A kind of wave-absorbing radiation-proof plastic and its preparation method

A technology of anti-radiation and plastics, applied in the field of engineering plastics and its preparation, can solve problems such as brittleness, lack of anti-radiation effect of absorbing waves, defects, etc., and achieve good effects, good elimination of electromagnetic waves, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

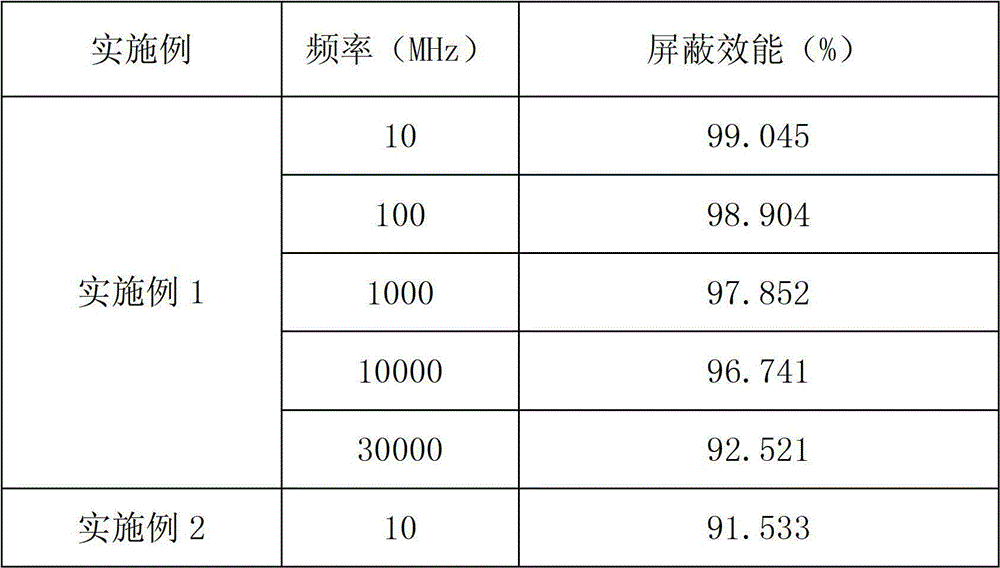

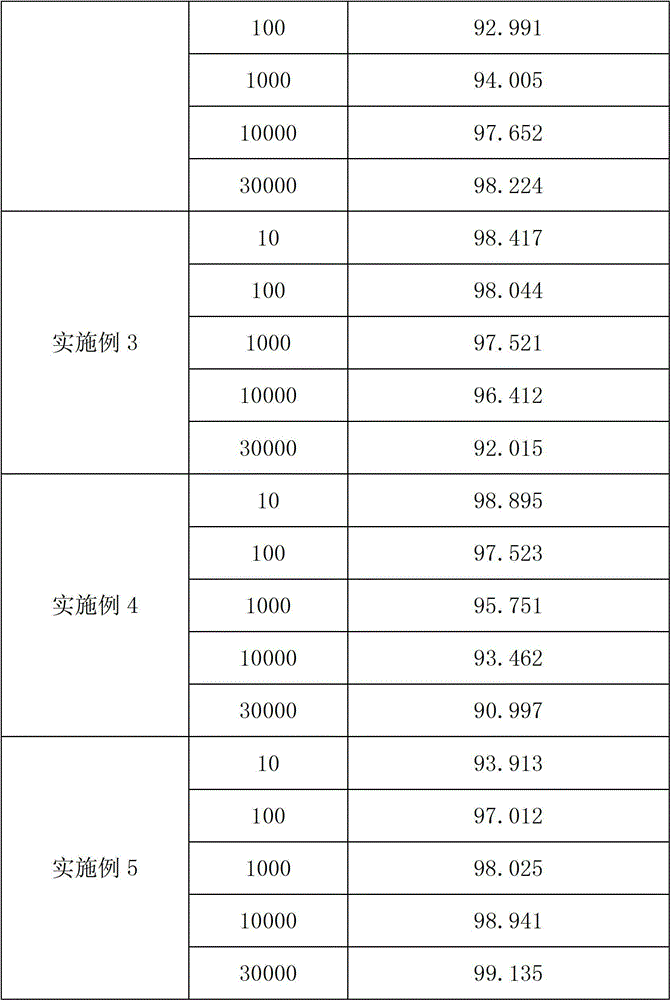

Examples

Embodiment 1

[0033] 1. Prepare raw materials according to the following weight ratio (×100g)

[0034] Polypropylene (PP) 60

[0035] Wave-absorbing and radiation-proof accessories 40

[0036] Auxiliary 3.6

[0037] Among them, the wave-absorbing and anti-radiation auxiliary material is composed of acetylene carbon black and carbonyl iron powder. The weight ratio of acetylene carbon black and carbonyl iron powder is 80:20, that is, the weight of acetylene carbon black is 3200g, and the weight of carbonyl iron powder is 800g. Its average particle size is 2-3μm, and the auxiliary agent is dispersant N, N' ethylene bis stearamide.

[0038]2. Add polypropylene (PP) raw materials, acetylene carbon black, carbonyl iron powder and additives into a high-speed mixer for mixing, and stir to make a plastic mixture. The mixing speed is 700rpm , the mixing time is 25min, and the mixing temperature is 170°C.

[0039] 3. Extrude the above-mentioned prepared plastic mixture directly with a conical twin...

Embodiment 2

[0042] 1. Prepare raw materials according to the following weight ratio (×100g)

[0043] Acrylonitrile-butadiene-styrene copolymer (ABS) 70

[0044] Wave-absorbing and radiation-proof accessories 30

[0045] Additive 3.5

[0046] Among them, the wave-absorbing and anti-radiation auxiliary material is composed of acetylene carbon black and carbonyl iron powder. The weight ratio of acetylene carbon black and carbonyl iron powder is 50:50, that is, the weight of acetylene carbon black is 1500g, and the weight of carbonyl iron powder is 1500g. Its average particle size is 2-3μm. The auxiliary agent is N, N' ethylene bis stearamide as a dispersant; PE wax as a lubricant, including 250g of N, N' ethylene bis stearamide and 100g of PE wax.

[0047] 2. Add the raw materials acrylonitrile-butadiene-styrene copolymer (ABS), acetylene carbon black, carbonyl iron powder and additives into a high-speed mixer for mixing, stir and mix well to obtain a plastic mixture. Wherein, the stirrin...

Embodiment 3

[0052] 1. Prepare raw materials according to the following weight ratio (×100g)

[0053] Polypropylene (PP) 80

[0054] Absorbing radiation protection accessories 20

[0055] Among them, the wave-absorbing and radiation-proof auxiliary material is composed of acetylene carbon black and carbonyl iron powder. The weight ratio of acetylene carbon black and carbonyl iron powder is 10:90, that is, the weight of acetylene carbon black is 1800g, and the weight of carbonyl iron powder is 200g. Its average particle size is 2-3 μm.

[0056] 2. Add the raw materials polypropylene (PP), acetylene carbon black and carbonyl iron powder together into a high-speed mixer for mixing, stir and mix to obtain a plastic mixture. The mixing speed is 800rpm, and the mixing time is for 15 minutes, and the mixing temperature was 180°C.

[0057] 3. Extrude the above-mentioned prepared plastic mixture directly with a conical twin-screw extruder to produce profiles of various specifications, wherein th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com