Split type integrated pressurized water reactor hanging under the hanging basket

A split-type, pressurized water reactor technology, applied in the direction of moderator/core structure, reactor, greenhouse gas reduction, etc., can solve the problems of inconvenient installation, difficult installation and disassembly, complicated installation structure, etc. Disassembly, easy in-service inspection, reduction in axial dimension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

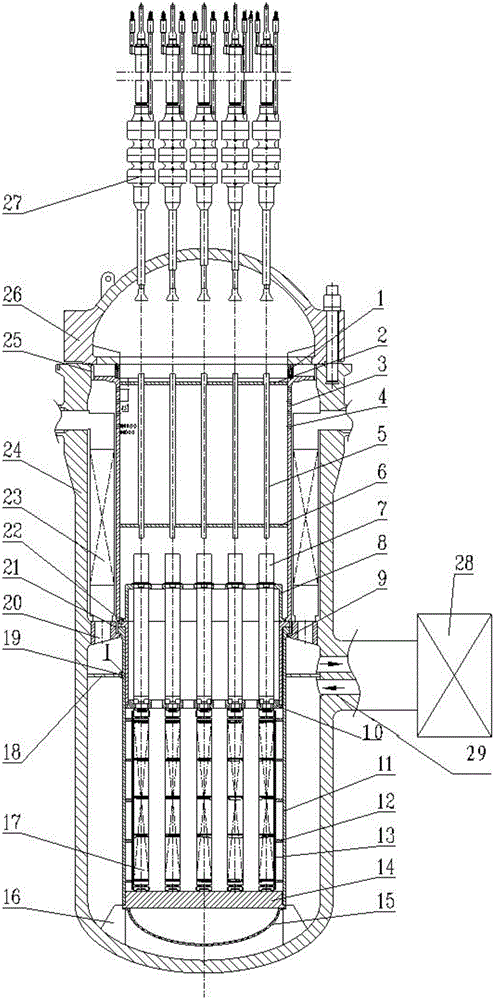

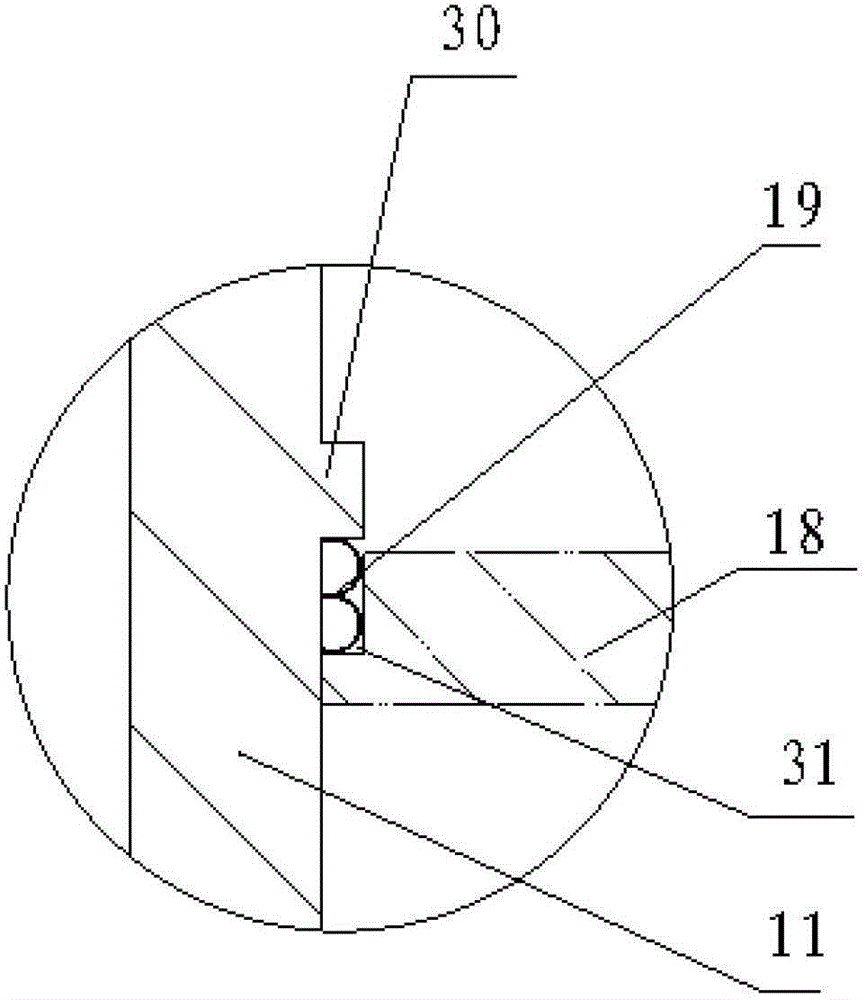

[0026] Such as figure 1 As shown, the radial limit block 16 is welded at the bottom of the pressure vessel cylinder 24, and the inner wall of the pressure vessel cylinder 24 is processed with a ring-shaped hanging basket supporting step 20, and the hanging basket assembly is located under the pressure of the hanging basket supporting step 20. At the bottom of the container cylinder 24, the above-mentioned radial limit block 16 can limit the radial movement of the hanging basket assembly. Weld the flow shunt cover 15 under the hanging basket assembly. A fuel assembly 17 is installed at the bottom of the hanging basket assembly, a pressing assembly is fixedly installed on the hanging basket assembly, and a guide assembly 7 is fixedly installed on the pressing assembly. Above the compression assembly is a compression cylinder assembly, and a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com