Colored optical fiber and manufacturing method thereof

A technology for coloring optical fibers and coloring layers, applied in the field of optical communication, can solve the problems of easy sticking, the coating layer, the coloring layer and the conjoined layer cannot be peeled off as a whole, and the eye mold is easy to block, and the effect of easy control is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

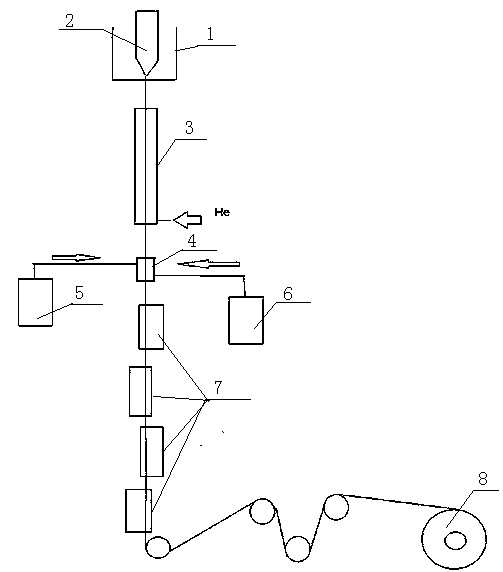

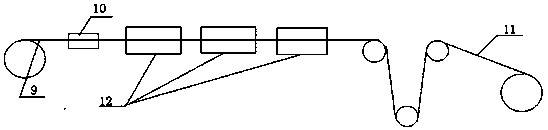

[0020] to combine figure 1 and 2 The present invention is described.

[0021] The preform 2 was heated in the heating furnace 1, and then passed through the cooling barrel 3 to obtain a bare optical fiber. The structure of the bare fiber is the core and the cladding from the inside to the outside. The bare optical fiber passes through the eye mold 4 at a speed of 1500m / min-1800m / min, and the first coating layer and the second coating layer are successively coated in the eye mold. After the bare optical fiber is coated with the first coating layer and the second coating layer, the coating layer is cured by using a UV lamp 7 to obtain a natural-color optical fiber. When the coating layer is cured, the optical fiber passes through four lamps in turn with an illumination of 11 mw / cm 2 UV lamp (D type), curing time 0.17s, after which the optical fiber is wound onto the optical fiber reel through the tension wheel and dancer wheel.

[0022] Coloring treatment: the natural co...

Embodiment 2

[0025] The preform is heated in a heating furnace and then passed through a cooling barrel to obtain a bare optical fiber. The structure of the bare fiber is the core and the cladding from the inside to the outside. The bare optical fiber passes through the eye mold at a speed of 1500m / min to 1800m / min, and the first coating layer and the second coating layer are successively coated in the eye mold. After the bare optical fiber is coated with the first coating layer and the second coating layer, the coating layer is cured with a UV lamp to obtain a natural color optical fiber. When the coating layer is cured, the optical fiber passes through four lamps in turn with an illumination of 12.5 mw / cm 2 UV lamp (D type), curing time 0.16s, after which the optical fiber is wound onto the optical fiber reel through the tension wheel and dancer wheel.

[0026] Coloring treatment: The natural color optical fiber passes through the coloring mold at a speed of 1500m / min~1800m / min, coated...

Embodiment 3

[0028] The preform is heated in a heating furnace and then passed through a cooling barrel to obtain a bare optical fiber. The structure of the bare fiber is the core and the cladding from the inside to the outside. The bare optical fiber passes through the eye mold at a speed of 1500m / min to 1800m / min, and the first coating layer and the second coating layer are successively coated in the eye mold. After the bare optical fiber is coated with the first coating layer and the second coating layer, the coating layer is cured with a UV lamp to obtain a natural color optical fiber. When the coating layer is cured, the optical fiber passes through four lamps in turn with an illumination of 11.5 mw / cm 2 UV lamp (Type D), curing time 0.165s, after which the optical fiber is wound onto the optical fiber reel through the tension wheel and dancer wheel.

[0029] Coloring treatment: The natural color optical fiber passes through the coloring mold at a speed of 1500m / min~1800m / min, coate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com