Sock design and weaving integrated system and method

An integrated system and socks technology, applied in the field of three-dimensional digital design and manufacturing, can solve the problems of low efficiency, no unified process standard in the production process of socks, and two-dimensional digitalization relying on labor, etc., to reduce labor intensity, shorten production cycle, shorten Effects of the weaving cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

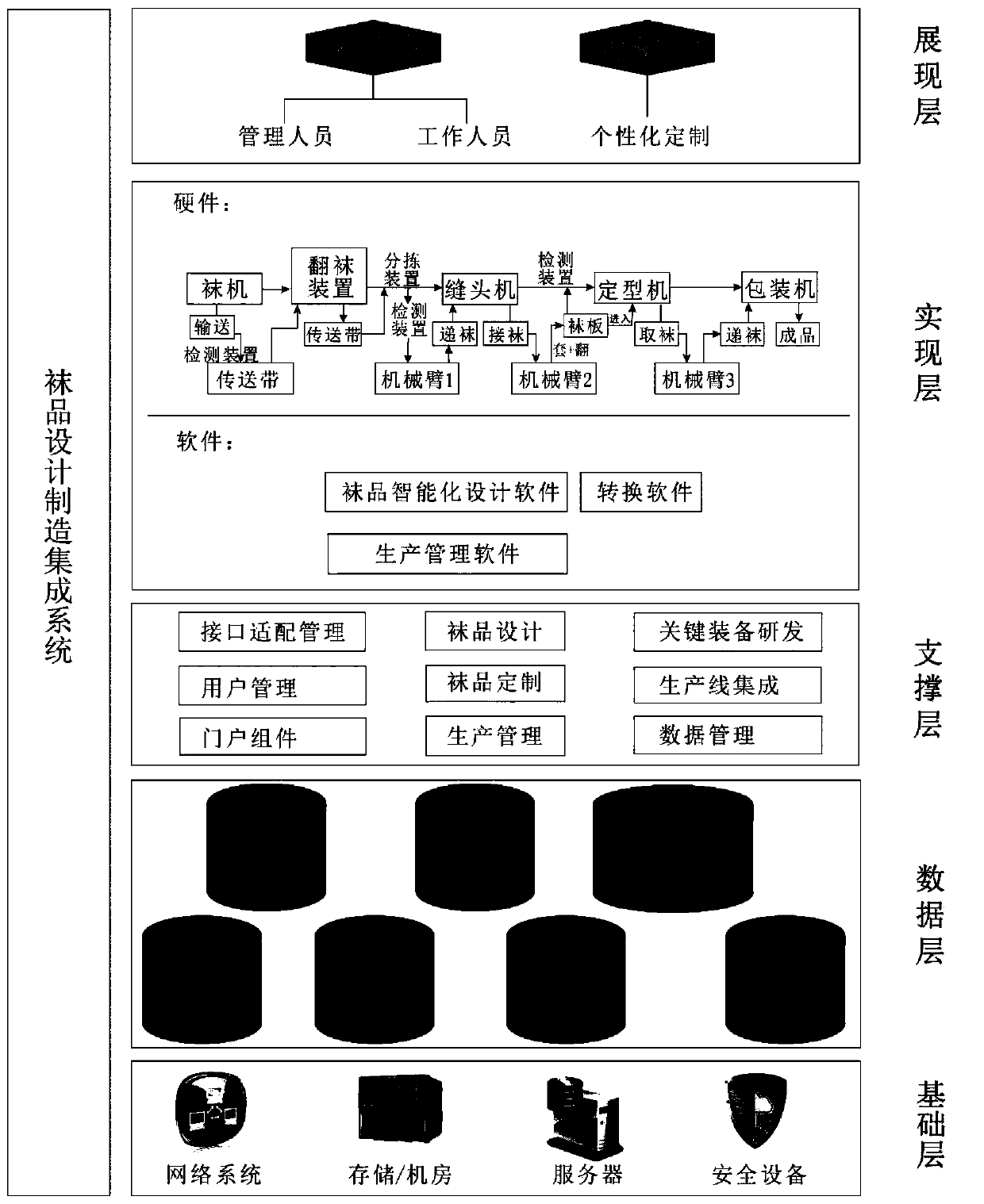

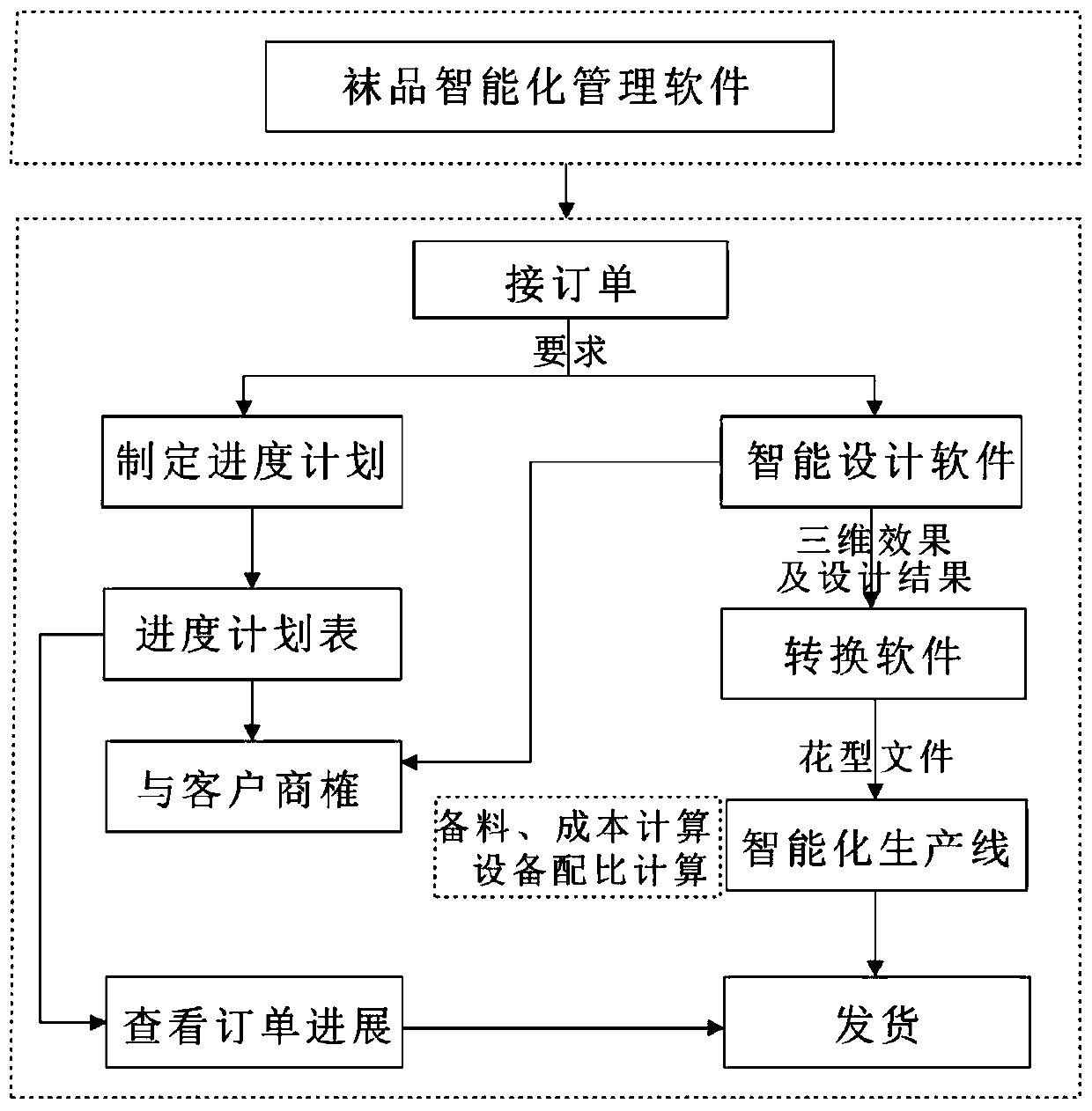

[0037] A hosiery design and weaving integrated system, such as figure 1 As shown, it includes five modules including the basic layer, data layer, support layer, implementation layer and presentation layer, covering the infrastructure, background data, implementation methods and presentation methods required in the system, and integrating software and hardware;

[0038] The base layer includes network equipment, storage equipment, security equipment and servers;

[0039] The data layer includes a product display library; a product material library; a human foot size information library; an order library; an equipment library;

[0040] The support layer includes interface adaptation management, user management, portal components, socks design, socks customization, production management, key equipment research and development, production line int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com