Method for measuring size of caved body obtained through non-sill-pillar sublevel caving mining

A segmented caving and measurement method technology, which is applied in the direction of measuring devices, specific gravity measurement, and analyzing materials, can solve the problems of difficult to determine its volume and failure to measure the volume of caving bodies, so as to fully recover ore resources and reduce the workload of mining , The effect of optimizing the structural parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] specific implementation

[0025] Below in conjunction with accompanying drawing, describe the present invention with embodiment.

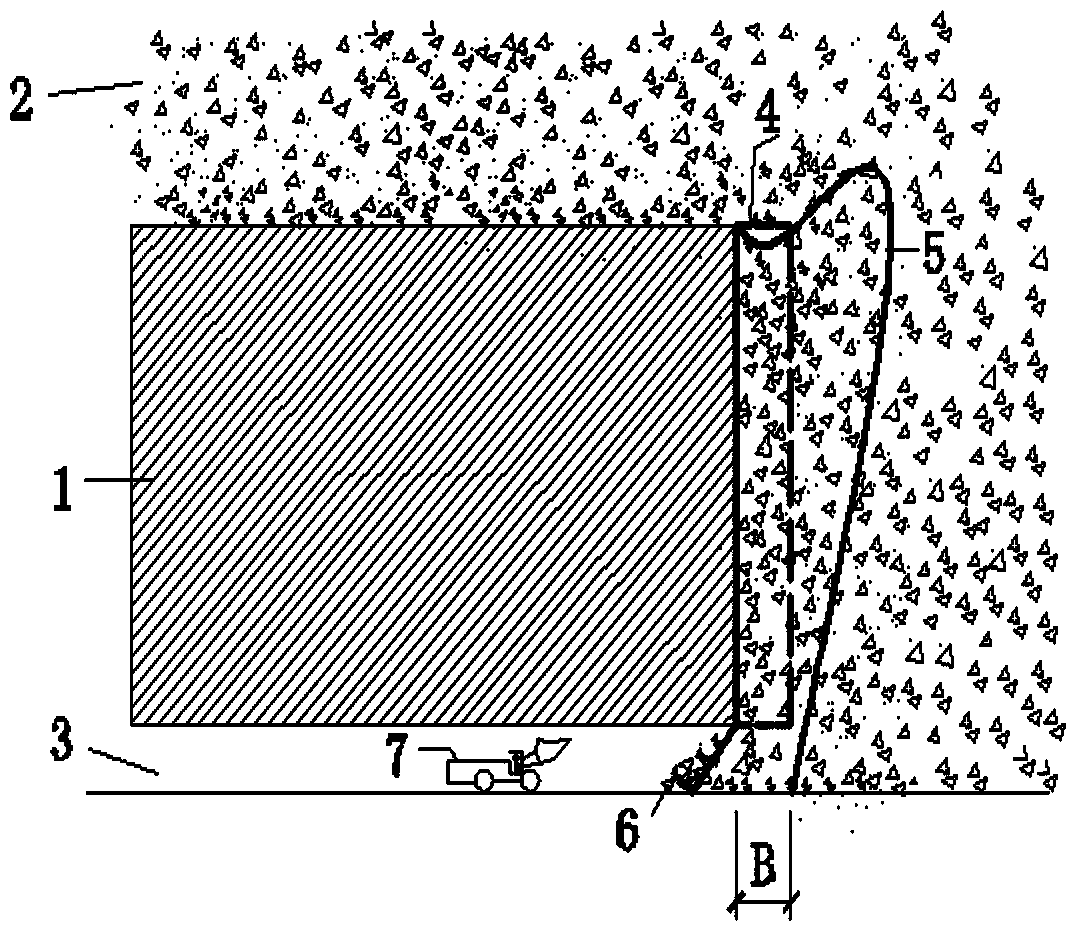

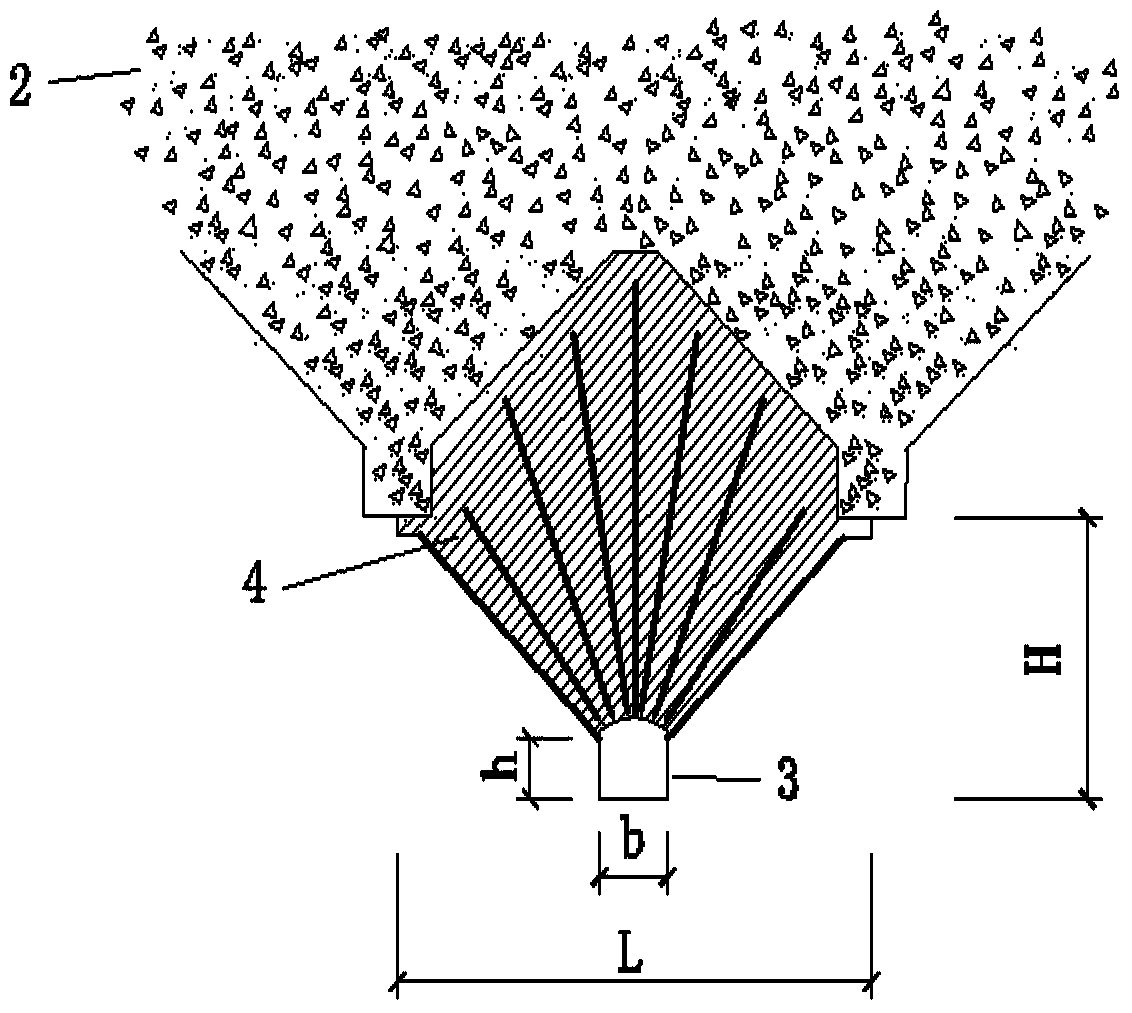

[0026] Such as figure 1 , figure 2 As shown, an iron mine adopts the pillarless segmental caving mining working face, and the working face is distributed with ore body 1, overburden layer 2, mining roadway 3, blasted ore body 4, caving body 5, released ore 6 and electrodynamic Scrapers7. The structural parameters measured at the -33m level are: section height H is 18m, approach distance L is 20m, ore-breaking step distance B is 2.0m, roadway section width b is 5.0m, and height h is 4.4m. Electric scraper 7 bucket capacity is 2m 3 .

[0027] Calculate the volume of the blasted ore body as:

[0028] V 矿体 =B·(H·L-b·h)=2.0×(18×20-5.0×4.4)=676.0m 3

[0029] When going out ore, shovel the ore 6 that three full buckets are discharged with electric shovel machine 7, weigh the gross weight that discharges ore 6 with platform scale to be:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com