Method and device for correcting temperature of thermal mechanical analyzer tensile fixture

A thermomechanical analyzer and temperature correction technology, applied in the direction of measuring devices, analyzing materials, and using stable tension/pressure to test the strength of materials, etc., can solve the problem of no correction method, hindering the sample expansion or shrinkage process, and inaccurate test results and other problems, to achieve the effect of accurate temperature parameters, accurate test results, and avoiding movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

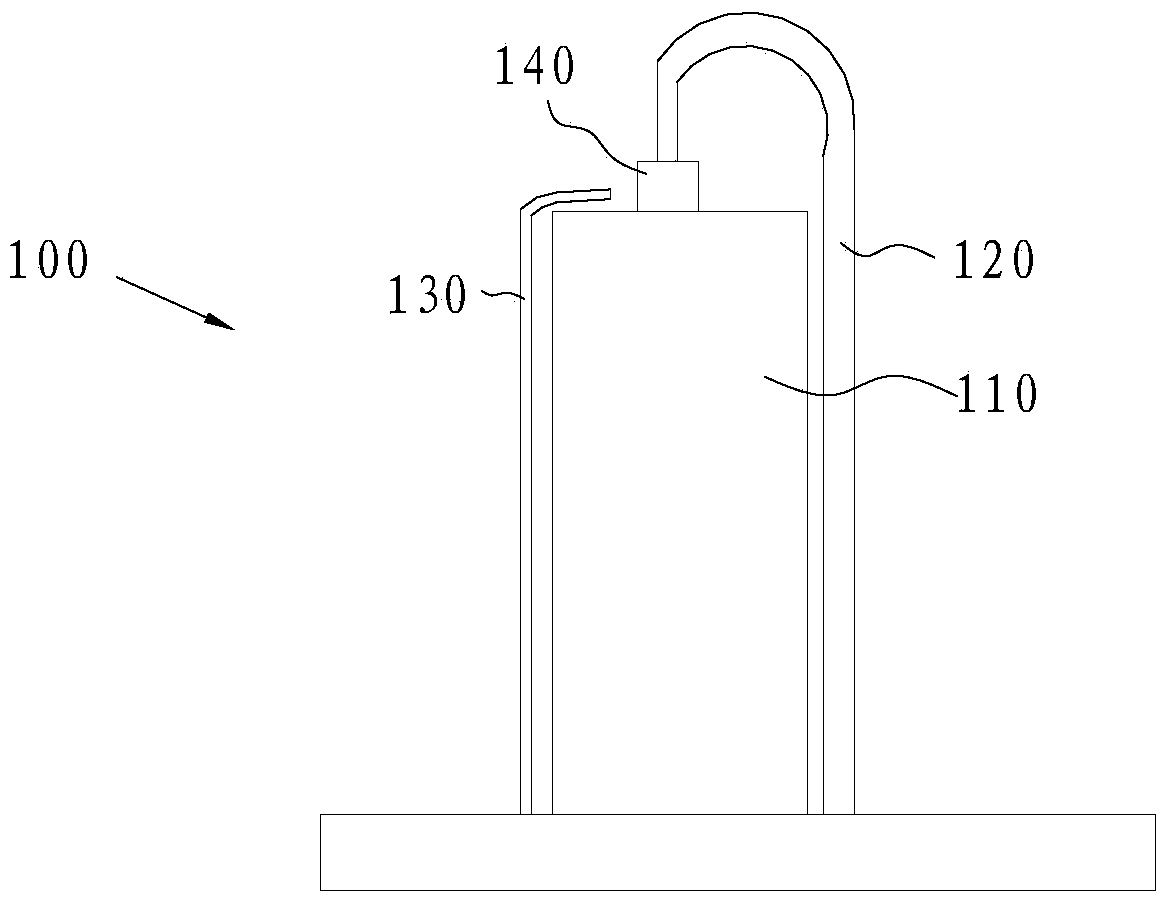

[0071] This embodiment is a temperature correction device designed for the stretching fixture of the TA Q400 type TMA, and the structure of the stretching fixture of the TA Q400 type TMA is referred to figure 2 , which will not be repeated here.

