Dual-image-sensor packaging module and formation method therefor

An image sensor and sensor technology, which is used in electric solid-state devices, semiconductor devices, radiation control devices, etc., can solve the problems of low integration of dual cameras and accurate images.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

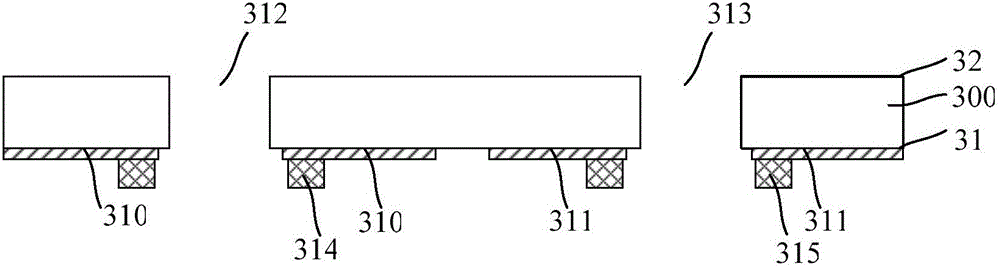

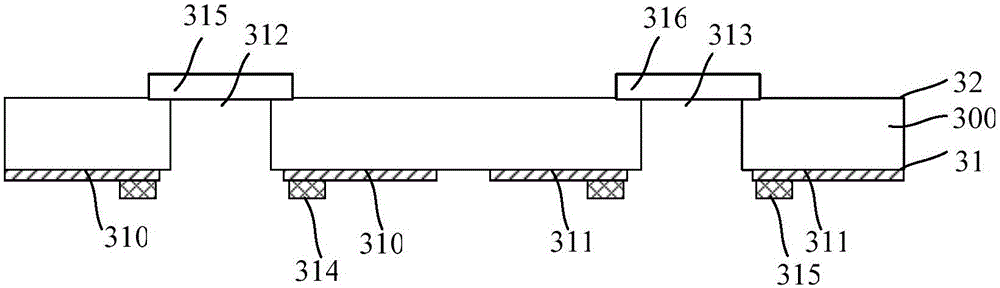

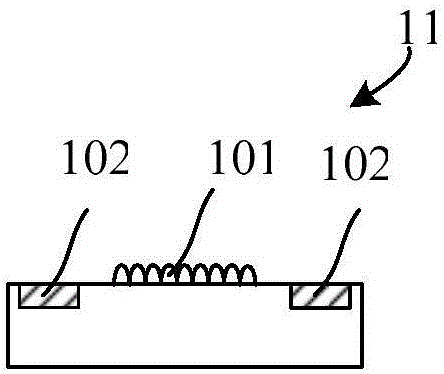

[0066] As mentioned in the background, the existing dual cameras have a low integration level, and the accuracy of acquiring images is limited by the images.

[0067] Research has found that the existing dual cameras are usually implemented by connecting two image sensor modules to the PCB boards of corresponding devices (such as mobile phones), which makes the dual cameras occupy a larger volume and makes the integration of the dual cameras lower. , and when connecting two independent image sensor modules to the PCB board of the corresponding device (such as a mobile phone), the connection process used is usually a welding process, which easily makes the heights of the two image sensor modules inconsistent, thus making the two The heights of the corresponding two image sensors in the image sensor module may be inconsistent, which affects the accuracy of the two image sensors when acquiring images.

[0068] To this end, an embodiment of the present invention provides a dual im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com