Connecting assembly for dual universal half shafts of vehicle driving axle

A vehicle drive and assembly technology, which is applied to axles, vehicle components, wheels, etc., can solve the problems of affecting the service life of vehicle drive axles, high manufacturing costs, and failure to eliminate the overall structure, so as to achieve a compact internal structure. The effect of low cost and shortened overall length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

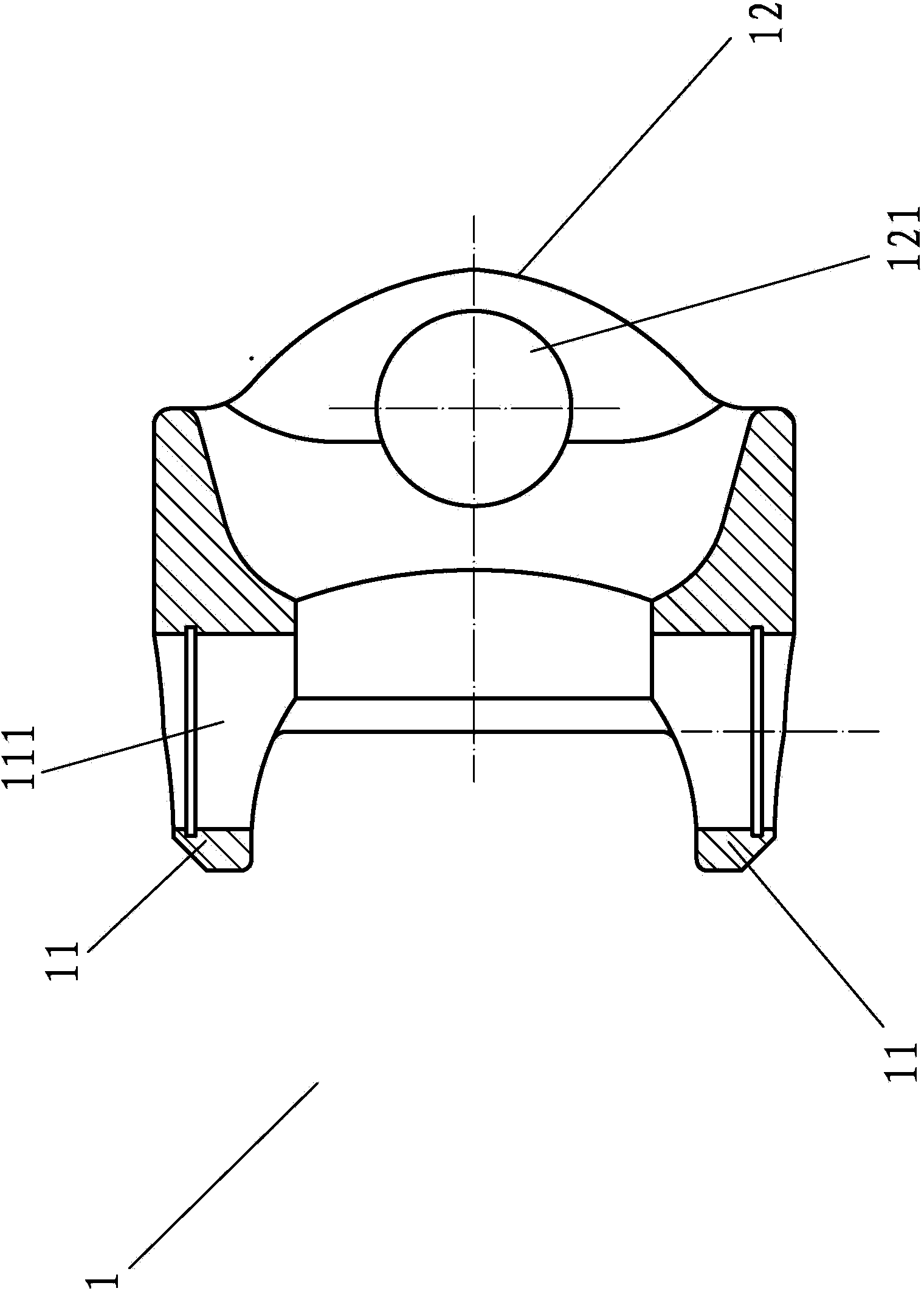

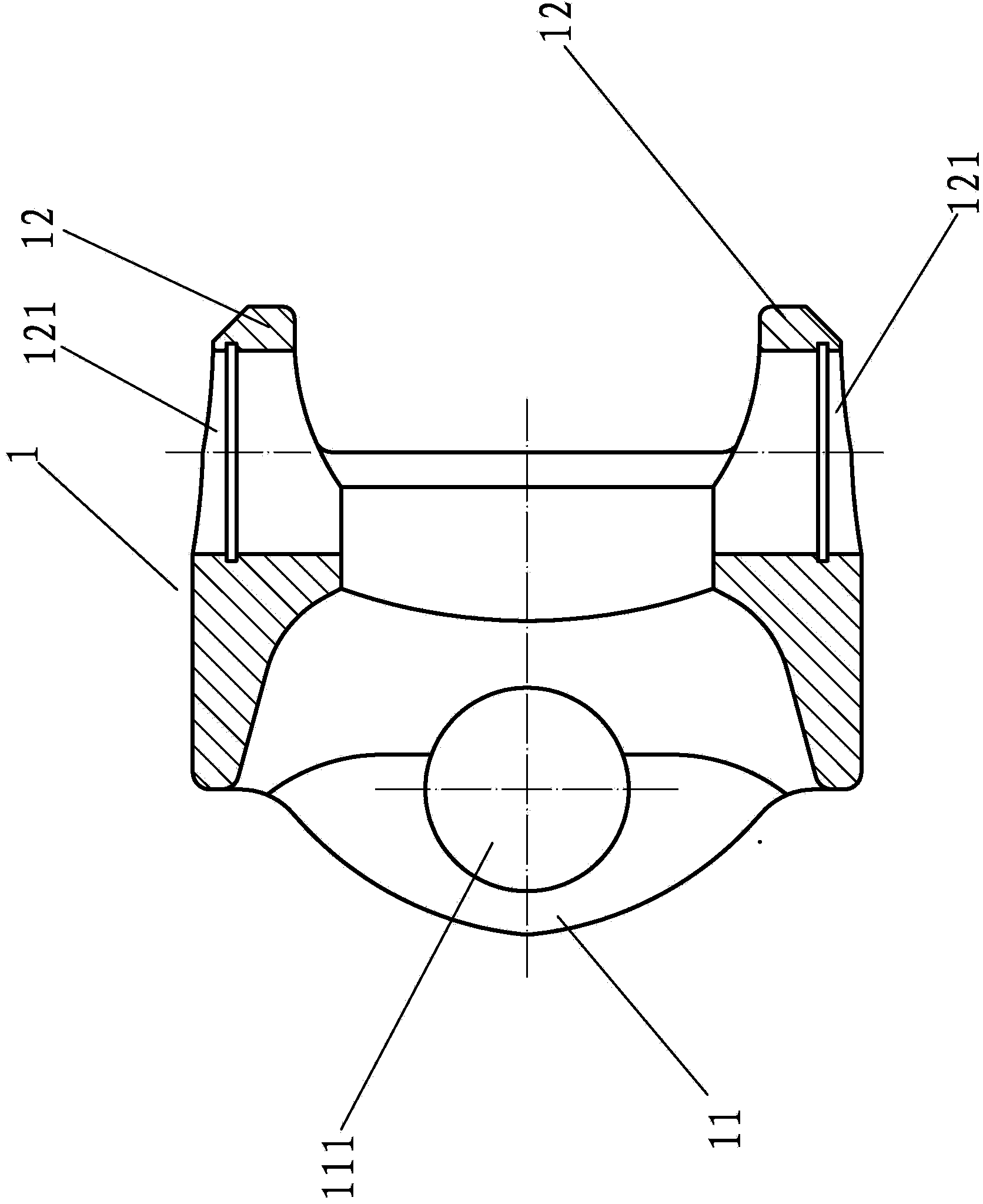

