Automatic candy-box box-covering machine

A candy box, automatic technology, used in flange-type bottle caps, bottle/container caps, and container closures with lids, etc., can solve the problems of incompatibility with mass production, low efficiency of semi-automatic production mode, and rising labor costs. , to achieve good economic benefits, reduce labor costs, and improve processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

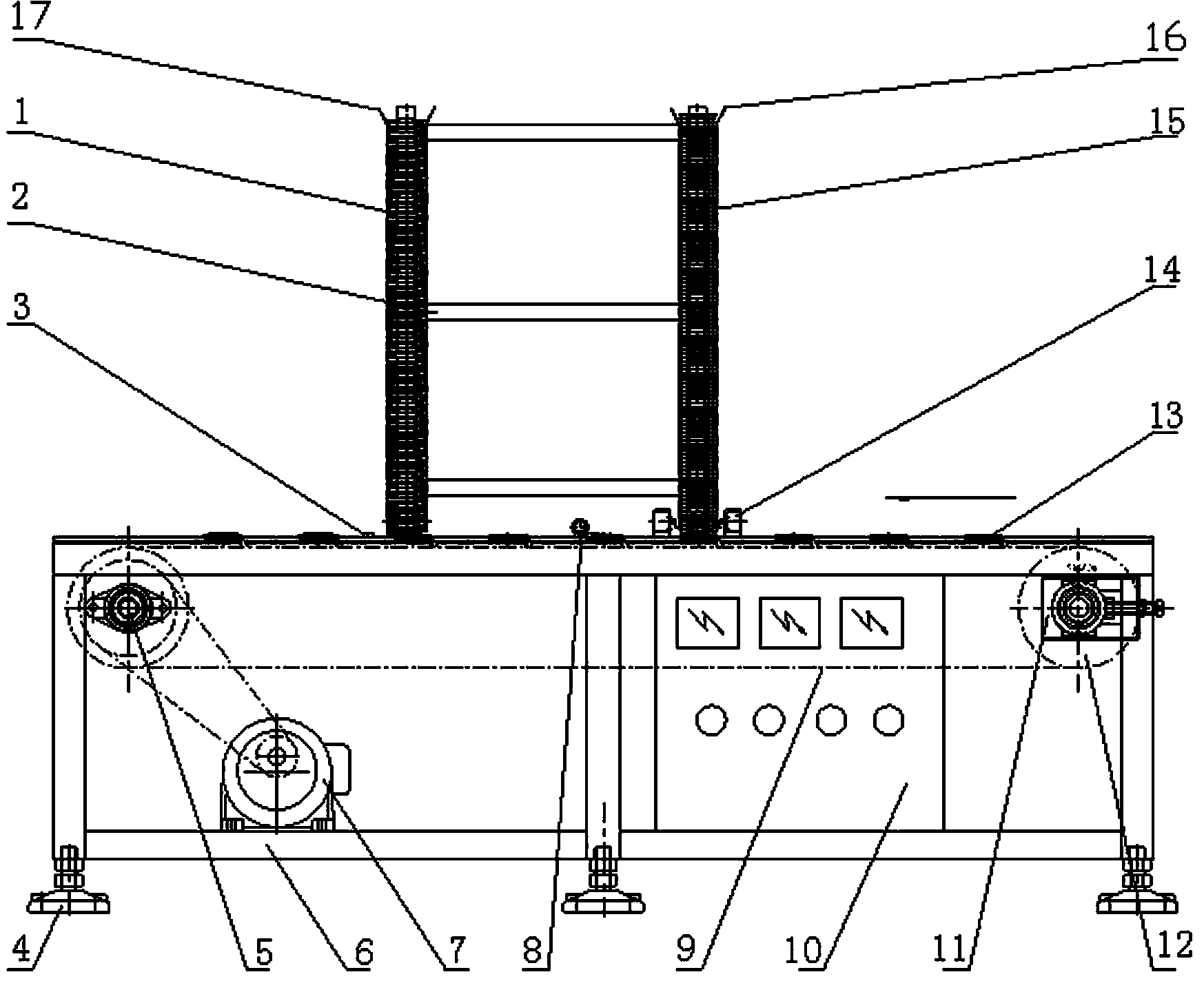

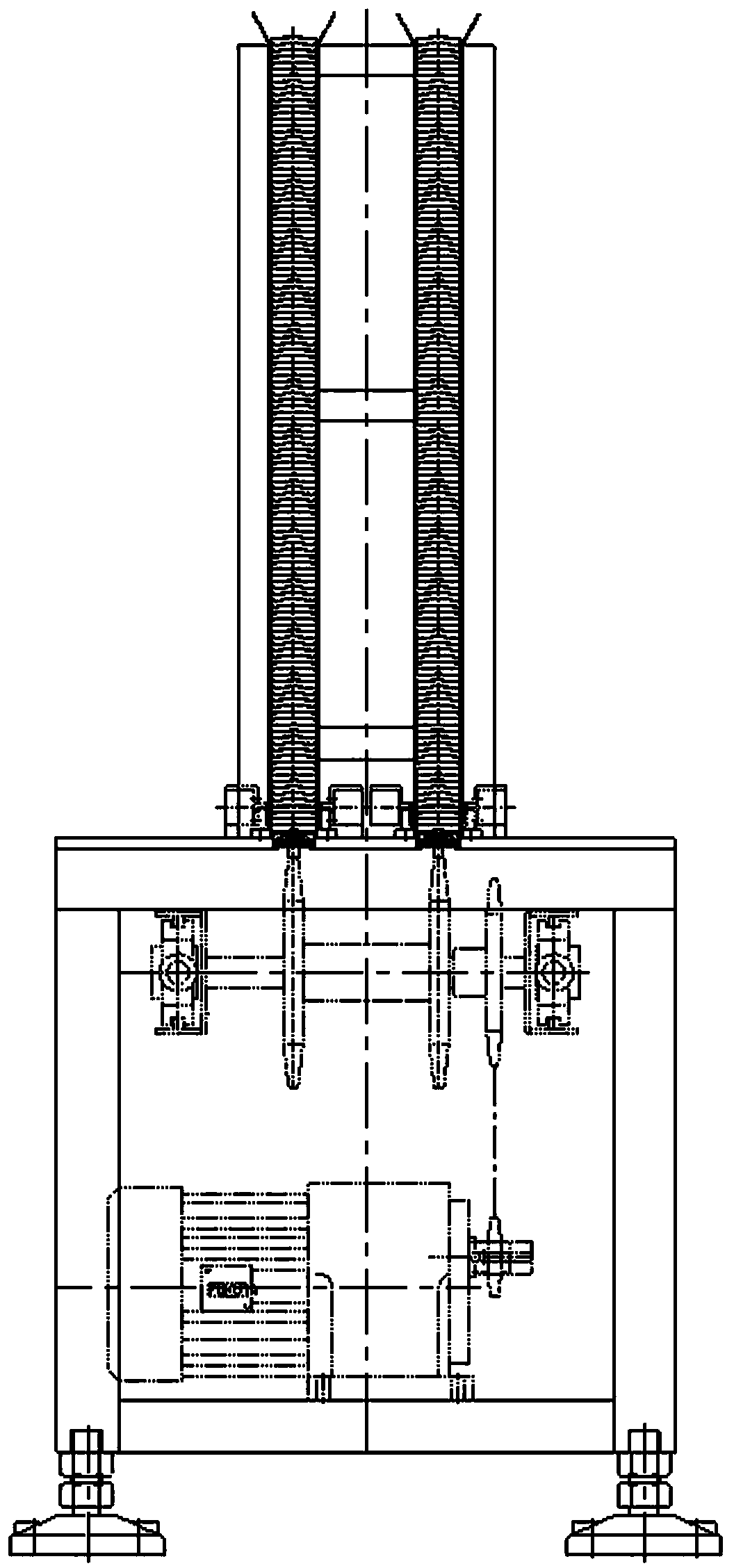