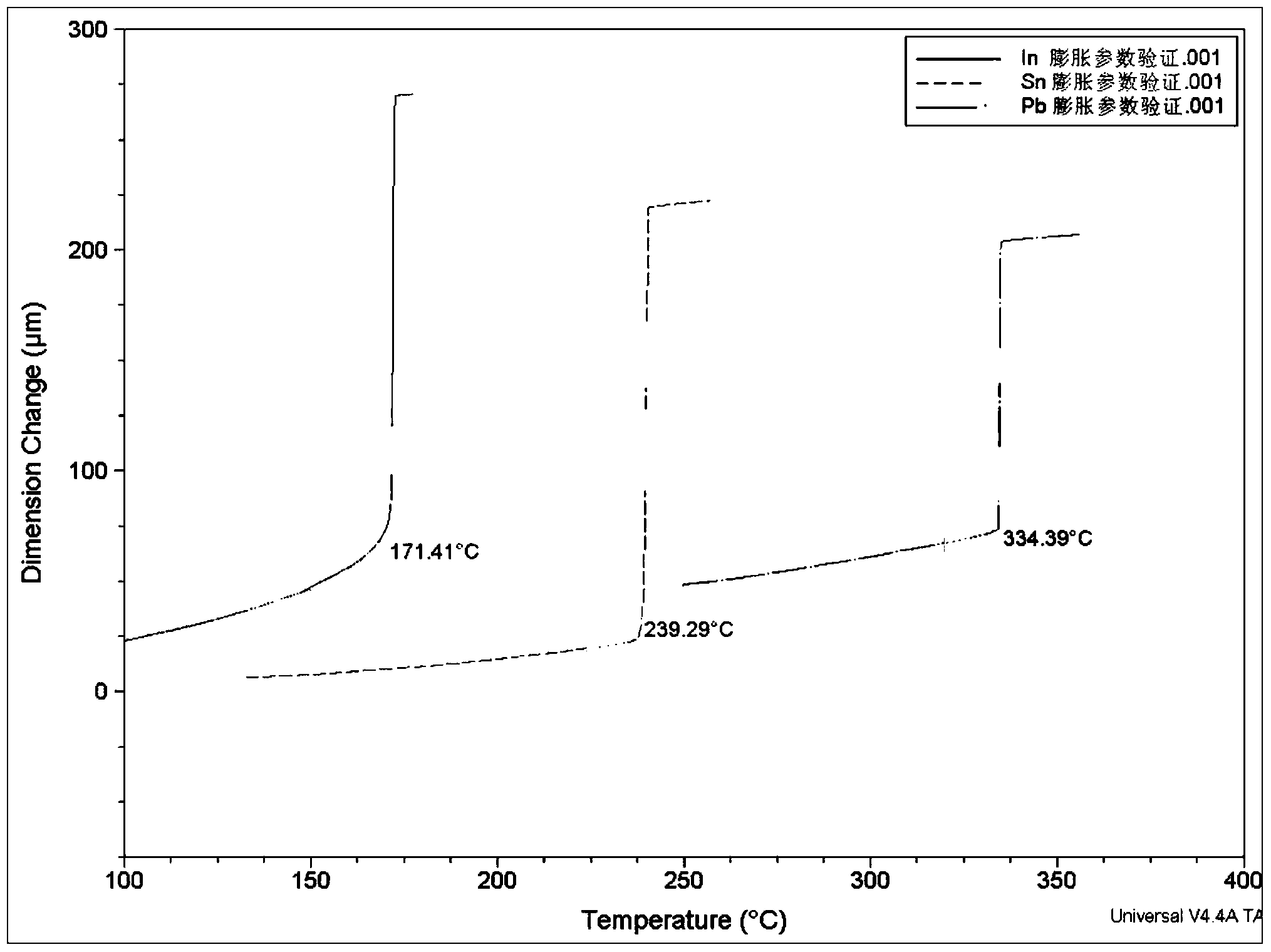

[0072] Such as Figure 4 As shown, the temperature calibration device of the tensile fixture of the thermomechanical analyzer introduced in this embodiment includes a first calibration assembly 10 and a second calibration assembly 20, and the first calibration assembly 10 includes a metal sample 30 for placing a metal sample with a known melting point. The sample holding part 11, the second calibration assembly 20 includes a sample pressing part 21 for pressing the surface of the sample 30 from top to bottom, and the sample pressing part 21 can be connected with the lower clamp of the tensile fixture or with The probe is directly connected, the purpose of which is that when the sample is heated to a molten state, the probe can sens...

