Transmitting device for diaphragm gas meter

A membrane gas meter and driving device technology, which is applied in the direction of measuring devices, instruments, liquid/fluid solid measurement, etc., can solve problems such as disputes between gas companies and users, less counting, errors in counting and actual consumption, etc., and achieve stable and reliable signals output, simple structure effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

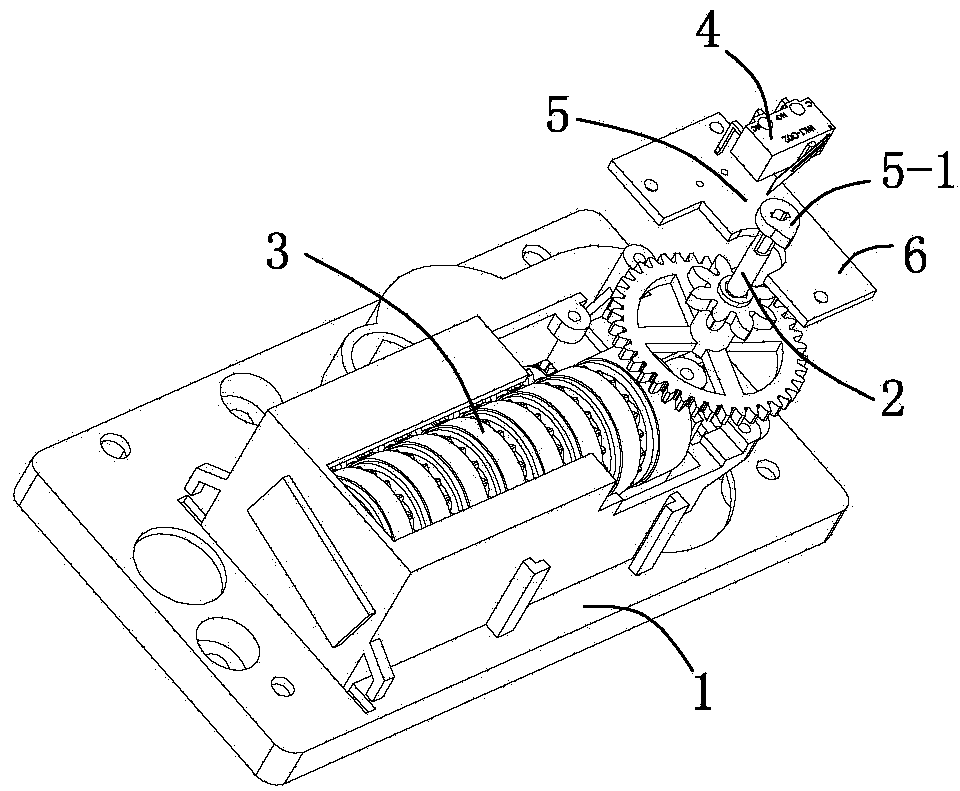

[0024] This embodiment is a preferred solution to the structure of the above-mentioned membrane gas meter signaling device: in the structure, as figure 1 As shown: the driving device is a cam 5-1, the cam is sleeved on the rotating shaft to rotate with the rotating shaft, and the protrusion of the cam pushes the contact of the micro switch to send an on-off counting signal.

