Mixed refrigerant refrigeration circulating system

A technology of mixed working fluid and circulation system, which is applied in refrigerators, refrigeration and liquefaction, and irreversible cycle compressors, etc., can solve the problems of increasing the irreversible loss of the system, failing to achieve high-efficiency low-temperature refrigeration, reducing compressor efficiency, etc. The effect of power consumption, increasing back pressure, and increasing suction pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

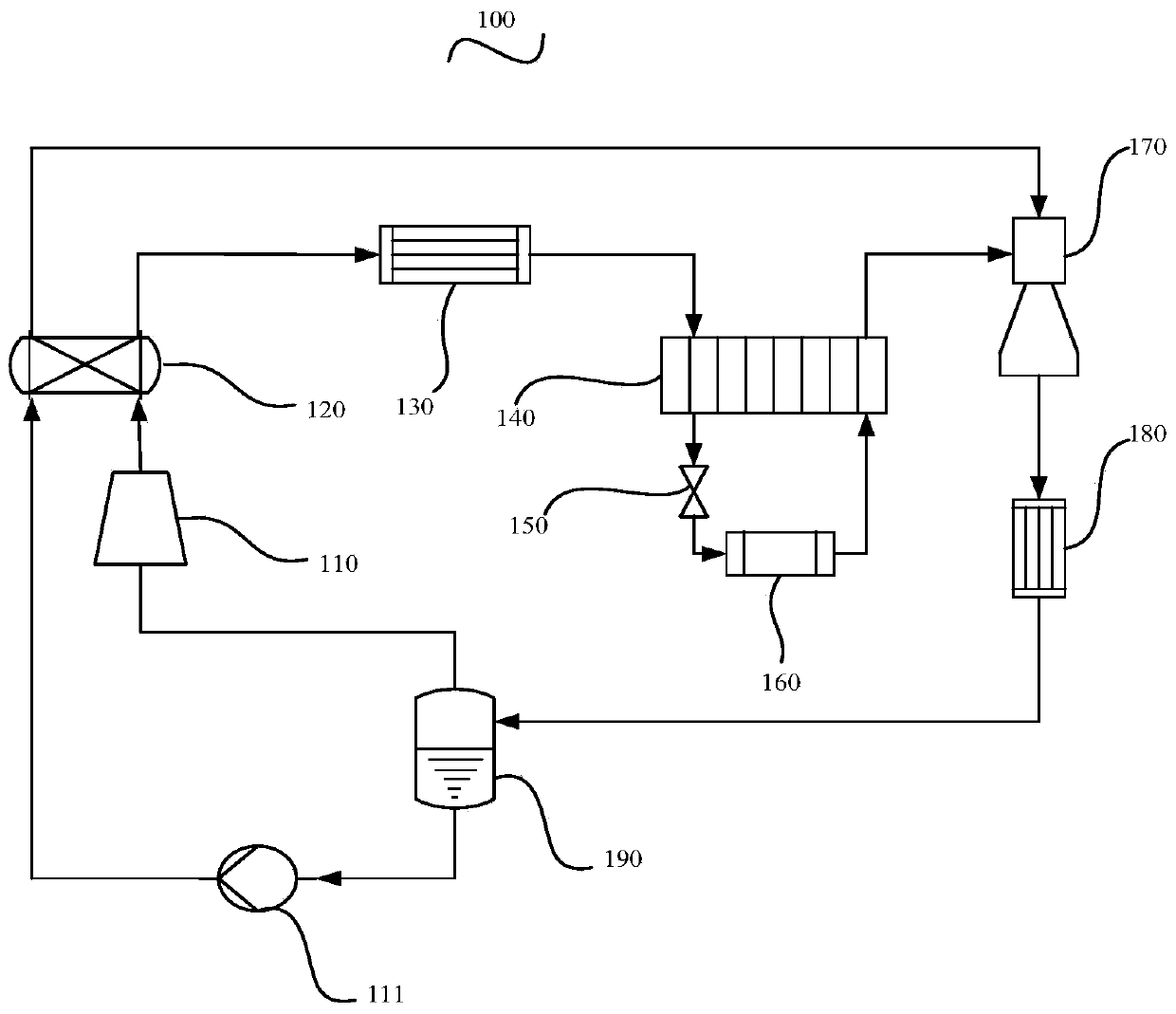

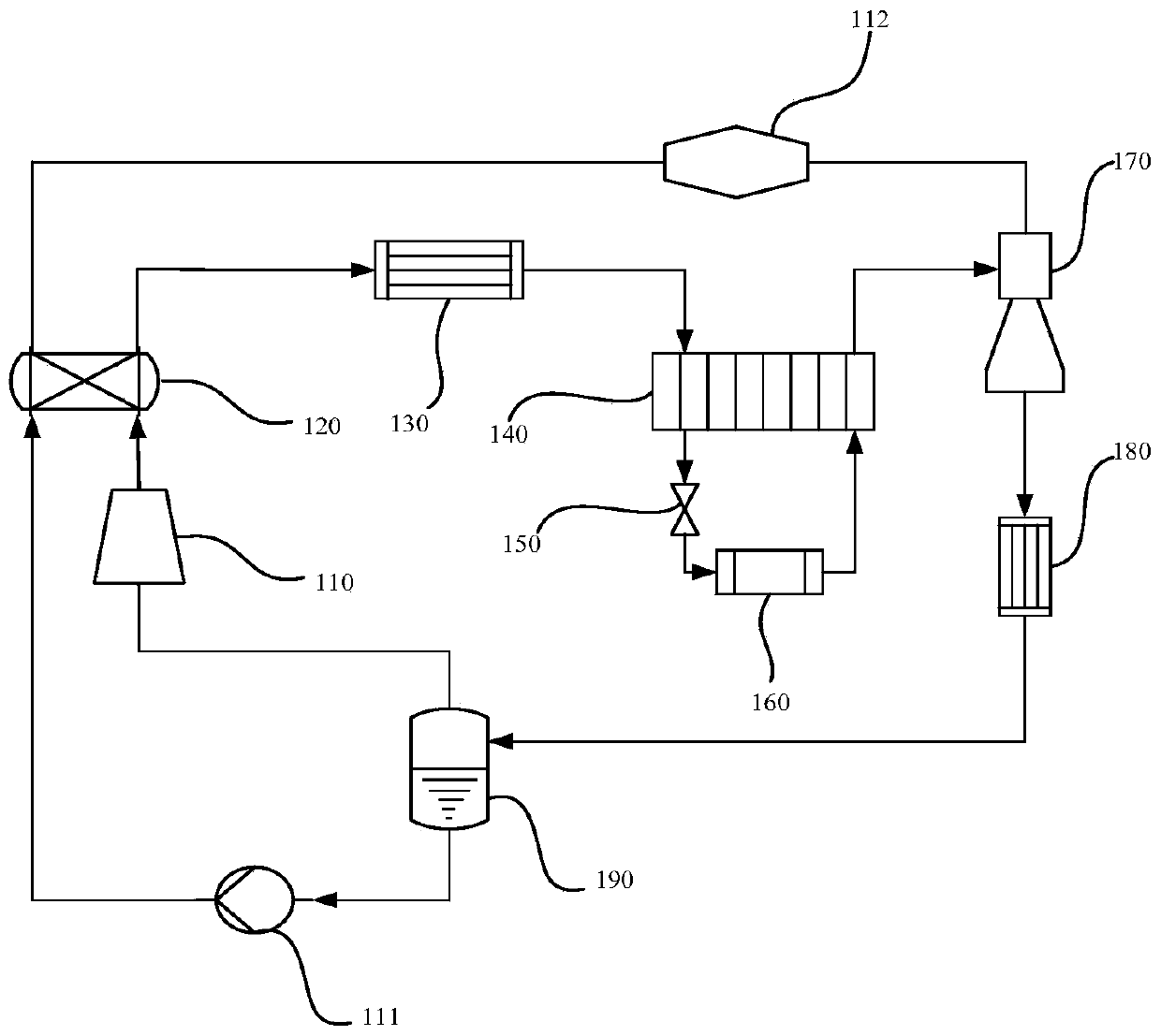

[0058] see Figure 1a , is a schematic structural diagram of a mixed working medium refrigeration cycle system provided in an embodiment of the present invention-a preferred embodiment. The mixed working medium refrigeration cycle system 100 includes: a compressor 110, a generator 120, a first condenser 130, a first Heat exchanger 140 , throttle valve 150 , evaporator 160 , ejector 170 , second condenser 180 , gas-liquid separator 190 and drive pump 111 .

[0059] Wherein, the high pressure outlet of the compressor 110 is connected to the heat exchange inlet of the generator 120, the heat exchange outlet of the generator 120 is connected to the inlet of the first condenser 130, and the outlet of the first condenser 130 is connected to the high pressure inlet of the first heat exchanger 140, The high-pressure outlet of the first heat exchanger 140 is connected to the inlet of the throttle valve 150, the outlet of the throttle valve 150 is connected to the inlet of the evaporator...