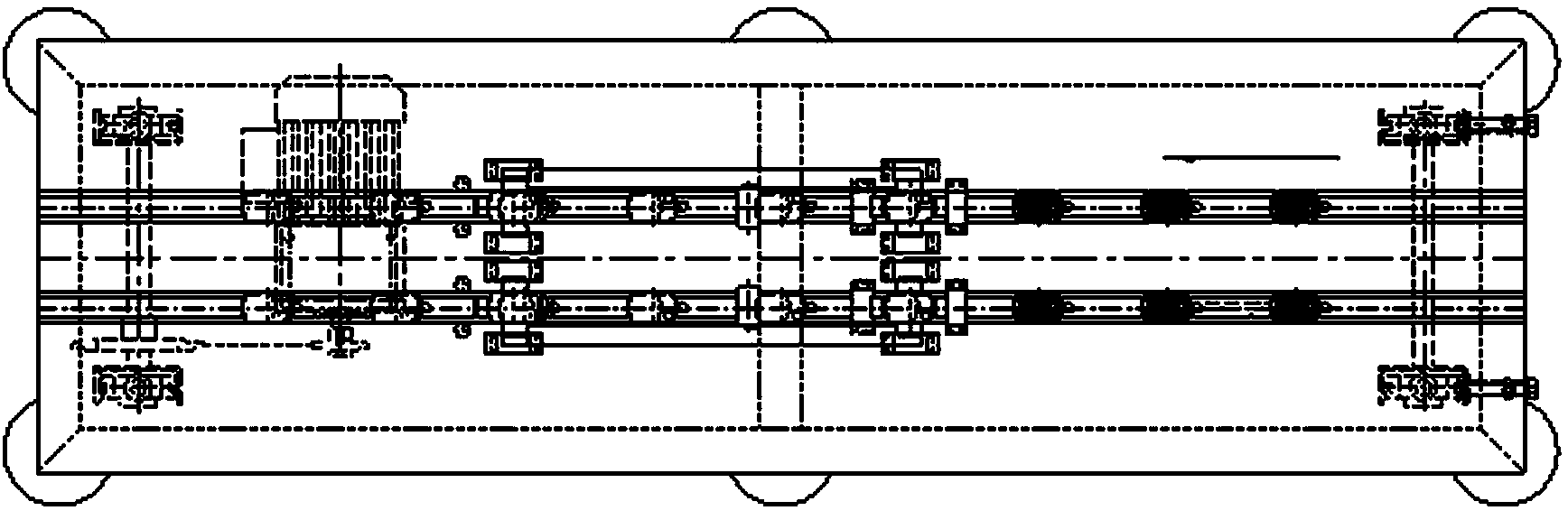

[0020] Such as Figure 1 to Figure 3 As shown, the candy box automatic lidding machine includes a frame and a housing 6. The frame and the housing 6 are provided with two fixed bearing seats 5 at the left end and two adjustable bearing seats 11 with adjustable positions at the right end. , Both the bearing housing 5 and the adjustable bearing housing 11 are provided with a drive shaft with two conveying sprockets 12, and a total of two parallel baffle chains 9 are connected between the conveying sprockets 12 , Forming 2 sets of sprocket pairs, the drive shaft arranged on the bearing seat 5 and the reduction motor 7 are connected by a chain pair, the frame and the housing 6 are fixedly provided with a material cover storage tank and a bracket 2, the material The cover storage tank and the bracket 2 from left to right include two metal cover storage tanks 17 for accommodating the metal cover 1 and two plastic cover storage tanks 16 for accommodating the plastic cover 15. The meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com