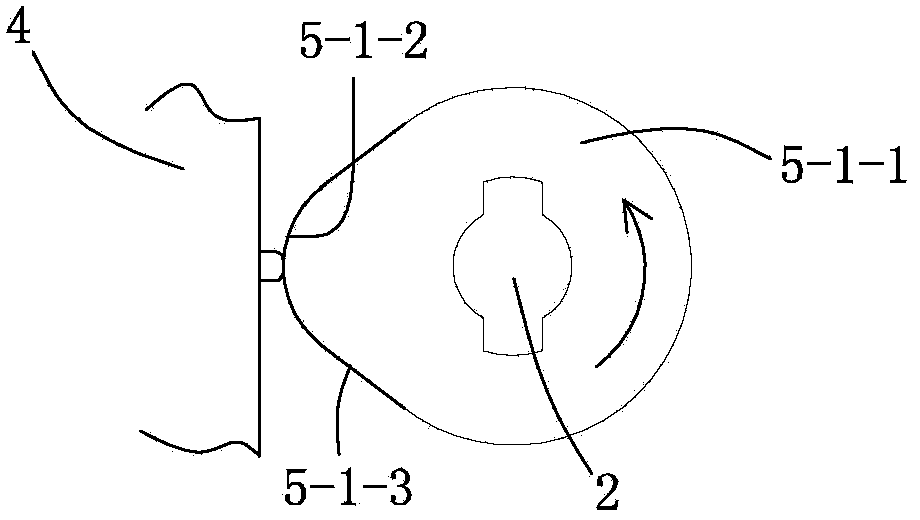

[0025] In the embodiment, such as figure 2 As shown, the protrusion of the cam is an arc-shaped protrusion 4-1-2 on the edge of the cam disc 5-1-1, and the arc-shaped protrusion is smoothly connected to the edge of the disc 5-1-3. The height is 1 / 3 to 1 / 2 of the radius of the disc.

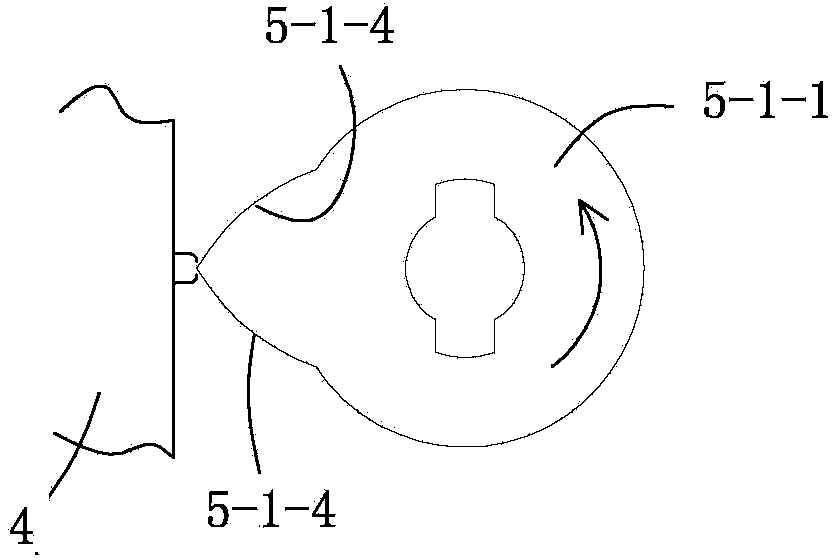

[0026] In the embodiment, the protrusion can also be another way, such as image 3 As shown: the protrusion is a protrusion formed by butting two arcs 5-1-4 symmetrical to the center of the cam disc, and the height of the protrusion is 1 / 3 to 1 / 2 of the radius of the cam disc.

[0027] In this embodiment, two arcs that are symmetri...

Embodiment 2

[0029] This embodiment is another preferred solution to the structure of the above-mentioned membrane gas meter signaling device: in the structure, as image 3 As shown, the driving device is a shaft sleeve 5-2. The shaft sleeve is sleeved on the shaft and is positioned radially without rotating with the shaft. The rotation of the shaft drives the shaft sleeve to move up and down to push the micro switch contacts to issue a count signal of on-off.

[0030] There are several ways to drive the shaft sleeve to move up and down:

[0031] One of the ways: such as Figure 4 Shown: the inner wall of the sleeve hole of the shaft sleeve is provided with a closed curved groove 5-2-1, and the rotating shaft is provided with a protrusion 2-1 matching the groove. When the rotating shaft rotates, the rotating shaft protrudes in the groove The rotary sliding drives the shaft sleeve to move up and down. The closed curve is a closed curve from rising to falling, and the rising angle of the curve is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com