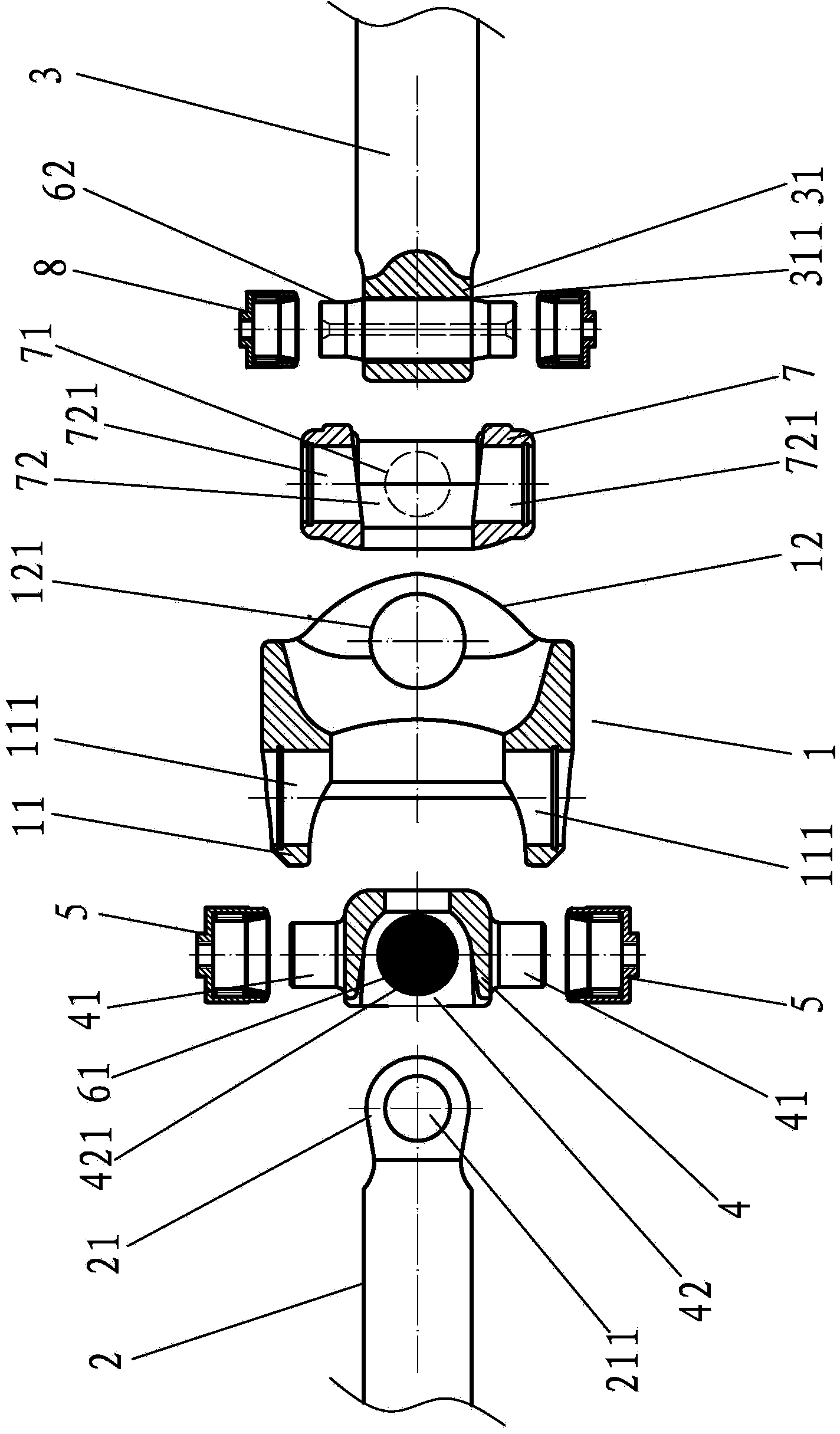

[0030] A connection assembly of a double universal joint half shaft of a vehicle drive axle of the present invention, such as figure 1 , 2 As shown, it includes a connecting fork 1, the connecting fork 1 is a hollow columnar structure with open ends, and a pair of opposite first fork ears 11 are protruded on the first end surface of the connecting fork 1 in the axial direction. The first fork ear 11 is provided with a part of which is distributed at the first fork ear 11, and the other part is distributed at the first installation hole 111 at the connection fork 1, and the axial second end surface of the connection fork 1 is protruded with a For the second fork ears 12 that are oppositely arranged, two second fork ears 12 are all provided with a part of which is distributed at the second fork ears 12, and the other part is distributed at the second mounting holes 121 at the connecting fork 12 places; The center line between the fork ears 11 is perpendicular to the center line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com