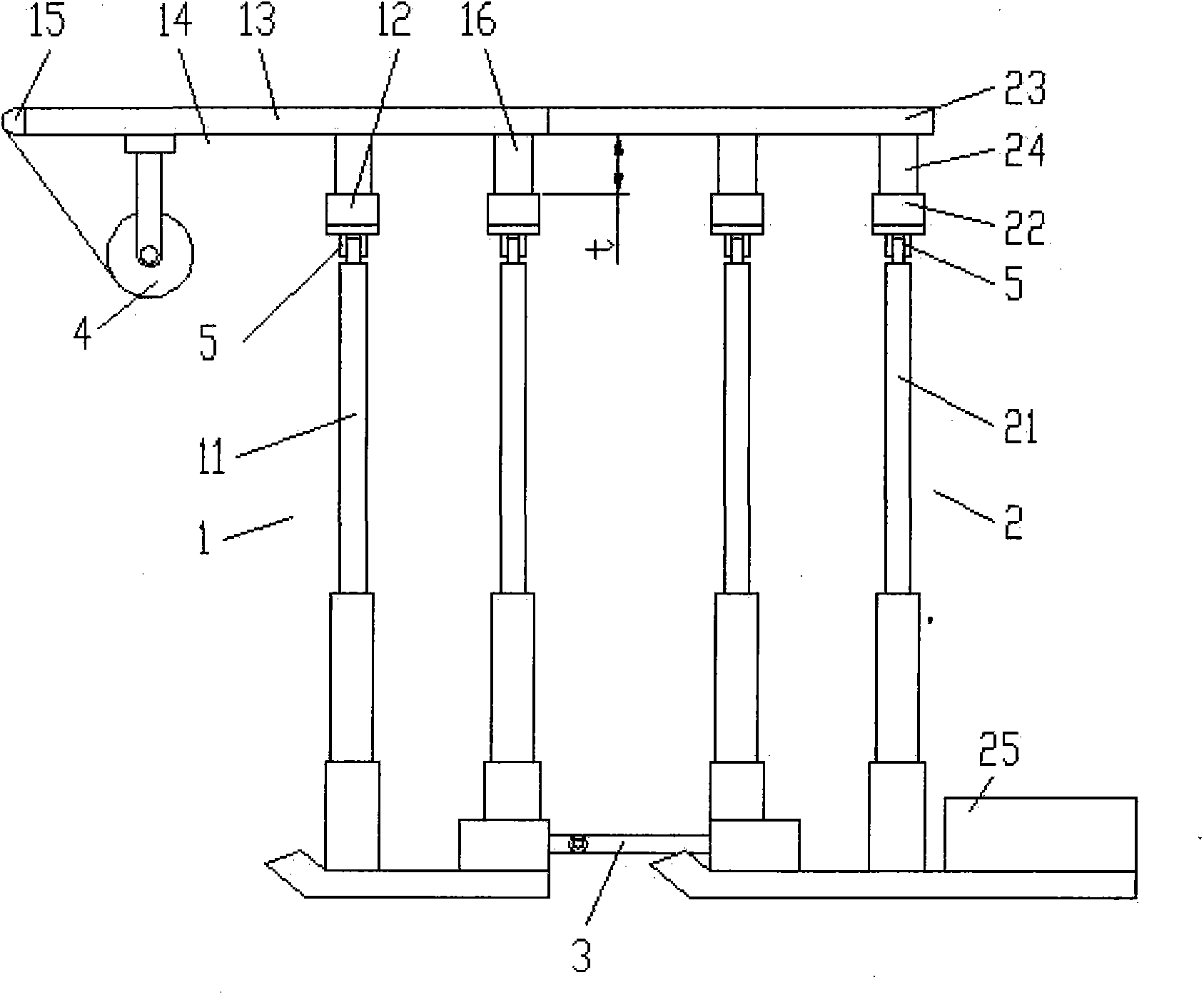

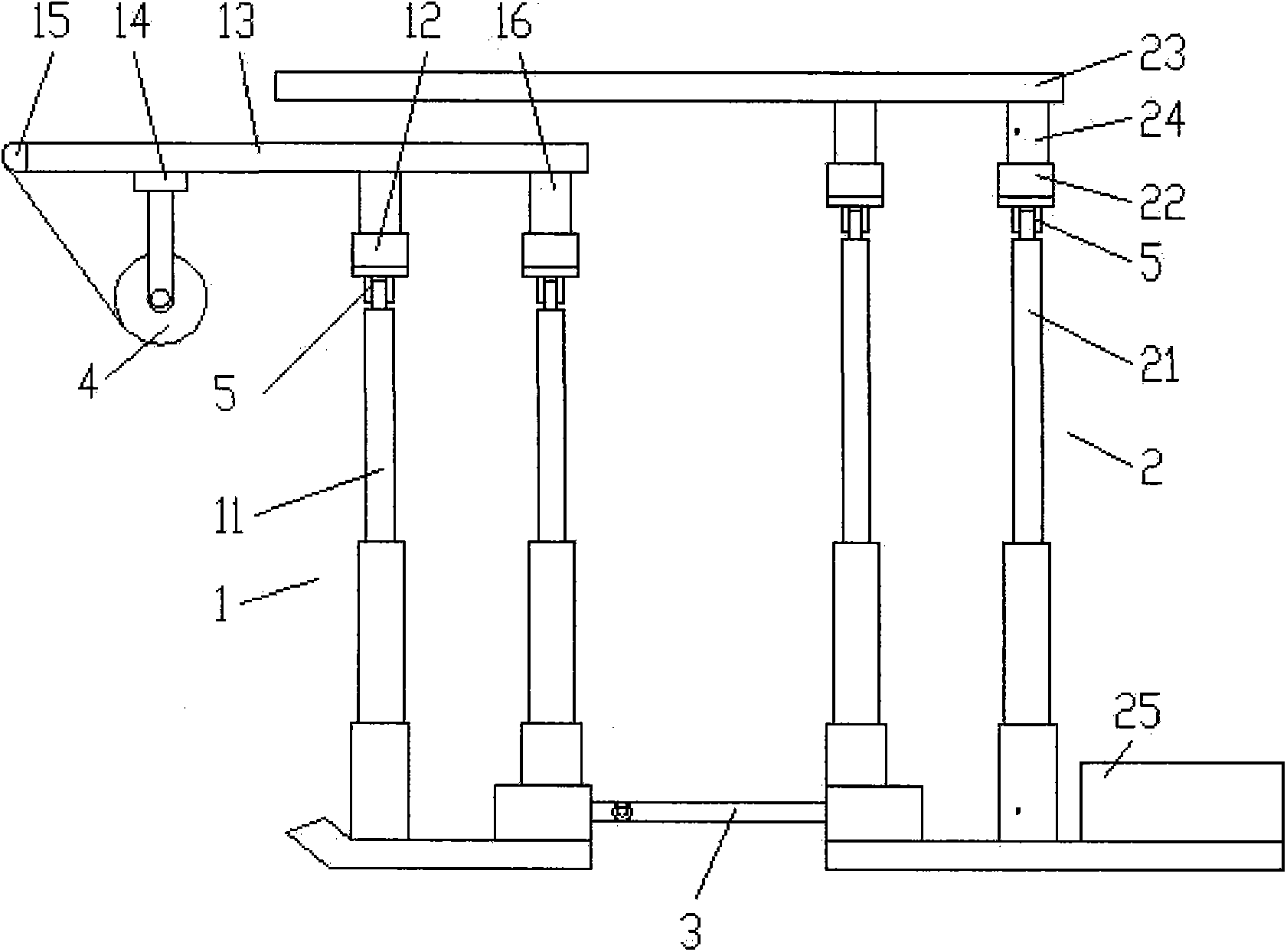

[0033] Example 1 see figure 1 , figure 2 , image 3 , Figure 4 , a temporary support system for coal roadway rapid excavation, including two first hydraulic lifting support frame 1 and second hydraulic lifting support frame 2 which are independent of each other and form a front and rear position relationship, the first hydraulic lifting support frame 1 and the second hydraulic lifting support frame Two hydraulic lift support frame 2 is provided with the front probe support beam part that can form the support section of double support to the roof of coal roadway, the base of the first hydraulic lift support frame 1 and the second hydraulic lift support frame 2 are all In the shape of a sliding shoe, a propulsion hydraulic cylinder 3 is provided between the first hydraulic lifting support frame 1 and the second hydraulic lifting support frame 2; a storage space for storing metal mesh rolls is provided on the first hydraulic lifting support frame 1 Roller 4, when the first hyd...

Embodiment 2

[0043] Example 2 see figure 1 , figure 2 , image 3 , Figure 4 , a coal roadway rapid tunneling temporary support method, the method uses the coal roadway rapid tunneling temporary support system described in embodiment 1 to implement the temporary support of coal roadway excavation, comprising the following steps,

[0044] In the first step, the temporary support system is placed in a coal roadway with a set depth of excavation, and the first probing beam 13 of the first hydraulic lifting support frame 1 and the front beam 13 of the second hydraulic lifting support frame 2 are placed A part of the second front probe beam 23 extends below the roof of the coal roadway;

[0045] In the second step, the wire mesh stored on the storage roller 4 of the first hydraulic lift support frame 1 is pulled out upwards, and the first hydraulic lift support frame 1 of the wire mesh is moved toward the second hydraulic lift support frame. The frame 2 direction is laid on the top surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com