Active damage monitoring device and method for hydraulic concrete structure

A technology for hydraulic concrete and structural damage, which is applied in processing detection response signals, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., and can solve problems such as the difficulty of damage sensitive frequencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

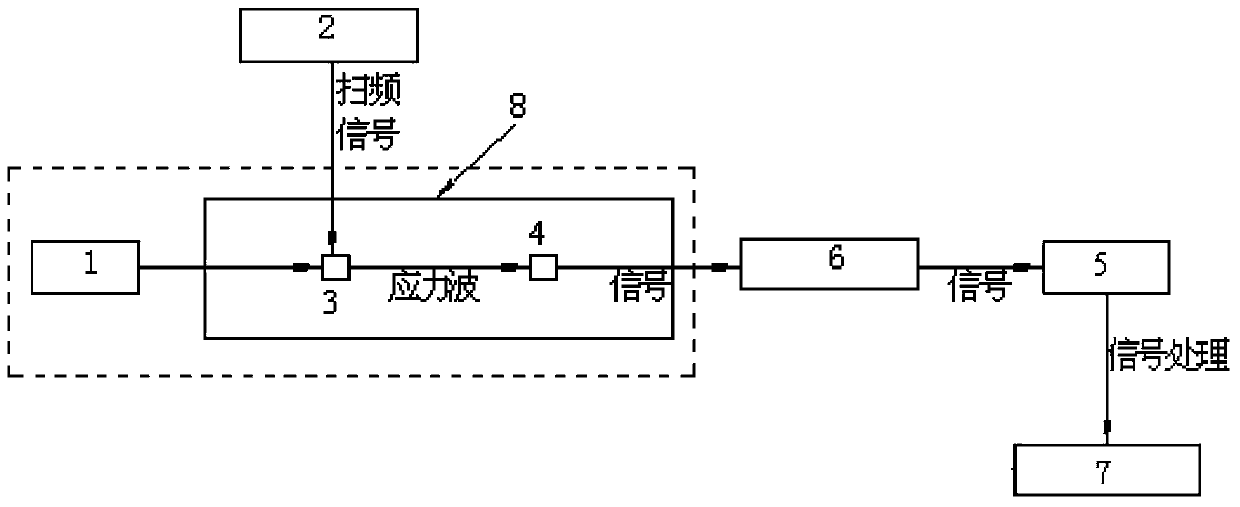

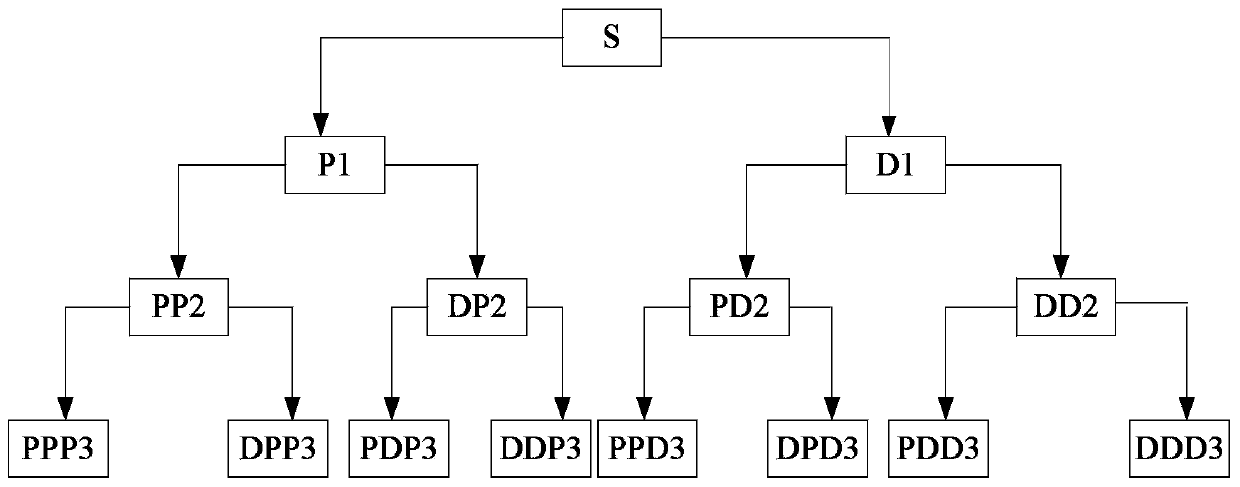

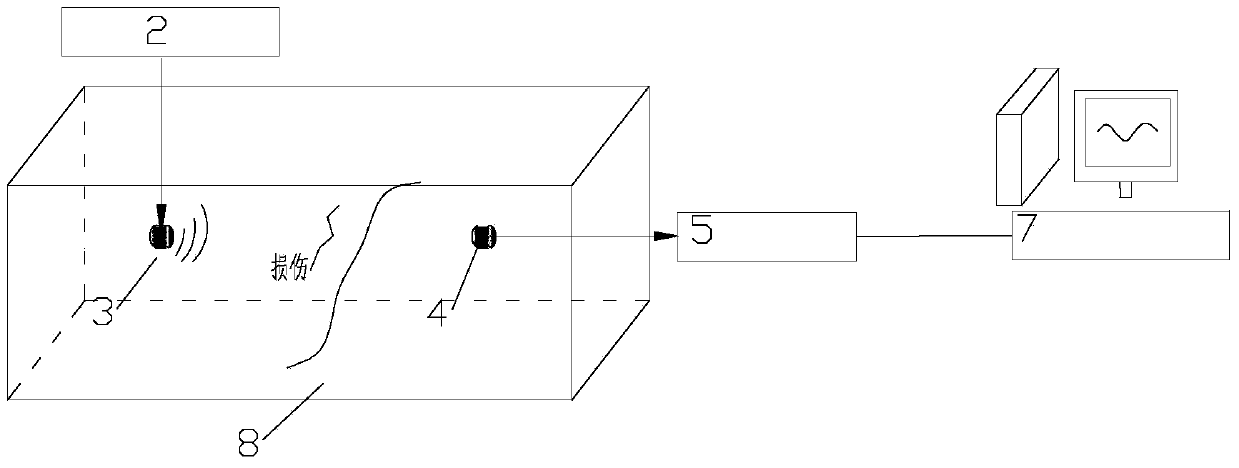

[0034] Embodiment 1: The active monitoring device for hydraulic concrete structure damage of the device of the present invention includes a vibration table 1, a waveform generator 2, a driver 3, a sensor 4, a digital filter 6, a digital collector 5, a wavelet packet analysis system 7 and a measured A hydraulic concrete structure 8; the measured hydraulic concrete structure 8 is set on the vibrating table 1, and after the waveform generator 2 sends a sweep signal to the driver 3, the driver 3 is excited to generate a stress wave, The stress wave propagates in the measured hydraulic concrete structure 8 and is received by the sensor 4, and the stress wave signal passes through the digital filter 6, the digital collector 5 and the wavelet packet analysis system 7 in turn; the driver 3 and the sensor 4 are pressure Electric ceramic smart module, the driver 3 and the sensor 4 are respectively embedded or pasted on the two ends of the hydraulic concrete structure 8 to be tested; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com