Embodiment 2

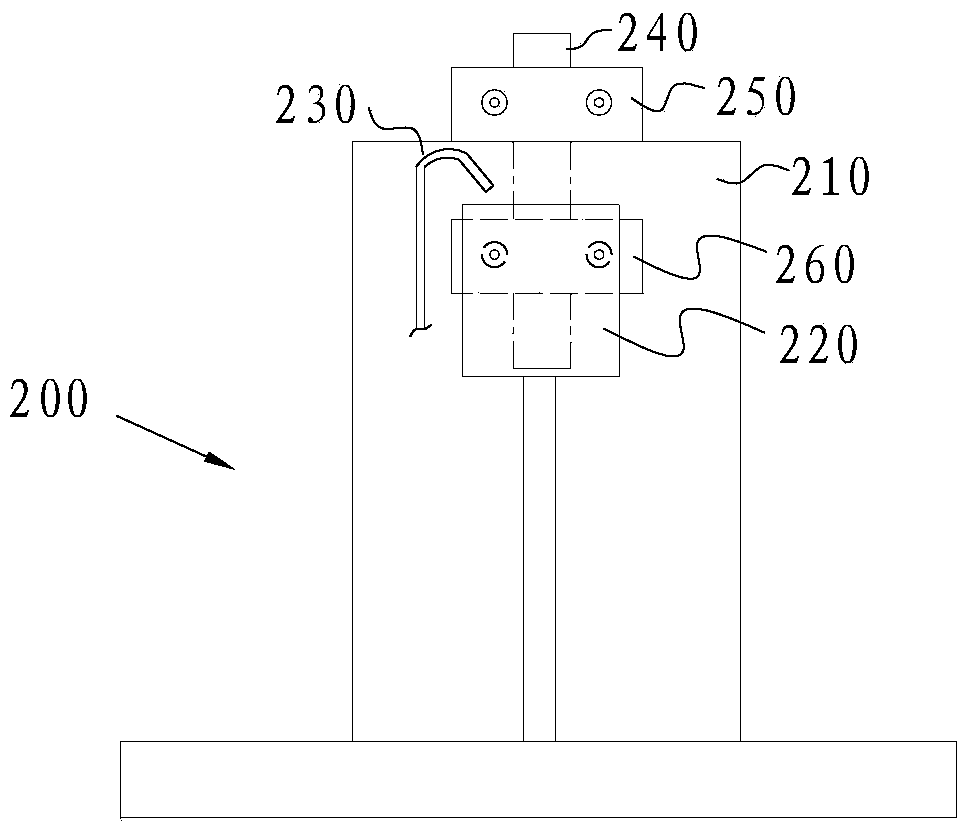

[0099] This embodiment is a temperature correction device designed for the stretching fixture of SDTA840 type TMA, and the structure of the stretching fixture of SDTA840 type TMA refers to Figure 9 , the tensile fixture 300 includes a sample holder 310, a probe 320, and a thermocouple 330. The sample holder 310 and the thermocouple 330 are of an integrated structure. An upper fixture 340 and a lower fixture 350 are arranged inside the sample holder 310. Both the upper and lower fixtures are In the shape of a hook, the sample is clamped between the upper and lower clamps.

[0100] Figure 10 Shown is a temperature calibration device suitable for the above-mentioned tensile fixture, which includes a first calibration assembly 40 and a second calibration assembly 50, and the first calibration assembly 40 includes a sample holder for placing a metal sample 60 with a known melting point 41. The second calibration assembly 50 includes a sample pressing part 51 for pressing the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com