Embodiment 2

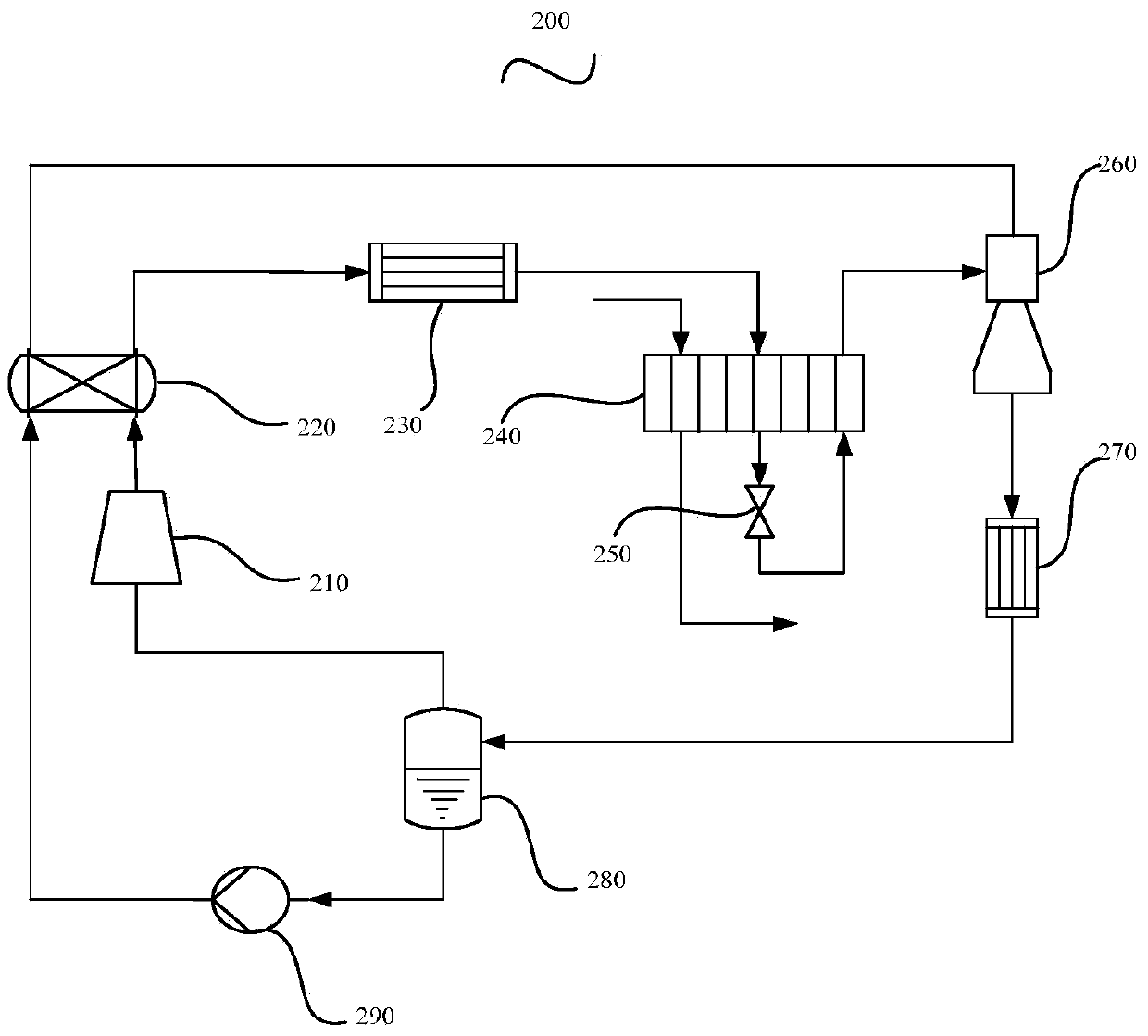

[0064] see Figure 2a , is a schematic structural diagram of a mixed working medium refrigeration cycle system provided in Embodiment 2 of the present invention. The mixed working medium refrigeration cycle system 200 includes a compressor 210, a generator 220, a first condenser 230, a second condenser Heater 240, throttle valve 250, ejector 260, second condenser 270, gas-liquid separator 280 and driving pump 290;

[0065] Wherein, the high pressure outlet of the compressor 210 is connected with the heat exchange inlet of the generator 220, the heat exchange outlet of the generator 220 is connected with the inlet of the first condenser 230, and the outlet of the first condenser 230 is connected with the first high pressure of the second heat exchanger 240. Inlet, the first high-pressure outlet of the second heat exchanger 240 is connected to the inlet of the throttle valve 250, the outlet of the throttle valve 250 is connected to the low-pressure inlet of the second heat excha...

Embodiment 3

[0071] see Figure 3a , is a schematic structural diagram of a mixed working medium refrigeration cycle system provided in Embodiment 3 of the present invention. The mixed working medium refrigeration cycle system 300 includes a compressor 310, a generator 320, a first condenser 330, a third condenser Heater 340, fourth heat exchanger 350, first throttle valve 360, evaporator 370, ejector 380, second condenser 390, gas-liquid separator 311, second throttle valve 312 and drive pump 313 ;

[0072] Wherein, the high pressure outlet of the compressor 310 is connected to the heat exchange inlet of the generator 320, the heat exchange outlet of the generator 320 is connected to the inlet of the first condenser 330, and the outlet of the first condenser 330 is connected to the high pressure inlet of the third heat exchanger 340, The high-pressure outlet of the third heat exchanger 340 is connected to the high-pressure inlet of the fourth heat exchanger 350, the high-pressure outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com